-

I have started a new category in the wiki for "Bootstrapping": http://opensourceecology.org/wiki/Category:Bootstrapping . The concept is using the tools you have to make better tools. The GVCS set as a whole are an instance of bootstrapping, but at the industrial level. Before you can build the first GVCS machine, you need some kind of workshop and lower level tools, which is exactly what Marcin did with his first workshed.

I'm starting to set up a community workshop on OSE principles in Gadsden, AL, and the first thing I wanted to make was "grid beam" type wood pieces to build workbenches and storage shelves. I discovered I needed a drill press for that, and since I don't have one, I am doing a drill press conversion based on this Instructables project. So upgrading a hand drill to a bootstrap drill press is an example for this category. I plan to document the whole design and construction similar to how the GVCS machines are being done, followed by how to make the grid beam parts and build workshop furniture with them. Larger grid beam parts can be used to make entire modular buildings, which is why I am concentrating on that subject early. 14 or 40 steps later, when our community shop gets to the level of power cube and the GVCS drill press, we can upgrade from the bootstrap press, but I think we need to document a path from just hand tools to where you can make the serious machines.

Woodworkers have a saying for this: "you need a workbench to build a workbench". Really what is done is you make a makeshift bench from two sawhorses and two planks, and use that to cut the parts for a sturdy but simple bolt together bench, and in turn use that to make the parts for a higher quality woodworking bench, from which you can make any other wood project. Ideally the bootstrapping category here will cover the other materials that need processing besides wood to develop a general purpose shop, rather than just a woodworking shop.

You might ask: can't you just go out and buy the needed tools? Yes you can, if you have the money. You can hire someone to build you a workshop building, buy a plasma torch table, and a good quality industrial drill press, and a welder, and jump right into making industrial level machines. But not everyone is in a position to do that. A community workshop can start small by making furniture and cabinets, and doing remodeling work (building decks and such) to raise funds to buy the next level of tools and materials and expand the shop. By splitting the cost of the initial minimal hand tool set, that should make it feasible for anyone to get started. A community organization is yet another "bootstrap" tool.

Please add your own ideas to the bootstrapping category. There is actually a lot of information out there on do-it-yourself tool building, but it's scattered, and not organized as a coherent series of "Build A and B, which lets you then build C, D, and E", and usually it's focused on one category (woodworking, blacksmithing, etc), rather than a generalized shop that can do multiple categories. I know there are holes in my knowledge and skills, so I need help filling them.

-

24 Comments sorted by

-

I had roughly the same thought while reading about how to make a machine shop with a DIY furnace and scrap metal. Even though the plans start out quite simple, they still require pre-existing tools like a straight edge and files. Not to mention scrap metal that's already been purified...I'm sure someone somewhere knows how to smelt and purify metal in their backyard, but I don't. The whole thing implies a hierarchy of knowledge which, once completely filled in, would ensure you always knew how to get from whatever tools/materials you have to the tools/materials you want.

-

Actually I do know how to smelt metal in my back yard, but that is because I'm interested in history and have a copy of the "Oxford History of Technology". Making iron just requires stealing oxygen from iron oxide (Iron ore or rust). Historically that was done by creating carbon monoxide, which has a greater affinity for oxygen than iron does. The carbon monoxide comes from burning carbon as charcoal or more recently coke, which is coal purified of the elements besides carbon by partial burning. Charcoal is the same thing starting from wood. You burn either in a furnace with sufficient air supply to raise the temperature above the melting point of iron, but not so much air all the carbon goes to CO2, you want some CO from incomplete combustion. The iron will collect at the bottom of the furnace because it's heavy. You layer in charcoal/coke with iron ore. In a backyard version it will run in batches. Modern blast furnaces are just bigger versions of this device, with conditions optimized and designed to run continuously.

So, starting from nothing, you make some clay bricks by hand, and fire the bricks by building a fire around/under them, or, alternately dig out a vertical shaft in a hillside of suitable rock and fire it from inside. You need a horizontal opening near the bottom to feed air. Stack the bricks in a chimney like arrangement with an opening near the bottom, and surround with more dirt for support and insulation. Make a box bellows from wood boards and a clay pipe to feed more air into the furnace. Load charcoal/coke and ore in layers, and fire it up. A little limestone added in helps collect impurities into the slag that floats on top of the iron (it's less dense), but it's not required. If you do it right, the iron will collect at the bottom of the furnace. Your air inlet should be a little above the bottom, and the bottom bowl shaped. Once you have two lumps of iron, one can be your anvil, and the other attached to a stick to be a hammer. You can re-melt your iron in a clay crucible and pour it into a mold to make stock shapes.

