Visit the forum instructions to learn how to post to the forum, enable email notifications, subscribe to a category to receive emails when there are new discussions (like a mailing list), bookmark discussions and to see other tips to get the most out of our forum!

Rocket stove

-

I have been working on a rocket stove these past couple weeks. I am on version 2, and will start on version 3 today.My goal is to make a rocket stove that costs less than US$15 materials to manufacture, and uses no welding.Version one went thru many mofifications to get the best performance. Version 2 is about getting the aesthetics, fit and finish, and materials sorted out. Version 3 will be getting the manufacturing process sorted out.Attachments

144.JPG 29K 139.JPG 21K 135.JPG 30K 128.JPG 28K -

35 Comments sorted by

-

Cool. I'm a big fan of self-imposed limitations like "no welding." It makes for a more interesting problem and, if you solve it, a much more useful product.

-

Today, I spent the whole day on the stove project. After purchasing steel, I wasted a hour driving around looking for a machine shop that had a bender for the metal plate used in the stove. Finally giving up, I went back to my shop, fired up the CNC plasma and cut enough for 9 stoves. I don't have a shears, so I wasted material for 2 stoves cause I had to cut the metal into 24 x48 inch pieces by hand with the angle grinder and cut off wheel. Burned thru a 10 pack of the harbor freight brand cut off wheels on this.

After firing up the machine, I only had 2 bad cuts, both due to operator error. I am still learning the machine. However I did do quite a lot of cutting. Had the air conditioner in the shop on cause it was so hot and humid today.

Afternoon, I headed over to my stainless supplier. They referred me to one shop, but they were rather insulting at the high price they asked and they did not have the equipment to do the job which made me suspect that they would have subbed out the job. They also told me they would maybe have the job done by Saturday.

After leaving empty handed from that place, got a text message to call someone else. He did not have the right equipment but referred me to a shop that did.

I found the place and was pleasantly surprised. They did not have any CNC but they had all the right equipment, and MIG welders. The shop does a lot of fabrication of parts for the rice mills here.

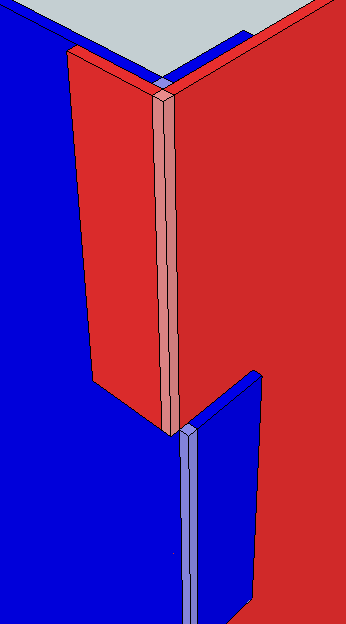

I discovered that my initial design on CNC that I also mocked up on paper was not physically possible to manufacture. I was close though. The material had to be sheared and welded together after bending, due to being a complex part.

The firebox and flue was cut in 2 parts and it took 5 bends per stove. I also had the shop weld the parts together, as they have a much better welding machine. It took 3 hours to do 9 stoves flue and firebox. I am getting better at making these as previous attempts took 2 days to make 3 stoves.

Have one demo tomorrow, one demo Friday and one on Sunday of the rocket stove.

This design for sure is more durable and better than the stove-tec design on the market now. The addition of a "carburetor" on the bottom of the firebox introduces turbulence, and better air flow. Turbulence promotes more complete combustion.

The carburetor design is far from finished however. I am experimenting with different shaped holes and so far have found that star shaped holes work the best.

Tomorrow I add on the heat shield, base, insulation and pot holder to version 3 of my stoves. Kind of excited to see how it will work with the changes.

-

I might add, the way I have come up to make the stove this time is half the cost of purchasing square tube, sawing it and welding it together at the 45 degree angle needed. Over half the materials cost and I am using 1/8 inch steel plate inside the stove. No worries about this one burning out for awhile.

-

I have had a very busy last 24 hours with the rocket stove. Yesterday I drove to a town north of me about 100 miles to do demonstrations of the stove.

We fired up the stove all over town showing everybody from the mayor, small business people, to the local micro finance/ micro industry people.

The stoves got the heaviest use yet with one stove heated up well beyond what it should have by being over fueled. Good news is that the stove lasted even the abuse thrown at it by people who never seen a rocket stove before.

I have been working on the business model for this project, war gaming scenarios. I am split now into 2 business models.

One is I sell the scarcity by using the CNC to make the precision cut parts and work

To establish micro manufacturing franchise/co-op businesses. The businesses will be financed where needed and supported thru the livelihood programs and micro finance (related to Kiva)

The other is establishing dealers and wholesaling.

