-

I sent Marcin a proposal on Feb 12, to build a prototype

Open Source Automobile before the end on 2012, but the proposal needs some

fleshing out, and soon. To quote my proposal, “…the first and most critical

task is determination of specifications. We have about two weeks of February

left, which is sufficient for this phase if we apply ourselves.” But that time

is about half gone, so I’d like to open the question up to the forum. I

understand this was discussed at length a year or so ago, but apparently the

notes were lost/purged so we need to start afresh.Let’s start with the start: from the OSE’s

Car/Research_Development wiki page:>>>The basic requirements for the OS Car are: Two passenger

capacity, Ultra-high fuel economy (50+ MPG, city, 100+ MPG, highway),

Ultra-long range (1000+ miles), Low Cost (less than $12,000), Ease of

Construction (1000 hours of construction time. Can be constructed by one person

in 1000 hours with a vertical mill, band saw, disc sander, grinding wheel, air

compressor, welder)<<<If the specs were simply as defined by the “The basic

requirements for the OS Car are..." paragraph, this would be a walk in the

park, but there’s more to it than that. Other OS Car specifications are

scattered about the wiki, and Mark Norton (who is expediting these negotiations

between Marcin and myself) tells me that Power Cube (and Steam Power Cube when

available) compatibility is essential. Since Marcin will be making the

decisions, I think his requirements should be the core of the specifications

(and only calling for discussion if they conflict with themselves) and we can

build on them by adding features that don’t conflict with the essentials.It seems we have all the specifications we need and the

challenge will be deleting specifications, not adding to them. In choosing

which features we’ll have to choose between those that are incompatible with

each other. I’m picking through the wiki and blog and hope to list all the

requirements therein, in a day or so. Once they’re all posted in one place, we

can blue-pencil out the unnecessary/impossible requirements and present Marcin

with a compilation of what remains.Here’s my interpretation of the requirements currently

established, toned down a tad by Yours Truly:-> Investor- and contributor-acceptable progress in

2012 (Marcin requirement, toned

down by JMcC)Marcin has often stated and written that the GVCS 50 will be

completed in 2012. Despite his many enthusiastic supporters, the funding and

staffing are not yet in place to achieve this, so in practice, I think

“completed” is the hope and “investor- and contributor-acceptable progress” is

the requirement. Pardon the tautology, but the funding sources that don’t find

the progress acceptable won’t fund future efforts at progress. For the car project,

I think the “acceptable progress” minimum is a functional first prototype.-> Compatible with Power Cube and upcoming Steam Power

Cube (Marcin requirement, toned down by JMcC)Acceptable progress doesn’t necessarily mean the first

prototype has to have Power Cube power (or steam power) but it does have to

lead in that direction. The first prototype may not be powered by “…the 75+

miles per gallon, modern-steam, biomass pellet-fueled Power Cube…” but it needs

to have the space to put one when it becomes available.I toned down Marcin’s requirements (above) because, though I

believe [completed in 2012 AND steam power AND power cube] is possible, it

would suck up so much of available resources that the OS Car project would

scuttle most of the other GVCS 49 projects, thus disappointing contributors and

investors and putting the GVCS at risk.The rest of the Car/Research_Development “basic

requirements” aren’t really requirements, but they’re worth considering.->Two passenger capacity.

Sounds good to me. A two seater covers 95% of US culture’s

personal transportation needs; so does a single seater but if it’s going to

have a Power Cube then a second seat won’t add significant frontal area.->Ultra-high fuel economy.

Good idea in my opinion. Without ultra high fuel economy

there’s not much point in doing the OS Car at all. I do think the “ultra-high”

needs to be redefined; I’ve built a “50+ MPG, city, 100+ MPG, highway” car and

it isn’t as easy as it looks, and it may not be practical with a Power Cube.