Making straight edges requires making three rulers, which you test against each other in succession. If no light shines between them then they are all straight. If there is a curve, then A may match B and C individually, but then B and C will not match when you flip B over, because you have now mirrored any deviation from an ideal straight line. When you have one edge straight, you can make the other side parallel by using a fixed gage, and grinding down the spots that don't fit the gage. With several rulers, you can make a flat surface by looking for gaps under a straight edge at different angles, and by placing pairs at opposite ends and sighting along the top to detect any twist. Round things are easy by just mounting on a spindle and rotating. With round and flat surfaces you are on the way to making basic machines.

All of the above may be interesting to know about, but likely irrelevant to anyone reading OSE materials on the internet or off a DVD. If you have access to those, you likely have access to a source of electricity and steel, and can start at that level, rather then making iron from scratch. Steel, by the way, is iron + 0.2 to 2% carbon. The carbon makes it harder, so better for structures and tools, and enables "hardening" by a specific temperature cycle that affects the crystal structure. It's easier to shape in the soft state (annealed) and then harden if you are making parts or tools that need to last against wear. If we extend the the Global Village idea out to developing areas without internet/electricity/steel, which is a shrinking fraction of the world, you need to deliver the info on paper, or by mobile phone. Something like 5.6 billion mobile connections are in use, which is not far from the 7 billion total population. I do think we should think about minimal starting kit for developing regions, but I'm not sure if minimal means smelting ore locally. It might mean a box with manuals and enough basic tools and parts to get started, and instructions to scrounge scrap iron, cut wood from local trees using included saw, etc. I think a key part of bootstrapping is augmenting human power, so supply various ways to get from hand and bicycle type drives to windmill, waterwheel, solar steam, etc. drives. Another key part is upgrading agriculture so they don't have to spend 100% of their time just staying fed. You need surplus time after feeding yourself to work on anything else. So maybe your starter kit includes seeds for fruit and nut trees, or a plow blade. I can't say exactly what, but it's worth thinking about.

-

You've outlined the basic process for making iron but there is a big gap between making steel and making iron, ESPECIALLY if you are going to be starting from scrap steel, and even more so for making aluminum from scrap, because in reality, the most useful metal products will not be pure iron or aluminum, but rather specific alloys of them with other metals & minerals.

I've tried to communicate to Marcin that even if OSE were to get to a GVCS induction furnace, that doesn't yield metallurgy, just molten scrap metal... I'm not sure that message was well received if at all.

As far as iron smelting, yes, you mostly burn off the impurities, and then ADD back various elements that are needed to produce the quality and combination alloy that you're looking for. It can be a messy and energy-expensive process.

Aluminum will melt at much lower temps, but it is so much more reactive than iron, that it will be chemically more difficult to purify, it will need a much more controlled atmosphere/environment with no oxygen available, or something that is more highly reactive than it to steal oxygen from it, in order to purify it. I really don't see an amateur attempt making anything more than low-quality aluminum if melting it is all they are set up to do (no T-6061, or similar alloys), and they'd have unknown strengths/durabilities/chemical properties/etc.

AND every batch would be different!

The Dave Gingery book series is a good one for starting with pretty much nothing, and building to a usable set of tools, but he doesn't really get to iron smelting (he starts with a charcoal furnace & aluminum melting/casting). One will have to scale that up to get serious about durable tooling, but it's a start.

Starting from scratch may be better done with something more akin to building an Earthship, because at least then, you can cover the basic shelter, water from rooftop collection, and get a start on food production for living. You would need glass, though, or something for transparent windows for the concept to work. Perhaps they could be scrounged too?

-

Could you link to a copy of the Oxford history of technology you mention? I can't find anything by that name.

All of that is EXACTLY what I mean about filling in the gaps. It's not about being ornery and doing everythind yourself "just because." It's about figuring out where you can compress the industrial system into a smaller footprint. Maybe some things just plain work better as massive, centralized facilities. I have a hard time believing these little 200-person OSE franchises are going to be able to produce everything they need. There are plenty of exotic "vitamins" that are impossible to make; you have to just dig through enough stuff to find them. That means mining and that means not only do you have to settle in a place with concentrations of those elements, but you have to devote people and space to digging them up.

Is that just an old-and-busted paradigm? Is it possible to get all the iron ore you need out of a little mine if you're clever enough? I dunno.

Maybe it doesn't even make sense to focus on iron and aluminum. Maybe if self-sufficiency is that important we should go back to copper and bronze. The Iron Age didn't come until later, after all. There's a lot you can do with metals that are easier to gather and work with. So, in the same way grass pellets aren't as energy dense as fossil fuels, but they are prefferable because they can be sourced and refined locally, maybe OSE should work on local bronze production.

