-

Dear Community,Open Source Ecology adopted the Open Source software (OSS) model of infrastructure and collaboration. From what I see, they've done a great job. I applaud those organizers, leaders, supporters, contributors, users, and readers.It is important to note that by adopting the OSS model, Open Source Ecology inherited much of OSS's nature. Open source code existed years before being called "Open Source." It existed as Unix, BSD, and a thousand and one programs, languages, and protocols. Linux became the flagship of OSS, and united much of these isolated efforts. The internet and PCs (386s from back in the day) were both conditions---perhaps necessary conditions---for Linux and all OSS to coalesce into its present form.Alright, enough history. The jist is PCs and the Internet were essential to the success of OSS. The PC afforded many people to have a computer to play with and use OSS.A similar principle bears on Open Design: Open Source Ecology included. An easy, fun, and cheap method of fabrication would function in Open Design like PCs function in OSS. Currently, fabrication in various materials requires specialized equipment; much of it large and expensive. 3D printing has changed some of these restrictions. It circumvents the need for ordinarily expensive or difficult to use equipment. 3D printing is, however, limited to plastic.If a fun to use, cheap, and well implemented (lots of OSS and Open Design backing) device existed for personal scale fabrication of metal objects, more people could contribute and benefit from Open Design. This device would open the landscape for a wealth of objects and projects. If the device worked on a 'hand-tool' sized scale, a large aggregate of people could use it. Imagine, for example, fabricating all the metal objects in your kitchen with a single device. Or, fabricating all the finely tooled components of a tractor, car, or motorcycle.There are two questions: (1) do ya'll agree with my assessment, and (2) who is---or will---work on the project?

-

29 Comments sorted by

-

Yes, magic would make everyone's life a little more exciting ;-PFor what it's worth, you can lost-ABS cast your 3D printed parts. Casting metal is still a pain in the ass, but it works just like lost-wax casting. But that illustrates the problem: some materials are just a bitch to work with, period. What we need isn't a new machine design; we need new materials.What you're talking about basically comes down to a pair of events, 1) the point where a material becomes easy to work with and 2) the point where a material becomes hard to work with. Most 3D printers use plastic because those two points are in an harmonious relationship. Metal is unusual because those two points don't align well. For the most part, any material that is durable enough to survive everyday use has a structure that precludes being easy to work into a useful shape...and that's not even touching on the issue of a single material not having a wide enough variety of properties (rigid/flexible for example).If a material is easy to work with then it needs to change state so that it's hard to work with, like melting ABS or firing clay. If a material is always hard to work with, then the tools you use to work it have to be special and expensive. A new machine won't solve that compromise; we need a new material that simply requires fewer compromises.

-

Mr. Maier,I thank you for your prompt and excellent reply. Your point concerning the two necessary properties of a material (durable everyday use, and malleable for production) is well received.Steel is a terrible material precisely because of what you've articulated. You have to get it hot, work it, and control the carbon for it to retain its important properties. The two points of everyday use and malleable are very far apart. Wrought iron or pig iron, copper, tin, lead, and a number of other metals have, perhaps, a closer harmony of points than other alloys.The basic inspiration is an amateur blacksmith. The amateur is able to produce simple products (e.g. spoons, bowls, and nails) with a few tools, a malleable media, and limited know-how.Heating could be handled with induction coils. Welding could be handled with transduction friction welds. Motivating the iron could be handled by lathing the metal heated to high plasticity. These are mere sketches of how I imagine such a device would create simple products. Suggestions are more than welcome.

-

What do you envision people making with it?

I could see a consumer machine making something reasonably simple like a pair of pliers, but you really only need one pair of pliers. Maybe two. Maybe a variety of jaws. At any rate, even if you make a whole collection of pliers you've saved maybe $50-100. If you expanded that idea to an entire tool box, like hammers and screwdrivers, and they all work exactly like they're supposed to, myabe you could save a few hundred dollars over the life of the machine. That doesn't seem like a reasonable payback period.

So, the machine would need to produce things that save more money. One possibility that springs to mind is unique, rarely-needed parts for major machines, like maybe a part for the furnace or water heater. Making it would save you from having to order it, wait for it to be delivered, and pay extra for the special part (or replacing the entire machine). But I can't imagine there are enough parts like that to make modeling them in 3D and certifying them for residential use worth the sporadic savings. Another possibility are pretty things, like really nice silverware...but I have a hard time seeing the machine making pretty things. If there's something made out of metal that is not a safety issue, and is frequently consumed, and needs to be customized, then it might pay for itself. For example, certain people put a lot of money into their hobbies, so if the machine could make arbitrary metal parts for RC cars, planes, helicopters, etc then it might pay for itself. If you could get a really good detail and surface finish it could make jewelry.