And 75+ mpg steam? Per gallon of what? Biomass pellets? Steam?->Ultra long range (1000+ miles)

Seems excessive to me. I have a car with a 1000+ mile range,

because it’s multifuel and I use different tanks in testing, but in practice

it’s totally unnecessary. I don’t mind fueling up every two weeks instead of

every month around town, or topping up every day when driving long distances.->Low Cost (less than $12,000)

Essential for my participation under current terms, but

that’s just me. I’ve bid $15000, paid in stages after completion of benchmarks,

that’s material plus $3000 in outside services to substitute for GVCS tools not

yet developed, and that’s all the money I have to risk.->Ease of Construction (1000 hours of construction time…

The tool list doesn’t need to be in the specs, in my

opinion. Also, I’m shooting for 500 hours for the prototype, and subsequent

cars should come easier.

-

41 Comments sorted by

-

What would be the luggage carrying capacity? I can understand a proof of concept two seater with very limited luggage carrying capacity but then, is it practical for family of four use? A motorbike can pretty much do the same, no? What do you think is a practical number for range?P.S: Thanks for creating this thread. I have added to my bookmarks and hope to learn more from you on the subject.

-

I've let the Miata be my guide to luggage capacity, but on my car (MAX) I also made the passenger seat quick remove, so I can carry a healthy load when I need to move stuff but not people.

Sure it's practical for a family of four, for those many times (the majority) when not everybody is going somewhere at once. I'd rather look to the next project (the open source truck) as a platform for big loads, perhaps with rows of removable seats. Some times a big vehicle is the most efficient from a passenger miles standpoint, but in our culture, the problem of fuel efficiency is more often that a big vehicle has one guy in it. A 4000 pound vehicle with a 200 pound payload (the driver) is using 95% of its fuel to get itself around, 5% to move the driver. One thing I favor about the OSE village concept is that the village could have a few special purpose vehicles instead of one vehicle to do everything.

A motorbike can pretty much do the same, but it's not as safe as a car for most people and I've found few motorcycles that get 100+ mpg on the highway. And where do you put the Power Cube?

As far as a practical number for range goes, that depends on how common the fuel is and where you're going, but I think 300 miles is more than enough if fuel comes from a pump, and I once drove a car coast to coast with a 200 mile range and it was no trouble--I want to stretch my legs more often than that when I'm traveling. Even running on biomass fuel pellets I think 300 mile normal range, plus a trailer hitch for a light weight pellet trailer, would be fine.

The only reason extended range has been helpful is, when I'm driving my own high mileage exotic, a fuel stop can take an hour because it draws a crowd. I suspect the first year or so in the OS Car will be similar...you don't want to be rude to those folks, that's where the new recruits come from. :-)

-

It would be good either compile, or find an existing source of, energy density for various fuels and efficiencies for various engines/running gear. That way the discussion of trade-offs can happen fluidly.As you pointed out, OSE hasn't really defined a clear mission for the OS car. At the moment it seems to be just "whatever we can get." Maybe that's best, but it would be nice to set an actual goal.Also...it would help justify working on a passenger car when the core mission is a self-sustaining farm that negates the need to commute.

-

Thanks for your detailed answer Jack :)

Your point about a car using 95% energy to carry itself around reminded me of a similar talk delivered by Amory Lovins of Rocky Mountain Institute. He was advocating use of light weight composites to improve the useful weight carrying percentage. He also made a point about less part counts. Infact RMI had teamed up with a startup fiberforge to create a concept 'Hyper Car'.

http://move.rmi.org/markets-in-motion/case-studies/automotive/hypercar.html

Is there a place for composites in all of this? -

Hello, my first post here.

I would just like to say that the mileage target is somewhat hard to understand for me. Where on Earth people need to travel for 1000 miles non-stop ? If it's intended to be an absolutely low cost solution for, lets say, a farmer getting his goods to the local market or buying some supplies I would go with some really low tech solution with the range being "just enough" (100 miles tops). Wood gas fueled combustion engine, or compressed air maybe ... electric engine would be great, but you won't get even those 100miles with your planned lead acid batteries.

-

> Is there a place for composites in all of this?

I think there is, hafeez, because a few of the body part shapes need to be compound curves and metalworking compound curves is outside of the GVCS capabilities. Simple curves (curves you can cover with a sheet of paper without tearing or crumpling) won't do for the front fenders, for example, because sharp edges in front produce excessive aerodynamic drag and excessive injuries to pedestrians. Hand layup fiberglass composites are probably the easiest path to complex curved parts.