The sort of information we'd be looking for is old enough it's free http://www.farlang.com/gemstones/agricola-metallica/page_001

You can go either direction. Since we're starting in the middle we can go up and down the tech curve at the same time.

-

@Matt_Maier - here is a link to a copy on Amazon. (http://www.amazon.com/History-Technology-Five-Volumes/dp/B000TTPGEM) I own 3 of the 5 volumes in the original hardcover, picked up over the years in used bookstores. I don't think self sufficiency in the sense of making all your own stuff is the goal. I see it as making enough of your own stuff to cover basic needs, so that you are not at the mercy of getting laid off by a faceless corporation and losing your home. Working a paid job becomes optional, or you work for yourself and your neighbors, producing extra of something you like doing.

@Allen15 - I don't expect OSE type projects to meet 100% of people's needs. What I expect is we can get to something like 80%, and then diminishing returns set in for things you don't need as much of or are harder to make. For example, in building a house, we can reasonably expect to make lumber and cement, bricks, and earth blocks, and thus make the bulk of the structure. Home-made light switches and outlets don't make as much sense, since they are pretty cheap. For the 20% that is not practical to make yourself, you just work a regular paid job, or sell surplus production of what you can make, ie sell lumber, furniture, excess food, etc. and use that to buy items you need.

I'm aware that raw iron, cast iron, and various grades of steel are different, and was not recommending trying to make them ab initio. Even in developing countries, you can probably scrounge up some existing metal, and in Western nations like the USA bar and tube stock is readily available. The question is how much of the value of the finished item is in the stock, and is it worth the trouble to try and go earlier in the chain towards raw ore?

-

Thanks, I just added it to my birthday list :)I agree on the 80% thing. That's a nice round number that I use a lot to express the idea that perfection becomes destructive after a while. It's better to do 80% of everything than 100% of only one thing.Personally I really like the idea of OSE technologies leading to a proliferation of micro-industry. Kind of like how China put a furnace in every backyard...only without the Communism part. I'd actually subscribe to a version of twitter that connected a huge "social" network of micro-fabricators. Since they'd all work in small batches, and would tend to work "approximately whenever I feel like it" you'd need a whole network of them to become a real alternative to the Wal-Mart model of centralization and just-in-time stocking. They could tweet things like "just finished a 1 ton batch of flat bar" or "need 5x10 feet of angle aluminum in three days" or something like that. Once the network reaches a critical mass you'd be able to go to it pretty much as easily as you go to the home improvement store. Like Craig's List.The networking would reduce the minimum volume necessary for investing in the infrastructure necessary to do micro-industry.I wonder how liberal the zoning laws have to get before they'll allow you to run an automatic forge in your backyard.

-

> I wonder how liberal the zoning laws have to get before they'll allow you to run an automatic forge in your backyard.

I'm not aware of restrictions that prevent it - at least in my part of upstate New York. Certainly hand forges are allowed. Perhaps it's a matter of scale.

- Mark

-

I guess I was thinking noise/air pollution in general and zoning in particular. For example, my understanding is that it's pretty common for zoning to prohibit more than a certain number of adults from living in the same house without having a renter/rentee type of relationship. That could put an upper limit on efficiencies of scale at an OSE-type village. No dorms, for example. Maybe the structure could just be a low-cost co-op or something.

-

Where I live (Chicago burbs), there are zoning laws that would prohibit more than x number of families living on a single plot, based on that plot's zoning, and it is also illegal (here) to keep chickens, among other things. The backyard forge could easily fall under fire from the anti-nuisance laws too, as it would only have to offend 1 neighbor enough to complain about the sound, smell, etc., before one would be cited.

I can't do a backyard forge here, I'll be lucky to get by with a greenhouse, because everyone is scared about "lowering their property values"...

-

@Allen15 - I take it as a given that in city areas an OSE project would have to be a "community fabrication shop" located in a properly zoned area like warehouse or industrial. You might have individuals sharing the space, each with a sub-area they can close off, but having people in proximity helps with delivery and mass purchase of supplies. Even so much as running a circular saw in your garage on a regular basis can piss off overly sensitive neighbors in standard suburbs. For growing food, I assume you would get land further out. Factor-E Farm appears to be in a rural/agricultural area, so those kind of issues don't come up.