My first distributor is very interested in the OSE philosophy. He is a community organizer (real organizing not political rabble rousing) and has a organic demonstration farm. He works with the affordable housing efforts and several other related groups.

Version 3 torture tests in real world conditions have shown a few shortcomings of the current design which will be fixed in version 4.

I took lots of video this week and interviewed someone who cooks exclusive with wood. They spend a hour a day gathering firewood and 3 hours cooking on a open fire.

Video will be edited and uploaded to YouTube soon.

Tomorrow another community meeting, delivery of 3 stoves, and demonstration of the stove. -

The Sunday Community meeting was a bust. 2 people took delivery of stoves, one customer was MIA. My demo place turned out to be a area with a lot of crystal meth users.

My trip to the countryside is starting to bear fruit. 2 pieces of version 3 were sold, and 4 pieces of version 4 are ordered.

I also sold 2 more to a American who will send them to his farm here

My distributors are providing valuable testing of the demo stoves I left behind. Yesterday they ran one stove for 5 hours straight, no smoke. The interior flue was glowing cherry red, no smoke no matter how hard they tried to gag the stove with too much fuel.

This is providing valuable info to build the GVCS oven when the time comes. Some requests for a rocket stove powered oven coming in.

Version 4 will have the following improvements:

1 larger legs, the 10x10 inch square of plate steel will go away.

2 change to a gas stove style pot holder. The current version works very well, but it looks too alien

3 change the outer heat shield to heavier metal, flanged and welded to the stove body. Current version is held in place by friction and rivets. Easily dented, heat makes it expand and loosen.

4 carrying handle like a bucket handle

5 upscale model, one with a stainless steel outer jacket.

-

yea, smokeless wood cook stove. Gas is getting expensive here, and if there are supply disruptions then there is no gas at all.

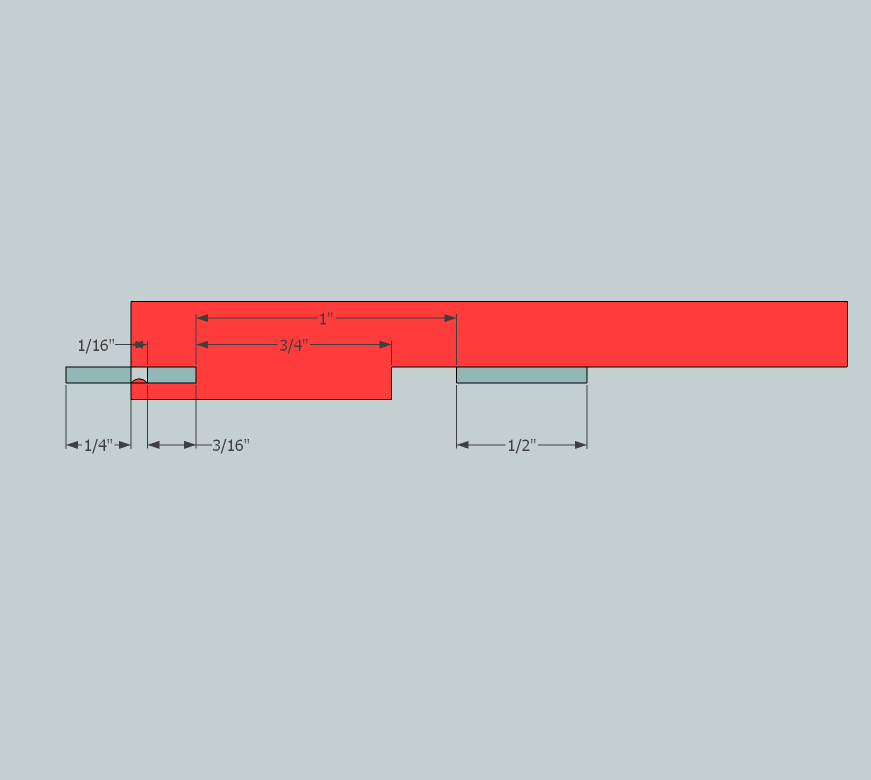

Here is my idea to make the stove without using a metal bender,

-

Cool. I like that you're staying committed to documenting your work.Is there a reason you can't just use a square tube for that part instead of folding a flat sheet into a square tube?

-

what ever the reason, its sweet that he can leverage his torch tool to perhaps make a tube, which in turn keeps the number of unique parts down.

i sent chris whos working on the ose torch table that bent part vid. would be neat to see something similar used to make the table itself. mostly out of sheet metal except for the mechanics.

maybe we could do a bit of a reprap model where new parts are cut and replace old ones kinda deal. -

I checked the prices for square tubing here and it was almost double the price of using flat plate. Believe me I am trying all sorts of things to bring down the number of manufacturing steps and costs without losing quality.