Andy, I agree with you re the mileage target, and I don't know where it came from. My theory is, if the car is powered by something not readily available (e.g. biomass pellets made at home) it may need the range to get where it's going, and back. I had the fun of competing in Escape From Berkeley a few years back in MAX (before it got streamlined, when it was getting 70 mpg), a Berkeley to Vegas over-the-highway race simulating a future with no petroleum fuels and no money. MAX can burn a variety of fuels, and we ran it on cooking oil mooched from the shelves of groceries and convenience stores. I don't think dystopia is going to hit that fast in real life, and we'll be able to call ahead to heating supply stores to get pellet stove fuel if we need to get from, say, Oregon to Missouri on steam power.

> ...you won't get even those 100miles with your planned lead acid batteries.

My only plan for lead acid batteries is one 12v battery to start the engine. There are light and cheap batteries in the big-box stores' garden departments, for use in riding lawn mowers etc. They're the size of small car batteries, but weigh and cost half as much. Motorcycle batteries may be sufficient, and if so they're even lighter (but pricier).

-

I wonder if the GVCS could incorporate some kind of natural composite. Like tree sap and grass. I dunno, some combination of harvestable substances that would act like fiberglass.

-

If I recall the number correctly when Toyota did a while ago some extensive road tests with an electric RAV4 they have came up with 250Wh per km. Even if you would cut that in half (a lot lighter vehicle, better drag coefficient etc. ) you would still need 125Wh per km which is more or less 2.5 kg worth of a typical lead-acid car battery. 100 km = 250 kg of batteries. Obliviously the more you add the harder it gets to make the car lighter.

I know some people who were doing EV conversions and they usually weren't able to get the range over 40-60 km with lead-acid. Just switching to Lithium batteries usually meant at least doubling the range (and more than doubling the costs as well). I think Tesla is going to offer a 300 miles range version of their Model S and that's probably as much as you could dream of with todays technology. No alternative technology I know of would allow a 1000 mile range. There's nothing even close, not to mention we are talking about a DIY approach, so no fuel-cells, hydrogen storage etc.

I would argue that lowering those specs would make a lot of sense and allow for a more flexible approach to design.

-

Regarding a vision statement for the OSE Car. My thought is that the car is for personal transportation exclusively. It should carry one or two people from point A to point B efficiently. If it can carry luggage or a small amount of baggage, so much the better. There is no need to include transportation of bulk goods in the car, we have a truck project for that purpose. From my point of view, the car design has to meet the following criteria:

- Buildable by a person with reasonable skills with access to an equipped workshop in a reasonable amount of time. 1000 hours is a good target.

- Cost to build should be less than an inexpensive new car. Less than $10,000 is a target.

- Meets requirements to operate on public roads and highways. These vary between the US and other countries.

- Is inexpensive to operate. I think 50mpg is a better initial goal that 100mpg - we can make it better later.

- Has a reasonable operating range. 500 miles seems more realistic to me.

- Follows OSE core values for modularity, repairability, modifiable, good documentation, etc.

Marcin doesn't completely agree with me on this last point. This is what he had to say on the matter:

I'm all for creative solutions and I do think that our society does stifle innovation on behalf of those that lobby the most, but it's just not practical to have a car that we are not allowed to drive. If we are going to produce a car that can be used in public based on regulations that will exist for the foreseeable future, we"ll need to add design criteria for:I also need to emphasize that our approach is non-religious and

non-political. As such, I do not endorse any politicized or religious

regulations that are contrary to sound ecological and technological,

safe design. This means that we build the car on technical merit and

safety and ecological performance - not existing regulations. This is

consistent with the base OSE principle of an absolutely creative approach

for delivering fundamental and lasting solutions - as opposed to

reducing ourselves to mediocrity and dependence as enforced by current

commercial law.- Impact safety including a good frame, seat belts, bumpers, etc.

- Operating requirements such as signal lights, head lights, running lights, brake lights, etc.

- Emission requirements - this is good for our planet, too.

- Speed - must be capable of minimum road speeds for highway operation.

- Reverse - pretty much a requirement to park it in a public place.