The zoning rules are there for sound reasons. The sizing of water supply and sewer systems are based on a certain number of people using the system. If you are determined to stay where you are, about all I can suggest is doing an attached greenhouse and calling it a "sun room", or building as high a fence as you are allowed, and keeping the greenhouse and plants low enough to stay hidden. But generally suburban lots are too small to grow more than a supplement of food, so concentrate on high value items.

-

@danielravennest - I'm not dead-set on staying where I am, in fact, I'm looking forward to the day I can move off into the wilderness & get away from it all permanently, but my business keeps me here for a few more years.

I am not limited by the size of the yard, as the back yard is close to an acre, and the adjacent back yards are also not fenced, so I have a great deal of open space. To my north side is family who is looking forward to the greenhouse produce, and to my south side is vacant, possibly to end up being bought up by family. I still can't get past the local zoning laws, as this is one of the more precocious suburbs, and they tend to lean toward the snooty side, where they really don't want their neighbors to do ANYTHING that might cause their property values to drop, especially now. The local zoning laws here are more focused on not overloading the local school system, as the water system isn't really overstressed.

My greenhouse wouldn't be visible from street view.

I recently met a neighbor around the corner (on a dog walk), and when they realized where I was living, they asked me about our recent back yard tree removal. I was invited into their back yard (they also have a new puppy about 1 month younger than ours), and I realized that our yard was uphill from theirs, so my proposed greenhouse would be their main scenery from their back yard... Guess I need to make sure that side is pretty?

I'm planning on building a 40' x 40' greenhouse, not because I can't build larger, but rather because I may not be able to afford to build larger than that. I have space to build about 40' x 100'. I'm sure I could feed my family plus most of the neighborhood in a 40' x 40' greenhouse, (if it was properly run & managed). That is much larger than the typical home greenhouse. With aquaponics, I could seriously look at completely replacing my family food sources if pressed, though we'd have to learn to live without beef, pork, or poultry, & just live on fish & vegetables if need be. I think I could probably even sneak a few hens into the greenhouse without raising too much fuss, but if caught, they'd have to go. I think I can even get a few rabbit hutches into the greenhouse too.

FactorE Farm is in farming country. It is farmland surrounded by more farms. Nearest town is a tiny farming town, about 3 miles away, so yes, they can pretty much do whatever they wish to, without bugging their neighbors too much. In my neighborhood, there really isn't a high percentage of folks who would even be willing to get their hands dirty doing manual work - (that sort of thing is hired out, don't you know?), so I won't get any sympathy from the community at large (here).

For the time being, I must accept that I really don't have practical, ready access to anything resembling a good shop, and that I will have to move to change that. I can still grow the majority of my food, though.

-

OK, your yard is bigger than typical suburban ones, which are more like 1/4 acre. One thing to think about is using modular construction for your greenhouse. Then when it comes time to move to your future home, you can disassemble it and take it with you. Modular means things like bolted together frame and glass if that's the kind of construction, so it can be taken apart, and using standard size parts and hole spacing.

Meanwhile, almost got my bootstrap drill press done. Out of pocket cost so far is around $40-50, not counting scrap wood I had lying around. I have started to document it in the wiki, but still need to do most of that, and testing it once I get it done.

-

OK, got drill press done and did my first testing today, a bit later than expected. I don't have a usable workshop yet, so I work on the front porch, and the weather has not been cooperating. I'm now getting into documenting the parts list, assembly instructions, drawings, etc on the wiki, while also using the press to make "Grid Beam" type modular construction parts. The goal is to make a portable shelter on the porch so I can work more of the time, and later move that to the land/house I will get someday. Since it will be modular, it can be disassembled to move it, or modified as needed. Bootstrapping buildings from portable shelter -> standalone workshop -> house gives a path to developing bare land in parallel to building better tools.

-

Cool. Let us know how the Grid Beam approach works out. I've been thinking about something similar but without pre-drilling all the holes.

-

That's what I am doing. Drill what holes I need at the time, but make them at uniform spacing (i.e. 1/2 inch from the end, and 1 inch intervals) so if you recycle the item, it will still fit the next project. I did a test joint, and that seems sturdy enough. To make larger items you need plywood or other sheet goods as a facing for rigidity (that's how regular 2x4 and plywood home construction gets it's stability), or diagonal bracing. So I'm going to be building a variety of items for the shop (storage shelves, workbench) that I need anyway, and see how it works out.

-

One of the things I was trying to figure out was how to incorporate flat sheet into the standardized grid spacing of the beams. A rather obvious way to beef up the strength of the 90 degree joints is to include a triangular piece of sheet material in between the beams. The problem is that offsets one or more beams from where they would have been if they were adjacent to each other. I was thinking if the width of the beams and the thickness of the flat sheet was chosen to compliment each other, then the holes spacing could be based on the combined measurements. For example, keep the hole spacing on the inch, but make the beams 1/8 inch thinner on each side. That way, when you put two beams next to each other, they have a 1/4 inch space between them, into which the flat sheet goes. Any time you don't intend to use a brace you just put a small 1/4 inch spacer between the beams.