Which part of "fast, cheap, good" do you see the machine working on? Would it save people time or money? Would it allow them to customize things they couldn't have customized otherwise?

Would the machine be fire-and-forget or would it need an experienced operator? If it's the former, then it needs to provide a large enough benefit to be worth returning to the seller for maintenance (or replace outright). If it's the latter, then the benefit needs to justify the time it takes to acquire skill on the machine.

Oh, here's an idea. As a tinkerer one of my greatest frustrations is never having the right fastener. I've had to actively collect a wide variety of different nuts/screws/bolts/etc just so that I'll have the right one on hand when I need it. What if the machine could make any fastener on demand? maybe it could have a variety of wire and some way to process it into an arbitrary screw or nut/bolt.

-

I envision people making a universe of things.

I doubt the first version to be either pretty or able to make pretty things. The pretty machines and pretty productions come from the machine's descendants.

Here's another argument for the machine's utility: it should fill the niche in the GVCS 50 between the 3D printer and the CNC multitool.

Fast, cheap, and good are all possible. Given a wide base of development, all are probable. The only unreasonable expectation is for the machine to be fast, cheap, and good now. For the metal fabrication project to be successful, it would save both time and money.

Customization should be not only easy and shared with everyone, but also fun. One could always edit assembly language or G-code. It would be better to scan an object and edit that model. That scanned object could be simple clay, shaped by the bare hands.

The machine should be fire-and-forget. That's easier and more fun than being an experienced operator.

Fasteners---and other essential hardware---should be the bread-and-butter of the machine's production.

Thank you for your questions and thoughts.

-

Here's the rub: if it's capable of autonomously shaping metal into the precise shapes necessary for interchangeable fasteners then it has to be inherently complex and expensive.The complexity is required because there are so many degrees of freedom to control simultaneously. The expense is required because it needs complex mechanisms that ensure zero backlash and they all have to be strong without being heavy.It's not that such a machine couldn't be built, but it couldn't be built cheaply.At least...that's the only paradigm I'm aware of. If you have an idea for a new one I'm all ears :-)

-

Again, good point. it's one that really lies at the heart of open design, and open source.I'm paraphrasing Eric S. Raymond in his excellent paper "The Cathedral and the Bazaar." It's an excellent wealth of insight and definitely worth the read. So, the paradigm most of us live and breath is the "cathedral" paradigm. Typically, a group of professionals work on a project, keep their secrets within their organization, sell the product, and make money. They release the product for sale after it's about as perfect as this group can make it. The name of the game is make money, and keep others from making money off of you. This is how the world works (mostly).The quintessential "Bazaar" model is open source software. Here, a group of professionals work on a project, share and collaborate abundantly, explain and document the process, give away the product, and earn esteem from the community. They release early and often (or at least they should), so as to allow the community of users to assist in perfecting the product. The name of the game is to have fun, and let others have fun, too. This is how I'd like the world to work.The proposed machine would have to be a work of Bazaar art.Here are some more specific ideas:

So, in direct reply: yes---the machine has to be complex; no---it does not have to be expensive. The complexity should be handled by code, not hardware.It needs elegance. It should have simplicity in design by using few tools. Those tools, however, should furnish many applications.The tools may employ the simplicity, robustness, and versatility of blacksmithing. In this setting, you have half a dozen tools (e.g. hammer, tongs, forge, anvil, hardy, drift, and swage block) that are used to produce a multitude of things. The addition of an EDM would allow for excellently detailed work.As I've said, it should be open. The more people involved, the more the machine, processes, techniques, and software can appreciate in value and quality. Also, the first machine should just work. It needs to be a fun toy that gets the job done (mostly). More functionality can always be added later. After many release cycles, a quality machine should be expected.The first generation will probably be fairly costly, not-so-refined, and able to do a limited number of jobs passably well. As people---including the developers and users----work and refine it, later generations will be cheap, refined, and able to do a host of jobs well. Using the Bazaar paradigm, this evolution occurs very quickly. -

The complexity is directly related to how many degrees of freedom the machine has. Each DOF has to be constrained, actuated and sensed. So, the first thing to do if you want to decrease complexity/cost is figure out how to do the same work with fewer DOF.I have to say that I'm still not sure what you want the machine to do. That's kind of a problem. "Somewhere between a 3d printer and a CNC machine" isn't specific enough. Without goals and constraints the design work can't be started.Believe me, I'm a fan of the "bazaar" approach as well, but whether or not it works better isn't as important as the fact that nobody thinks it works better. Even among people who know what open source is, "open source hardware" is still relatively unknown.