- Mark

-

There is another reason to refine our criteria for an OSE Car design. Recently, a number of qualified people have expressed a desire to participate and/or lead the development of an open source automobile effort for OSE. Specifically Jack McCornack's Kinentic Aerospace group and Joe Justice's WikiSpeed group. Both have designed and built high efficiency cars in the past couple of years and as such are qualified to help us design an open source car. There are also others who seem qualified and have expressed interest last year. Finally, there are efforts outside of OSE to do pretty much the same thing, such as the OSCAR project.

The question before us is how we will proceed. In the past, OSE has looked for qualified subject matter experts and retained them to develop a design to OSE criteria. In some cases, those criteria have been loosely established leading to misunderstanding among those involved. As such, it is essential that OSE - as an organization - have a clear understanding of what it wants in an open source car design.

There are (I believe) two main approaches to going forward: a competing design effort or a cooperative design effort. A competing design approach could led to a strong design and allow the selected team to manage the project in their own way with their own people. However, there is waste of time, effort, and possibility money. A cooperative design approach leverages a larger group of people (more ideas, more hands on the task, etc.). While there may still be waste, overall it is a more efficient process - if it is well led. Therein lies a possible problem, since Joe will advocate strongly for his Agile/SCRUM approach. That's fine as long as the whole team is willing to work using those methods, but I suspect that we have two powerful leaders who may be unwilling to share responsibility or work for the other. That's to be determined>

Marcin has asked me to help sort this out. I am in contact with both teams and hope to resolve some of these issues over the next few weeks. We'll need to move quickly if we want to stay within the scope of completing initial drafts of the GVCS-50 this years. While I'm not concerned with all 50, it would be nice to have the OSE Car design in place and prototyped by the end of this year.

- Mark Norton

-

> I wonder if the GVCS could incorporate some kind of natural composite.

Super Sap Epoxy http://www.entropyresins.com/

Andy, while new battery and electrical generation technologies are in the GVCS works, the first OS Car is going to be guided by Power Cube compatibility, which is internal combustion. I don't think this is a horse that'll be changed in mid stream--we need prototype #1 finished in ten months and a week.

Re the vision statement, I'm with Mark in concept. If the prototype is not "street legal" there will be a lot of unnecessary difficulty in long term testing and public demonstration. This is not a car show car, it's a step along the way to a practical vehicle. One good way to assure it's street legal is to register it and license it. Though every state has its own Vehicle Code, they all subscribe to common minimum standards such as light requirements and windshield material requirements. In practice, if a car is legal for road use in one state (which includes license, registration, and insurnce) it's acceptable for road use in the other 49.

Mark, I personally consider $10,000 a good target--it's what I used for the MAX budget--and really any figure can be used. by adding/subtracting features; Marcin's original specs said $12k and he's going to be the decider, so that's what I went with. However, in my latest research on hydraulic drive, it may need to be $12k because to beat 50% drive efficiency will call for sophisticated (ka-CHING) pumps and motors. And could you ask Joe Justice to hop into this discussion? He's another guy who can speak from experience.

-

As for the price tag I wonder if $10k would make it a game changer and the question is who do you expect will want to build it? Tata Nano for example costs around $3-4k and more or less meats your criteria (maybe except the 500 mile range - still can't understand who needs this on a daily basis). For various reasons in EU and US it will be twice as expensive but still cheaper than the 10,000 dollars you're planning.

Nano is also worth looking at as far as lowering costs. They've managed to find some really clever ways to cut on materials and/or labor.

-

I have collected various criteria from the wiki and this forum and posted them to a new wiki page at http://opensourceecology.org/wiki/Car/Design_Criteria

This is a draft and is open to discussion and improvement.

- Mark

-

"No alternative technology I know of would allow a 1000 mile range."

>> Maybe aluminum air batteries.

I totally agree with the "it must be street legal" requirement. Otherwise what's the point? It will be modular anyway, so if a person wants to build it NON-street-legal they can do that by simply not purchasing or installing certain components.

So, we can probably get started on the BOM by sourcing the required system. Things like air bags, restraints, ABS brakes, sound systems, parking brakes, etc are reasonably standardized. The prices and specs should be researchable. Taht will give us teh "mandatory spending" portion of the budget and whatever is left over we can use for the interesting things like frame and engine.