-

The key thing is to define a consistent spacing so parts will always fit. That is how LEGO blocks work.

I'm in a rented house with a garage, but the garage is full of stuff, including raw lumber (which came from hiring a guy with a sawmill at a previous place I lived). So what I am doing is making modular panels to enclose part of the porch, so I can work through the winter, and later use them elsewhere, like a separate portable building in the yard. I'm making the panels 4 ft wide, with the intent to bolt them together both side to side to each other, and top and bottom to longer boards for stiffening. These panels are not intended to be disassembled, so I will use lag screws for the framing. The idea is 4 ft panels are about as big as one person can handle, and a reasonable size to build with. Smaller stuff like workbench and shelves will still be done like the grid beam system. Checking my timber framing manual, the bolts should be spaced 10-12 times the stud thickness to get the full strength of the supports. Since they are full 2x4 (not planed down to 1.5x3.5), that means 2 ft spacing of bolts vertically. I still need to figure out the horizontal spacing for the top and bottom stiffeners.

Mostly this is an experiment to see what works, and most likely I will get some useful items out of it. If I can use up some of the lumber and then move stuff out of the garage, then I can start setting up a proper workshop. This is all part of following the "bootstrapping" concept, because that's exactly what I am doing, starting from typical homeowner situation of ordinary tools and no real shop.

-

that's an important point about lego like modularity, i had a quick look on the wiki and couldn't find any obvious talk of standards and sizing - as probably the leading open source engineering project isn't it important that OSE helps to forward some standard's?The wiki has this, http://opensourceecology.org/wiki/CAD_Standard_Sizes but it's only got one section filled in. The GVCS.01 has plenty of info about meeting standards for being included and etc but i couldn't see anything with any actual numbers - i've rolled through the wiki a lot and i don't remember ever seeing more so if it is there it's certainly [probably] not prominent enough.You two are both working on things which interface with the GVCS, do you think that a nice clear list of general standards would help? I'm thinking just a general 'try to use m-profile threads where possible' type of list, this appeals to me because if you're designing something (like a workbench) and need four nuts they're coming in a bag of 12 - sure nuts isn't a great example because the standards pretty much globally fixed now but for some things i'm sure knowing what'll be useful later and what almost identical thing wont could be a great help.