-

Matt_Maier, I had to think over your reply for a little while.The first questions we're asking are "what is it," "what does it do," and "why should we bother?" Secondarily, we're asking "what are the problems?" and "how would it work?" I've mostly tried to answer the secondary questions while skipping over the first questions. I apologize for the lack of clarity.So, what is it? It's a 3D printer that makes metal things.What does it do? It does what a 3D printer does. It is a tool for making tools.Why should we bother? It's a fun problem. We could make a lot of fun and useful things with it. People could enjoy it as much as---or even more than---3D plastic printers.Those seem to be the primary questions. I could add or expand on those answers if you or the community would like.Let's take a shot at the secondary questions.What are the problems? A lot! We don't know if anyone will like the thing or use it. We don't know the design. It takes money or scrounging and time to get the raw material. I know I could use more know-how in putting it together. If it is too simple, it won't amount to much: if it's too complex, no one could build or successfully use it. The idea is too new/not acceptable/crazy.How would it work? Well, there are two rough designs, currently.One emulates 3D printers, the other emulates blacksmiths. The former works by heating the metal to a very viscous liquid, and pouring threads of it line by line. This idea has the benefit of 3 DOFs (maybe 3 and 1/2 if you count the nozzle extruding in different ways) and having a working model: the 3D printer. The blacksmithing machine works by taking a solid ingot of metal and shaping it. This idea has the benefit of making things whole-piece instead of layer by layer. The 3D printer design might have a drawback of the layers not fusing well to each other. The blacksmith desgin requires, like, 5 or more DOFs.How about some specific ideas on how it works? We're considering induction coils or microwave for heat sources. We can make the machine very smart with the image and pattern recognition open software available (not to mention a phalanx of sensors). Electronic deposition machining or etching could do a lot of detail work. What about quenching? Use the fluid for EDM or etching? Maybe just use a little pool of water or oil. But, if you use microwaves, things will get crazy unless you keep those waves in a chamber. Too much oxidation during fabrication? Remove the O2 inside the machine! Make the work area air-tight, and convert the O2 to CO2 or capture it in some material. Now, those layers of hot metal might fuse together a little better.In short, there are a lot of questions about how it would work.At least we anticipate using Ubuntu for the OS.As always, I really appreciate your support (even if it is therapeutic).

-

3D printers that make metal parts already exist. This is just one of a dozen different designs/processes

http://www.shapeways.com/themes/stainless_steel_3dprinting_galleryDo you want to simplify an existing machine? Design a new machine?Is there a reason you want to print directly into metal rather than arrive at a metal part after more than one step? Casting and injection molding are ways of making metal parts.Is there a reason not to simply use a subtractive process like existing CNC milling machines?What sort of functionality do you think the metal parts need to have? Would they be purely decorative, like a dragon statue? Would they be tools, like a socket wrench?I'm interested in a hobby 3D printer that can work with metal as well, but I've never been able to come up with an approach to building the machine that could be done by a hobbyist. The only thing I've thought of is using a plastic 3D printer and casting the part in metal. -

