-

Hi everyone,

I am a textile engineer and I am working for a french local and ecological clothing brand. We are developing an open source technology for dyeing clothes with recycled materials such as avocado rinds, onion skins, carrot tops, flowershop wastes, tea and coffee wastes and, eventually, local plants.

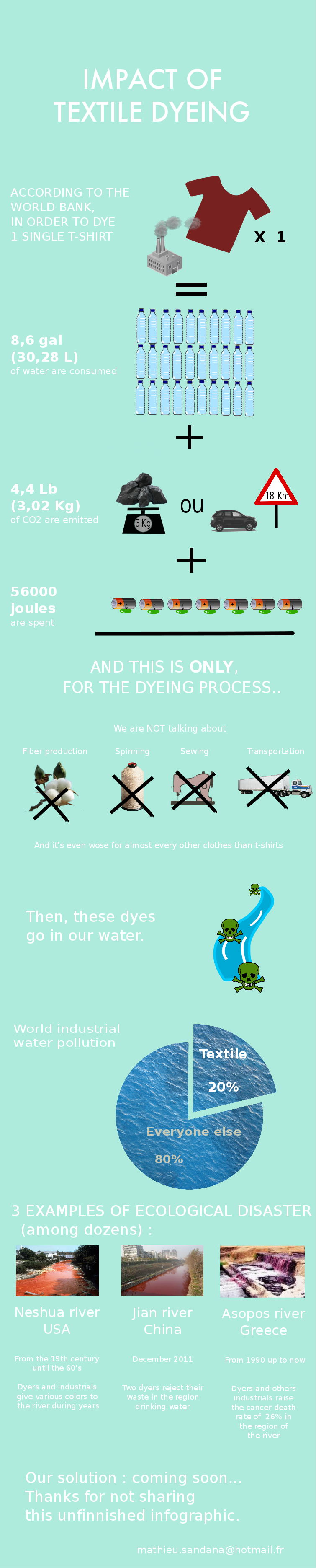

The environnemental impact of textile dye is pretty huge. If you want, you can check this infographic I am working on right now (based on world banks data) here.

We are now recycling organic materials from local business and reusing our dye bath and dye wastes for composting. We are currently doing this by hand-craft at a very small scale. But in order to do this faster and easier, and to help industry and textile workers to dye with local materials without spending too much energy, water and money I want to create a new ecological dyeing machine :The machine i want to create should allow us to :-Deep in organic dye material (coffee, flower...) and extract dye by agitation (slow or fast) and heating (up to 80°)-Get rid of solids remaining with a simple filter so only the liquid dye remains in the Vat.-The cloth can be dyed for a long time (during days, at room temperature and with a slow agitation of the bath) or for a litlle time (up to 30 minutes, with temperature up 80° and with slow agitation of the bath too).-Deep in cloth or textiles in the slowly moving dye bath and eventually hot dye bath (for cold and long dyeing-To drain the dye bath in order to use it again laterHere is a 3D Video of the machine : http://youtu.be/3BQ38YBOyuI

In the video the size of the machine is actually exaggerated (compared to the clothes) it should be around two times more little

The solution I thought consist of is using :

-An inox vat with a simple valve for draining (We'll buy wine production vat for this),

-A mechanical agitator with a motor fixed to the VAT cap and plastic (?) blade (or another material that would not not damage the cloth.

-An heating ringWhat do you think about this solution?

As a textile engineer I lack knowledge in mechanics and classic engineering, so any piece of advice or useful links would be very welcome. Unfortunately, I didn't find much help offline and I am working alone on this project.If you can think on a faster, better and cheaper alternative than the one I thought of, let me know ;)

I also don't know yet, how to assemble the different componnents together, especially the motor and the vat top. And there might be other issues I haven't tought of yet.

We will promote this project through kickstarter soon (the cost should be around 1200€/1500$.)

Dyeing cloth might seem minor compared to other technologies regarding resiliency/neo-subsistence but from this machine we could work easily on a open source ecological washing machine and help the open source project oswash.org/ and promote local textile industry along with the OSloom project. And there is probably other implications for this machine in the field of chemics.

Mathieu, from Paris.Attachments

infogaaphie english.png 798K -

5 Comments sorted by

-

Brilliant work Mathieu, I've emailed you offline too, but obviously I'll be following this with interest. For anyone else interested in this thread, do go over and subscribe to http://opensourcetextiles.wordpress.com/ where we'll be following the project with some articles. I can't stress enough how important textile technology is. It shaped the very fabric of the industrial revolution, and has been the cause of a huge amount of ecological devastation and social inequality. Stuff like Mathieu's project will help us redesign textile mechanisation to something that is much more human friendly.Craig

-

Thanks Craig :)

I am concerned with simple questions such as : which motor should I buy ? Should I buy a separate turbines and blades ? In what materials ? and also how I should assemble everything ? Or should i buy directly a a motor + tubine + blade system (slow agitator) ?

This machine could be very useful to save and reuse water, which our actual dyeing and washing machine are not made for... -

I can probably get you some advice on that, I have a few engineers I can enlist into helping occasionally. I'm not sure how best to collaborate with you though. I'm familiar with collaborating on open source software projects, but open source hardware projects are much newer to me. To get someone to recommend a motor or something, I think we'd need more information on it's use. I've seen your 3d animation of course, but I don't understand all the requirements on the machine. Perhaps we could get together for a skype chat or something? Drop me an email and we'll figure out a time.

-

Thanks Craig, open source engineering is really new to me as well :)

I did forget to give some specifications :-It should be a slow rotation agitator : between 20 and 30 half rotation (going back and forth) per minute.-It should not damage textiles (so a plastic blades would be good).

-The sharper material in the VAT would be avocado rinds and cloth buttons.

-The total mass of textiles in the VAT would be around 15-20 kg (33-44lb).

-The volume of the bath should be between 200 and 300 liter (52 - 80 Gallons).

-The draining system doesn't have to be extremely complicated, gravity should be a sufficient force for it, it's just supposed to help us reusing the dye bath and cleaning the Vat, as the colth will go through a classic whasing and drying machine afterward.

-The vat has to be in inox for avoiding reaction with the dye bath.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- craigambrose June 2012

- MathieuRaj June 2012