-

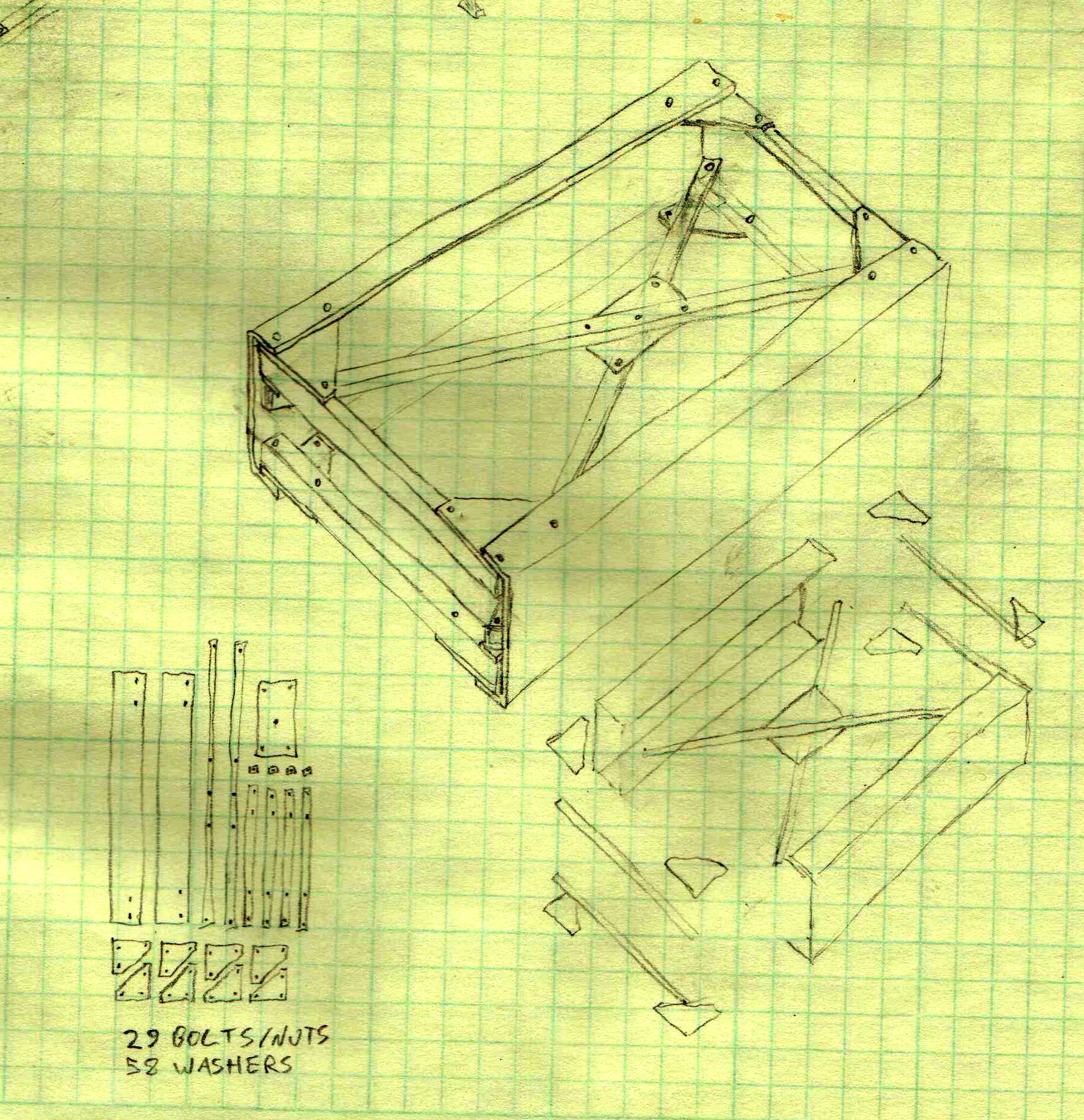

I've been working on a unified concept for a full-sized parts kit. Not so much Legos. More like

http://eitechamerica.com/ or

http://www.knex.com/ or

http://technic.lego.com/en-us/Default.aspx although that is made by Lego.A big part of the problem is that I don't have the math to figure out whether or not a kit like that would work at 1:1 scale. I assume it would as long as the pieces are based on the size/type of pieces already used on non-kit based 1:1 vehicles/machines. At any rate, it would be a start.Personally I think it's the only way for the GVCS to really achieve the economies of scale that are necessary for it to be competitive. I posted a link somewhere on the wiki to an article where a bunch of enterprise guys answered a poll about why they chose open source server software instead of vendor-supplied software. The overwhelming response was that they preferred the freedom. Low price was an answer, but it wasn't the most poplar one. The average person chooses open source because it's free. Professionals with big jobs to get done choose open source because it doesn't lock them into dependence on a particular vendor.For the GVCS to become popular it needs to maximize that freedom (as in speech, not beer). Building the whole thing out of a kit of modular parts would go a long way towards getting the attention and interest of the sort of people who will adopt it. Some people never will, and some people never should. It will always be a specific solution to a certain kind of problem, not a universally applicable way of life.So...obviously that strongly implies bolt-together construction. Welds are pretty much permanent.It also implies working with commodity parts as much as possible; flat sheet, angle iron, c-channel, tubes, etc.It also implies building simple shapes and only begrudgingly forming more complex shapes out of simple shapes.Here's an illustration of what I mean. It's a generic vehicle frame. The primary stressed members are the big c-channels. The square tubes are there to hold the c-channel in place and the triangular plates hold the square tubes in place. You can see how the frame would go together pretty quickly and how a frame with different dimensions would be straight forward. Alternatively, the crossmembers could be replaced with slightly thinner c-channels, but that would add an entire new category of piece that has to be accounted for. Doing it with different lengths of the same square tube seems like better economies of scale. Or maybe doing it that way just won't be rigid enough. Maybe the crossmembers could be the same c-channels as the sides just overlapping inside and outside instead of all inside. I dunno. Seems like the sort of conversation that would be worth having before too many new machines are build with different techniques.Attachments

modular frame releveled.jpg 742K -

I like the concept Matt. I'll likely be trying to employ something like this with the LifeCat (LifeTrac spin off :)Only problem with C-Channels is that those inside flange edges are actually angled (http://www.speedymetals.com/Images/Diagrams/SSChannel.png), so bolting through them is not a good idea mechanically speaking. You can however achieve a similar shape with two piece of angle iron and a flat!Keep up the good work!- Mike

-

I was thinking more along the lines of making our own c-channel, rather than using structural c-channel. Like this http://www.pgadams.com/truckframes.php

Making c-channel out of sheet would ensure we could use whatever dimensions we wanted. I don't think it would be all that hard to build a little rolling mill to bend a long strip of steel into a c-channel. A rolling mill is on the GVCS list right now anyway. Cold forming existing metal, rather than hot forming something out of the furnace, would be a good proof of concept. The system should be tested on smaller/lighter vehicles/machines anyway, so I don't think the steel would need to be thicker than 1/8" based on what car and truck frames seem to be made out of.