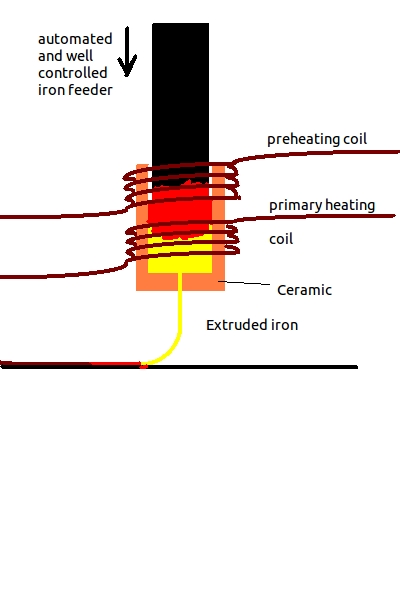

Yes, Matt (if I may call you Matt), this is a hobby 3D printer. The hope is to get around "ordinarily expensive or difficult to use equipment" as I said in my first post.We're finally sitting in the same boat. The urge you feel to build a hobbyist's machine is shared, especially here at Free Geek Arkansas. I bet it's shared by many people.We can build a DIY machine that makes metal objects like a 3D printer makes plastic objects. I've shared the idea a lot. I've grown tired of people saying 'It's too complicated!' or 'How will you make money?!' or---my favorite---'It's impossible!' Yes, it is complicated. It is not more complicated than the collective mind of our community can grasp. This machine is a gift from ourselves to others, not a money making scheme. And, it is not impossible! It is merely a small step for the imagination to take.We need to put our heads together, and start sharing.Here's where we're at, today:Use a 3D printer as the backbone of the operation. Change as little as necessary.Feed metal stock about a toothpick thick through the nozzle.Have a primary and a secondary induction coil for heating the metal. The secondary coil preheats the metal stock. The primary coil heats the stock to high plasticity for it to be pushed through the nozzle.Use a cousin of the feeding gears already on the 3D printers to push the hot stock through the nozzle. This provides a source of precise pressure at the nozzle. If you put the induction coils below the gears, you could keep the gears cool.The extruded stock flows out of the nozzle onto the bed of the printer.Now, we need to build another layer on top of the one just laid down.The nozzle moves up a hair, and repeats the process. The layers of metal need to stick to one another to improve the strength of the product. This cohesion (fusion, really) is prevented by three things: heat of metal, surface oxidation, and physical force needed to join the metals. The heat could be provided by the hot metal extruding from the nozzle (this source of heat would be present, anyway). The prevention of oxidation could be handled by burning up the O2 available, or displacing all the gas with something that doesn't oxidize. Finally, a piezoelectric hammer (metal slug with a piezoelectric material on one end complete with wires) could provide that little umph necessary to physically motivate the older layer of metal and the new hot layer together.Layers are laid upon layers, and a 3D object is slowly built up.Perhaps some sketches of designs would help. I'll see what I can do.- Joe

-

Here's some work the RepRap guys are doing on directly printing metals

http://blog.reprap.org/2011/06/new-approach-to-printing-metals.html there are some obstacles.My first guess is that as long as the metal filament isn't hot enough to melt you'll have way too much pressure in the nozzle, but that if it is hot enough to melt it will just dribble out of the nozzle without control. I don't think metals have as nice a plasticity zone as...well plastics.I'll help develop the idea if you show me where you're at. -

Excellent post, Matt_Maier.The RepRap crew printed metal! Very exciting. They used an alloy that is very compatible with their plastic setup. I'd guess that the tin, indium, and bismuth alloy is well suited for thermal/electrical conductivity.One of the goals we started earlier is to make tools, including tools that can handle a serious mechanical load and an open flame. Something that's mostly tin can't reach that goal. Something that's mostly iron or aluminium can. Let's just assume we're working with iron.Take a look at a simple phase diagram for iron <http://dao.mit.edu/8.231/PurePhases_files/img23.gif>. Given the low pressure we're working with, delta iron is our window of plasticity. It crystallizes at 1,538 °C (2,800 °F). That sounds like fun.Here's where we're at. See "extruder" bellow. The preheater gets the metal hot, and keeps it hot. The prolonged heating breaks up the metal grains (i.e. crystals), and makes the primary coil's job easier. (Broken up grains is the iron being more plastic. The right temp. is not the only concern with metal plasticity.) The iron is fed into the ceramic nozzle. The primary coil raises the temp. to high plasticity. The molten iron seals well inside the nozzle. When metal needs extruding, the iron is pushed down, forcing the mostly molten iron out. When the system needs to stop extruding, the iron is pulled back, creating a suction inside the nozzle. The heat source is induction wires which heat the metal from the inside out, while they stay room temp.This design would require precise control to extrude mostly (almost 100%) liquid metal. An advantage is using cheap and readily available iron.- JoeAttachments