Last night, I made a new carburetor design for the stove that uses less steel and fits better. I tried it out on the stainless stove pictured above. The stove really took off, and the heat was so intense that the carburetor glowed red hot, and the tips of the pot holder even started to glow a faint red. With my previous design, it was hit and miss with performance. I would get a batch to work perfect, and then the next one, not so much.

I may have to make the carburetor from stainless steel to keep it from burning out. it is not much material, only 3.75x11 inch rectangle with holes and 2 bends. However stainless is a pain to cut on the CNC plasma because of the excess dross and slag. I could eliminate it with using a inert bottle gas, but for now the costs are not worth it.

Saturday comes the biggest demonstration yet. 300 people are scheduled to attend. Latest batch of 10 was sold out pretty fast.

For the pot holder, I will have to stick to the gas stove pattern. Anything else looks too alien and people are leery of cooking on it. I may have to make the pot holder even larger to accommodate the giant woks they use here. I find the use of a wok odd here because they used to use cast iron pots until not long ago. It is now very hard to find cast iron.

-

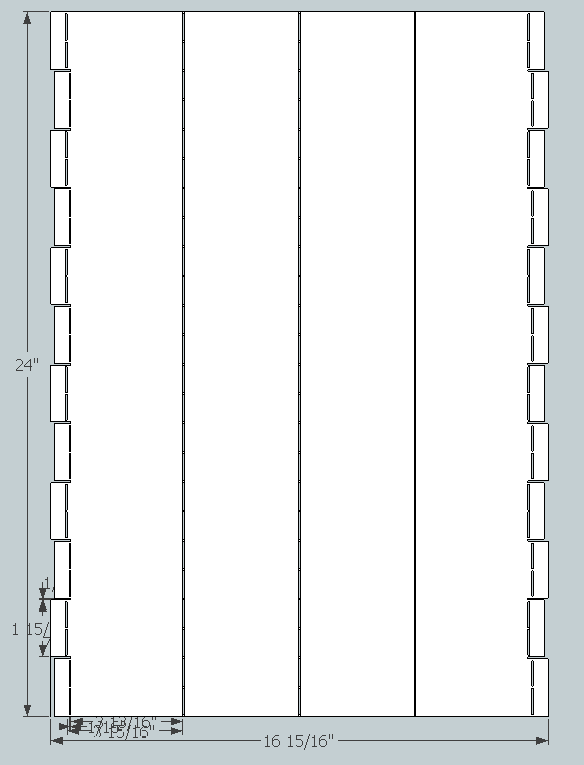

i drew it out a little betteri think drawn as is it might flip side to side a little. maybe a little piece could be bent out on either side to support that?heres the sketchup fileAttachments

metzslideinpotholder2.png 8K -

i had an idea and drew it up. a 4x4x24 tube with a sort of interlocking joining edge.might not work out but just an idea :Dheres the fileAttachments

metzq1.png 8K

metzq2.png 20K -

I tore apart a version 3 stove that was torture tested for a couple weeks. Lots of crud on the inside but very little corrosion. The heat shield looks terrible however.

This one I can rebuild to version 5 pretty easily though. I disassembled 4pieces of v3 stove and they are ready to go to the weld shop tomorrow for new pot holder and new heat shields.

Loold like galvanized is out for the stove. My guy used it to fry chicken for 3 hours and it discolored. I tried BBQ grill paint but it is cheaper to use unpainted stainless, as well that stainless has a higher perceived value.

I am changing the insulation to perlite and eventually a perlite/pumice mix. Fiberglass is too itchy and perlite is $3 less per stove.

The stoves are selling. Have 8 orders in the pipeline. Making 20 pieces this week, setting up the demo stove at the public market on Saturday and selling them. Got one order today when I stopped to get a freight quote and the trucking company owner bought one for his employees use. -

Night time burn with the stove. The flame is higher than usual, this increases heat output. Downside is that when the flame protrudes from the stove, there is increased soot on the pan.

Here is the clean out after a hour of cooking. Next order of business is to weigh the wood burned, weigh the ash and charcoal remaining, and publish the results.

-

Are you familiar with this open hardware stove project: http://www.goodstove.com/

He has done like 50 designs I think.

-

I checked out his site. Interesting but most is info I already read in other places.

Here is a video of my inner flue design. the background is a cut sheet but not bent, It is 3 bends on the big machine, then a hand bend and weld. I am down to 6 bends per stove. As I pay per bend I need to keep the numbers down. I also pay by the number of welds so this stove has half the welding of previous models.

Outer heat shield will be square. It is easier to bend than roll for fabrication.

I reduced the number of prongs on the pot holder to 4 instead of 6. I made the prongs larger though and angled to support anything from a small fry pan to a giant wok.