-

For the generic vehicle frame, the cross members have to be hot press riveted or specially button welded.

Bolted just won't work

* Shake and rattle will work them loose

* Frame will twist and bend as the small gaps between bolt and hole allow movement

* It won't be certifiable as a safe vehicle in many jurisdictions

* Too easy for varying production errors to creep up the vehicle in poor alignment

* Susceptible to failure when people use the wrong bolts, to the wrong torque

* Bolting doesn't allow the reliable use of light gauge members, as the stress loads are too high in too small a surface area.

And they'll need web flanges at each end too, to prevent racking.

High tensile steel is essential for structural integrity, fuel efficiency, long life, crash crumple performance and light tare weight, which rules out scrap-sourcing the material, which is mostly mild steel.

It's not hard for no reason. It's hard because it's complex and exacting. Hand building a machine from scrap in a farm workshop is only going to produce a relatively heavy machine, requiring regular maintenance. Good enough, but never great. Cheap but time consuming. Unreliable but easily fixed. Slow and heavy, but at least you've got one. So you trade lower capital cost for more time. It still uses the same, if not more, natural steel resource. Overall is it less burden on the planet's scarce resources?

The key to overcoming these limitations is absolute finesse in design, and the ability to trade. So we're at the design stage now, how can we source and apply the incredible knowledge available and required to make the right machine? That's why machinery manufacturers R&D departments are so large. They have to be, to create useable machinery. If it's not good enough, or as good as a competitors, people won't buy it. Likewise in open source software, if it's not good enough, people won't use it. Many open source software projects have withered because a superior product has emerged, usually through the brilliance and perseverance of it's new designer. With open source price is no barrier, so people always tend to using the most superior product.

FeF is a fantasic effort. However they've dived in the deep end with making and building well before designs are complete or thorough. That's fine for in-the-field research and practical experimentation and learning, but it doesn't scale well, and it won't help less well resourced communities use their finite and scarce resources effectively. We can all collaborate very effectively with forums and wikis, but we're going to need to step this up to a much more complex and sophisticated level of interaction to produce viable designs. Much more in depth material lists - potentially pages of research & reasons & specifications for each item, proper cad drawings in fine detail, stress testable software models of components. But have we got the will, the leadership, the software tools, the capability to do these things? Will it be worth it?

An alternative is the Mad Max approach. Any design we come up with on here will never be substantially complete. Energy prices are set to soar very shortly, so production of any sort of new or standardised materials specific to this project is unlikely. That leaves everyone with the option of using what they can find in scrap, second hand, surplus or even new off the shelf. Build crunk vehicles from what you can find and afford. That could mean every item will be drastically different and adapted from what is available, and where does that lead us? Perhaps the efforts on standards are more important than producing machines. Perhaps an overall design that uses common components to ISO standards would be superior, as LifeTrac's change to standard quick couplers illustrates. Even global manufacturers use this approach, for example the new Cat world truck combines their engines with standard chassis, transmission, axle components from different manufacturers. But then we're back to a long list of new components that as a complete package are unaffordable, even when produced in mass scale factories, with huge environmental subsidies.

So I guess we need to accept our standard of living needs to fall, our machines need to cost a lot less, not just to us individually or as communities, but to the planet as a whole. Those efficient global scale manufacturers could make simple, effective, efficient machines that cost a lot less than current designs. Probably less even than we can make them for in our farm workshops. But will people be willing to use them now, while they can still have better ones? Will they only look at slower, simpler machines when energy becomes unaffordable? Currently only those of us really looking hard at sustainability accept the need for lower impact ways to live. If we choose to use the slow machines to run our farms, our costs of production are higher than the farm down the road, and we in turn have to accept a lower standard of material living, and great exhaustion for our efforts. Perhaps we will survive when they collapse in the coming energy crisis.