extruder.jpg 57K -

Okay, sure.It's entirely possible to get some ceramic that will survive having molten iron pushed through it http://www.filtec-corp.com/Extruded.htmlAs for extruding molten iron http://en.wikipedia.org/wiki/Extrusion#Hot_extrusion it doesn't seem like a residential activity. Thousands of degrees and hundreds of tons. At a minimum, this would be a shop tool; equivalent to a professional CNC machine. On the other hand, perhaps it would be possible to just skip the extrusion step and go straight to welding. If you passed the wire through the heater until it reached the correct temperature, then it should bond with itself (right?). It's the pushing the large rod through the small nozzle that creates the pressure, but maybe that's unnecessary. The 3D printers that use plastic do that because they need a plastic wire that's thick enough to act as a piston when you push on it, which the tiny extruded noodle is too thin to do. But metal is a lot stronger. Maybe the raw wire can already be the final diameter; just heat it up and squish it into itself.Some welding tools already have an automatic wire feed and use the wire itself, along with high current, to create the heated arc that melts the metal http://en.wikipedia.org/wiki/Gas_metal_arc_weldingMaybe a welding gun could simply be mounted on a CNC machine. Rather than weld two pieces of metal together the deposited metal would be allowed to build up in layers, resulting in 3D printing just like the plastic printers. You wouldn't even need any new machinery to test that, just a CNC machine and an appropriate welding gun. You probably wouldn't be able to print onto a build surface. Most likely you'd have to have a sacrificial layer of metal that becomes part of the finished piece. Maybe you could print onto a bed of powdered metal.Either way, if you want to print layers of metal like plastic you're probably going to have a heat problem. When the plastic doesn't cool fast enough the layers tend to distort and it seems like the metal will take a lot longer to cool down. You'd probably need some kind of forced cooling, or just wait a long time between layers.

-

Matt_Maier,Good thoughts and good links.I, too, share some serious doubts about the extrusion process. If you wanted to lay down a lot of metal, the pressure would have to be very high. High pressure means heavy duty ceramic filters, supports, and high cost of materials.I think the direction you're headed with the fed wire is more adequate.I'm pretty sure the arc welder/CNC combo would work. We might have a work around of the heat problem and the large set-up with a different welding system.As you've pointed out, arc welding requires the expulsion of oxygen, nitrogen, and water vapor for a good weld. Forge welds, like ultrasonic welding, push out oxidized metal and sundries as flash. No need for shield gases or arcs of electricity. Spot welders, like this, have been around for a while. A continuous seam welder/splicer is what this application would be. Additionally, the parent metals could be very cool, like room temperature.Here's a sketch.I'm hung-up on induction coil heating, apparently. I think relaxing the metal would better marry the layers prior to welding, allow tight corners, and lessen the mechanical strain on whatever feeds the wire. Iron wire would be fairly flexible above red hot (500 F), but would lay down well if it were yellow or white hot (pushing 2,600 F), so we have wiggle room. Tweaking would be necessary for finding the right balance between too much heat and too much rigidity.

-

It seems like the ultimate utility of the printed object will depend on the crystal structure of the metal. We might be able to get the wire to adhere to itself and still leave a "grain" that severely weakens it. We need the new metal to seamlessly bond with the old metal. Since we can't deal with the necessary pressures, like a hydraulic ram or a hammer, we have to use heat. The metal needs to be hot enough to flow together without becoming so liquid that it runs uncontrollably.My intuition is that if the metal gets to the right temperature we won't need to force it together physically, but that temperature is probably not easy to achieve or maintain.What do you think?

-

I agree upon essential role of cohesion and grain in any product.Concerning cohesion: we opt for a wire fed system, which has little cohesion between layers. Without welding, the only cohesion is (potentially) one wire merely wrapping and laying upon itself and the grip the faces of the wire have upon one another. This design benefits greatly from welding layers together. If the surfaces of the wire were devoid of impurities and oxidation, one could merely heat them to sufficient plasticity and press the surfaces together. The force required to join parent metals in this fashion is quite low (blacksmiths do it by hand routinely). In our model, we'd make and keep the wire completely clean, layer it atop itself, and press it with a little mechanical force. Some induction heating coils, pyrometers, and C code could handle the heating fairly precisely (give or take 3 degrees C). Mechanically joining the layers wouldn't be too difficult, either. The big problem I foresee is cleaning the surfaces. Arc welders keep things clean by displacing air with various gasses. We could repeat the same process by "welding in a jar": clean the metal; then heat, lay, and weld it all inside some environment devoid of oxygen, nitrogen, and water vapor.Or, we let the weld do the cleaning for us. This is a big reason why I favor the ultrasonic welding. The surface impurities, oxidized metal, and sundries are forced out of the weld as flash. With ultrasonic welding, we could weld outside of a jar.Concerning grain: I'd expect our latest sketch would actually have very large grain, thus a product that is very rigid. The quick heating, minimal welding, and long cool down would do little to reduce the grain size, if not grow the grain. So, we're left with a hard metal as our product.Ideally, we control grain, temperature, shape, size, and composition as well as the master blacksmith. This, at least, entails normalizing the metal (as precisely as we please), welding, tempering, and cold working the metal. I agree that better products require better techniques. These techniques are essential features. Perhaps we could think up categories of essential features, and how to build those features (i.e. capabilities) into the machine. For instance, if we want to normalize the product (or a section of the product), we need to heat an area for a given amount of time. Normalizing would probably come after printing the layers and welding them together. This means either reusing the heating system used to heat the wire in the first place, or having another heating system.