Yesterday I did 2 demos. I accidentally dropped my stove clean out tool inside the stove. The tool got bright orange and got so soft it started to warp. I am finding a layer of slag on the sides of the stove after a long hot burn. I wonder how this will affect the stoves lifespan. I am guessing a minimum of a year right now. The stove now weighs 20 pounds with the fiberglass insulation.

-

I have uploaded a preliminary blueprint to the open source rocket stove design here.

I had put off the documentation for awhile with everything else in the shop keeping me busy.

Anyways yesterday I had to fill a order for a rocket stove and found that my own documentation was lacking. I had to re-create some files to cut out on the CNC. I put all the drawings in one file and am writing up the build instructions today.

Yesterdays stove was the first full stainless steel design. I was short of 2mm steel plate in the shop and had a half sheet of 1.5mm mirror finish stainless so I used that. I also changed the insulation from rockwool fiberglass to woven fiberglass like the type used in boat construction. I used a kilo of it in the stove and the cost was about 3USD. It is much easier to wrk with than the itchy house insulation.

We delivered the stove to our customer and fired it up as a demo to make sure it worked for them. The all stainless design worked really well. The only concern was that the pot holder got so hot that it started to glow cherry red. We boiled 2 full one gallon tea kettles on it with only a small handful of dry hardwood sticks.

Attachments

OSRL rocket stove.pdf 726K -

Thanks Metz. Did you use regular fiberglass or high-temperature mineral fiber? I know for home-insulation style fiber, rock-wool fiber which can go up to 2000 degrees should be used, not regular fiberglass.

Also, how did you determine the optimal dimensions of the size of the cross-section of the flue, length of the feed, and the length of the heat-riser?

How long does it take to get up to temperature until it has smokeless operation?

-

If I jump start the ignition with a squirt of denatured alcohol it now makes no smoke if I use dry wood. It is ready to start cooking within a minute or 2 now. I am using fiberglass cloth now instead of the household insulation. The household stuff is expensive, takes a hour drive to buy and is hard to work with. The fiberglass cloth is half the price and a 3 minute walk from the shop.

Made another stove today. I am going to change the pot holder design again. The current design is pretty cool and all but I have a big bar of 1x1/4 inch stainless going unused so I will be using that tomorrow in the shape of a X.

The documentation is coming along. Lots of photos and video to get organized and put in the proper format. It hopefully will be up on the OSRLiving wiki within a week or 2.

. -

I kind of abandoned the rocket stove for awhile. The last design took way too much welding to make and was not economical

Y viable.

I restarted the project a couple weeks ago after getting a call from someone wanting stoves by the thousands. He has 40,000 hectares of elephant grass to convert into biofuel pellets.

So back to the drawing board. I spent a ton of time worki g on the TLUD gasifier. Turns out pellets really only work reliably with forced air. I did come up with a good design that will also gasify wood chips.

Customer did not want any fan so back to the drawing board.

I have now come up with a hybrid gasifier/rocket stove. Overload the stove with fuel and it gasifies, it solves several of my issues with ease of use in the stoves. This stove is much more forgiving with the fuel feeding.

Only thing is I am still trying to figure out how to make it economical. The stove requires some precision cut elbows. Right now I am using the CNC to cut flat sheet and roll it. However for mass production, it really needs to be made from tubing cut on a bandsaw or power hack saw. -

I saw one of the version 2 stoves a couple weeks ago. The one made from the cheap steel. It burned out with a large hole in the side. The stainless stove aside from discoloration worked like new. It has been in continuous operation since June of last year.

The shop that I was using for fabrication of my stoves last year, has moved, into my building. I am doing CNC plasma work for them, and they let me use their bender and pipe roller. We are collaborating now on the mass production stove design. We have some good designs, but we need to I crease the quality as well as keep the cost below 12 dollars wholesale. -

The rocket stove design I have gone as far as I can. Issues like long burn times and ease of use, caused me to go to the TlUD gasifier design with forced air.

I switched back to ordinary steel and a phosphate coating due to price costs.

The last TLUD design I sold had blue flame, and 2 hour operation on one load of fuel at $100US per unit.

Gasifier seems the way to go after 2 years of experimentation -

It is for people to cook using local materials instead of using gas or charcoal. Many things in the current GVCS are not practical in the very countries this project is purported to help. I'm in a place where I can go from Beverly Hills Splendor to Bangladesh squalor in the space of 5km. People here are cooking with wood and using 3 stones to support the pot which makes a incredibly polluting smoky fire.

Just within the last 6 months have rocket stoves been on the market here.

Propane Gas is not universally available or it is hugely expensive. -

I've been working on a batch burning rocket stove design that uses woodchip (or could use smaller sticks or other similar biomass) for the insulation that is turned to biochar.

http://www.appropedia.org/Forest_biochar_rocket_stove

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

Loading