Some people will always choose the easy (fossil fuel) option, no matter how high the cost to the planet or other people. We can't prevent them, or regulate them, or reign them in, because their numbers are large, the appeal is high, and they control considerable power and resources. So we will have to endure the collapse with them. Will we better off than them? We can't tell. The scale of the downsizing, and the height of the fall have never been seen on earth before. We don't know the trigger, the mechanism or the timing. Energy crisis, social collapse, war, famine, disease - take your pick. Any date, with 2050 being the latest possible time. We can only confidently predict what goes up must come down, and many of those exponential graphs are getting very steep. So we come back to the Mad Max analogy, a window into a post collapse world. He who has energy has power. So by far the most important aspect of OSE are the means for producing energy, not what you pour the energy into. There will be a vast surplus of idle machines needing liquid transport fuels. Only the most efficient of those will be chosen to use the scarce fuel resource. A hydraulic skid steer LifeTrac certainly won't be one of those. Only the most essential tasks will be done using that energy - crops to market, supplies home again. OSE's efforts in biomass, steam & ethanol producing techniques should assume much more importance to our near future.

Let the planning continue!

-

Sometimes my posts turn into stream of consciousness rambling too...but I go back and rewrite them.Anywho...airplanes shake and rattle a lot and they are held together with bolts. Using safety wire totally eliminates the possibility of the bolt backing out. It's cheap and ubiquitous. Kind of a pain, but it's nothing compared to cutting and welding. By definition, a modular system has to use removable fasteners.Modularity always comes at the cost of increased size and weight. That's just the way it is. It's not a design flaw, it's a compromise.As long as the resulting machine includes adjustment points production/assembly errors can be accounted for.A big part of the reason open source solutions aren't MORE popular is the total lack of any kid of warranty. Most people aren't comfortable with that. However, it's largely irrelevant to OSE's mission. Nothing about agricultural/industrial machinery is ever going to be safe or totally reliable. You are always going to be able to build a business around guaranteeing some level of performance for the customer and some amount of post-sale service. The reason open source will work better is that the barriers to entry for the guy building that business are so much lower. Not only is there nothing secret or proprietary about the design, but it's specifically designed to be understandable. They aren't locked in by the design itself or by the knowledge behind the design. Total freedom (as in speech, not beer) means reduced costs for everyone involved.Besides, ALL designs are "susceptible to failure when someone uses the wrong bolts to the wrong torque." That doesn't make open source unique.There is no hope that any of the GVCS machines are going to use "light gauge" anything. They're all going to be over built. They have to be. Maybe, in a half-dozen years, some engineer will donate 3 months of professional CAE and prune a design down to just the bare amount of metal necessary...but his magnificently trim design is still going to get built out of stock angle iron. Besides, when has any piece of agricultural/industrial machinery ever been made out of "light gauge" metal? Even the ones that are already professionally engineered are made out of inch-thick slabs of steel.As for the efficiency thing, the GVCS approach will (I predict) more than make up for the inefficiencies of its machines by the efficiency it creates. Nearly everything the "farmer" needs will be "grown" on site. Including their fuel. The lack of engineered efficiency in the machines and the BTU-chain will be offset by the efficiency of saving time, material and attention. A modular tractor means not having to fix a blown engine gasket in the field. It means pulling the power cube off, tossing another one on, and getting back to work...then fixing the broken power cube back in a workshop whenever you get around to it. That means the tractor stays down for an hour, instead of a day. A modular truck means not having to buy two trucks. It means pushing off the flat bed and loading a crane in its place. That means you never have an expensive vehicle sitting idle. A modular machine shop means the few non-stock components on the machines can be fabbed on location the same day. Or, at worst, fabbed by another farm a few miles away, which means you never have to talk to a guy in China and wait for the part to be shipped. Most importantly, a modular SYSTEM means not having to own a library of product manuals. It means what you learn on one machine directly translates to most of the other machines.That's the power of this idea. It won't make people rich; instead it will reduce their need for money. It will shorten the chain between raw materials and useful products. Not just in terms of what you need to own, but in terms of what you need to understand.Making the system work as a whole requires thinking differently. There's no room for obsessively perfecting a single design. Yes, a frame works better when it's welded. No, you can't ever take it apart again.

-

I recently came across this neat little bit of bootstrapping on youtube and thought it was perfect for this forum thread. It is very easy to make and you could see how easy it would be to increase the power of this basic setup with other motors.

Micro wood lathe: How to make it with a sewing machine motor

Also, this could be a really inexpensive lathe for wax prototyping of tubes, rings etc...

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Allen15 January 2012

- Danial February 2012

- danielravennest January 2012

- DaveMc January 2012

- Matt_Maier January 2012

- Mike_Apostol January 2012

- mjn January 2012

- UtopianPragmatist January 2012

Tagged

- bootstrapping 2

- getting 1

- started 1

- toolbuilding 1