-

Some automated processes do "submerged welding" where the weld is covered by a pile of powdered flux. That keeps all the oxygen off of it and the flux keeps the metal clean.Is there an advantage to an induction coil over an arc welder? Seems like induction coils require forced cooling, which arc welding doesn't. On the other hand arc welding requires that the work piece be part of the circuit, which isn't required in induction coils. Seems like there has to be some sort of lower limit on how small you can make an induction heater before it can't be cooled fast enough to keep from melting itself.Heat treating usually takes place in purpose-built ovens. I suppose if this is going to be a pro-sumer level machine it would have to be able to do heat treating itself. I can't imagine the oven is all that expensive.

-

Yes, Matt, lot's of questions.

Let's handle an easier question: an over could work just fine. We could use an over to heat and cool evenly, control the atmosphere the metal is worked in, and provide a nice barrier between hot bits of metal and people.

Welding is a big issue. I think we will have to do some simulations to answer your questions about submerged welding VS arc welding VS induction coil/ultrasonic welding.

By the way, I like the term "pro-sumer" you used.

-

The layered welding thing could probably be tested by just going to a metal shop and asking the oldest guy there if he knows of any way to gradually build up the thickness of a weld.Maybe it could use metal wire but instead of mashing/melting it together it just bends it into position and then brazes it in place.

-

Rather than extrusion, consider tape layup. You have a roll of metal strip or foil. It goes through heating rollers or a chamber that heats it just below the melting point, where it's soft enough to flow. Then it goes under a pressure roller or stamp that presses the hot strip onto a previous layer to bond it. To build larger objects you just lay more layers.

-

I like the tape layup idea. How about something like this:

Foil sheet, or perhaps standardized plates, are cut with a laser to the right shape for the layer. These layers are built up to form the object. In between the layers, a thin layer of a brazing alloy is deposited. It could be through electrolysis, chemical bath deposition, being sprayed on, vacuum deposition, etc. Then afterwards the whole piece is heated up to complete the brazing process. You might even be able to get away with building up the layers then just submerging the whole thing in brazing alloy...that would be ideal.

If the amount of clearance between layers is very small, then the joint will be strong (people say it can be stronger than a weld potentially). You will also avoid warping the piece or similar nasty things because brazing produces a much cleaner joint than welding. Maybe something like vacuum brazing would be ideal, since you can heat treat in one thermal cycle and don't have to worry about oxidation.

Here's a good read on brazing. Some key points they mention are:- -Brazing is better for small assemblies

- -Thin material

- -Larger joining area

- -Brazing lends itself to automation

- -It is more attractive visually. The discontinuity between layers would be filleted, and it often requires no finishing

- -Brazing is better for small assemblies

-

Adding on to the above, one option which would simplify the process is to pre-coat your starting material with the brazing alloy. For example, imagine your starting material is 1 mm thick steel plates which are nickel-coated on each side to the appropriate thickness. Then all the machine has to do is cut each layer, stack them, and heat. That's not bad at all.

-

I like that idea. Maybe you could have some kind of flux that binds the plates together so they don't shift. Then submerge the part in the brazing metal and have it replace the flux? Would you have to mechanically keep the plates aligned during the process to ensure they didn't shift?Whatever is used to cut the layers could be "tuned down" to heat them and attach them to the previous layer, then be "tuned up" to cut the next layer.

-

Many of these ideas have already been discussed in the RepRap project WIki and forums. The most likely candidates for metal fabrication are:

1. Selective Laser Sintering: Uses a high-powered laser to sinter powdered metal feedstock. This can produce full-strength parts at AT/AP, but they are not finished parts.

2. Electron Beam Melting: Uses an electron beam in a high vacuum to sinter powdered metal feedstock. This can produce full-strength parts with finished quality and low internal stress. Unfortunately, vacuum engineering is not easy, and producing a high vacuum is not something the typical user is able to do.

3. Ultrasonic Consolidation: Uses an anvil and an ultrasonicator to weld sheets of foil together. This can produce full-strength, finished parts, but requires extremely high pressure from the anvil, requires the sheets to be pre-cut to shape, and there is no easy way to do overhangs.

The problems with the ideas discussed thus far:

Metal wire:

Metal is harder to run through a pinch wheel, which is the preferred extruder drive for low-cost printers.

Metal FDM:

The glass transition window for most common metals is very small, requiring precise heater controls. It also requires measuring the temperature of the hot zone internally, especially if there is lots of insulation like a glass or ceramic nozzle. Glass nozzles are transparent to near infrared, so an infrared sensor is possible, but it would still require a high-performance heating element and control.

Arc welding:

Produces a lot of spatter, lots of external heat which will rise and cause cooling issues.

The most promising tech for RepRaps is Electron Beam Melting, which is the focus of the MetalicaRap project. They have completed design for a power source, with a significant cost reduction (~$500 rather than >$1000). They are designing the electron gun, and are doing research on the vacuum chamber, IIRC.

The RepRap project site is a very valuable source of information, and there's no need to reinvent the wheel, when it comes to open-source =)

-

MIG welding doesn't splatter, and all wire-fed welding processes use a pinch wheel to control the metal wire. EBM requires a vacuum, an electron beam, and powdered metal; even if you can make it cheap that is an industrial process, not something you'd have in the garage.

-

From what I read on the RepRap forums, pinch wheels are limited in the smallness of the filament they can drive. Further, driving metal requires higher torque, especially when you want to extrude faster. This means there is a limit on both the speed and resolution of MIG-welding based manufacturing; It's well below industrial engineering tolerances, which is what you would want to make full-strength parts for.

Doing a quick Google search, it seems that MIG welding does indeed spatter, though there are shields that prevent this from happening. It also requires a supply of inert gas.

Powders allow you to make alloys much more easily, they act as support material for overhangs, and EBM is capable of producing CIGS solar cells, and it makes high-resolution, extremely dense parts with no voids and finished quality. Another advantage is that there are no moving parts.

EDIT: Discussions on the RR forums about full-strength add. man.:

http://forums.reprap.org/read.php?70,35220

(In the comments section) MIG welding would require an extra axis on the toolhead, which further lowers its precision/repeatability.

This thread contains links to some good journal articles about addman techniques.

This is the newest discussion on full-strength manufacture.

-

Oh look, somebody's already done it

https://repositorium.sdum.uminho.pt/bitstream/1822/3038/1/20%20IEE%20Computing%20&%20Control.pdfEven the major players haven't figured out a way to create full-strength parts using rapid prototyping processes. I'm not saying don't go for it, I'm just saying that they've been throwing a lot of money and education at the problem. There's no such thing as a broken manufacturing system, there are just compromises. Metal is hard to work with. That's why it's so useful once you do put in the effort to work with it. If it was easy to work with, the result wouldn't be useful.Also, you don't "extrude" metal wire when you're welding. You just feed it through a tube. It never changes shape, so there's no torque problem. -

Has anyone considered metal sintering? A furnace has no moving parts to hold position and does away with combining precision machines with temperatures over 2000 degrees. I would think it is possible to use lost wax casting or conventional 3D printers to produce the part cavity(s) or molds.

The disadvantages would be gaining the expertise to determine the right type of "polymer" to mix with the powdered substance you wish to use; cast iron, stainless steels, ceramics. etc. This substance is burnt off at a lower temperature before sintering, which results in the parts shrinking about 20%. Without removing the part from the furnace the temperature is then increased to the critical temperature which allows the molecules to fuse together. Obviously this also may result in a part that requires some secondary machining to get smooth surfaces, precise geometry or dimensions. I know cast iron powders when it is machined but whether this is small enough for sintering I don't know.

I suppose the biggest drawback is the "Golly - Gee" factor of seeing your finished part emerge complete from the machine in one fell swoop.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Ackhuman July 2012

- blade October 2012

- danielravennest May 2012

- Jason May 2012

- Joe_Moquin May 2012

- Marty0 September 2012

- Matt_Maier July 2012

Tagged

- 3d 10

- fabrication 3

- sexy 1

- cheap 1