Where does the absurdly high mileage requirement keep coming from?

I predict that we are going to have to design a new power cube for this application. A guy at hydraulic innovations who converted his car ran into a big problem of not enough flow to reach highway speeds. Wikispeed says their vehicle requires 50hp. I just don't think the 30gpm, 25hp unit we have now is going to cut it. Additionally, we're going to have to design an entire hybrid hydraulic transmission anyway. We'll need a big accumulator, and complex manifolds, and it all has to be light and modular. Given the challenges, I think the difficulty of specing out a new engine/pump combo and sticking it inside a frame is acceptable.

Additionally, I think we need to decide up-front who the target fabricator is going to be. I suggest we completely abandon any fantasy about this being a person's first project, or it being done by an experienced amature. I think the only practical fabricator is going to be someone who builds things (hopefully cars) for a living. Additionally, we should seriously consider designing the car to be manufactured in pieces by specialized shops and then assembled later. It will be modular anyway.

-

Mark, that's great, that wiki page is going to be quite a help. I dove in and started its associated Discussion page, with a suggestion that we not try to make OSE villages the car manufacturer. If these cars are built a la the US (and UK) kit car industry and the owner does the finishing touches, the cars will not have to meet Federal standards for series manufactured automobiles, which are quite stringent, and in many ways excessive.

> So, we can probably get started on the BOM by sourcing the required

system. Things like air bags, restraints, ABS brakes, sound systems,

parking brakes, etc are reasonably standardized. The prices and specs

should be researchable.

Not all that standard, and spectacularly expensive in modest quantities, and let's not forget Electronic Stability Control, mandatory on all series produced automobiles in the US, starting this year.. The nanny-state thing re automobile safety gets full support from the established manufacturers because it creates an entry barrier to new competition, and it keeps costs (and thus earnings) high per car. Why don't racing cars have airbags? Seat belts debuted in race cars, as did rear view mirrors, but auto racers wear harnesses that restrain the driver's body in an accident (as do I and my passengers in MAX--it comes over the back of the seat and over both shoulders) so airbags are moot in auto racing. Air bags are mandatory in mass-produced road cars because the regulators determined that "passive restraints" were required and US car buyers don't like being forced to wear a seat and chest belt. Sure, it's the law, but so is 35 in a residential zone.

Martin wrote, "This means that we build the car on technical merit and safety and ecological performance - not existing regulations" and I'm with him on this one (note that despite my eloquence when I disagree, I see eye to eye with Marcin on most things). There are a lot of regs we can skirt without violating the law.

> Tata Nano for example costs around $3-4k and more or less meats your criteria

It does, more or less, but it doesn't meet US series manufactured automobile regulations. Tata makes millions of cars, and can't use the small production rules to get around the mass production regs.

-

I've added a way too detailed and documented explanation of why (IMO) Power Cube propulsion is unsuited to the OS Car project.

There are ways around the worst of the problems, but they're not total solutions and they appear to be pretty pricy. I have RFQs in to variable displacement hydraulic pump manufacturers, but other than Honda I haven't had any leads in the Power Cube range of performance. Most of the pump manufacturers want to make them for earth movers, and Honda thinks I should be buying them with ATVs attached. I'll keep you posted, but for delivery in 2012, I think a car-dedicated power source is the best way to go.

http://opensourceecology.org/wiki/Talk:Car/Kinentic_Vehicles_Proposal

-

I responded on the discussion page. Basically, I agree the power cube won't work for a car. My suggestion was using Wikispeed's engine/transmission unit, putting it between the front wheels, putting two people behind that, and sticking a dragger wheel on the back. We'd get a 2-seater 3-wheel modular vehicle with as much drivetrain efficiency as it's possible to get without hub motors.

-

It should be pretty easy to adapt WikiSpeed's engine/transmission unit to front wheel drive, since that's where Honda had it originally. You could save design time by leaving it exactly the way Honda did it; you'd lose Wikispeed's ability to do hyperquick engine changes ("...in the time it takes to change a tire") but engines don't need to be removed and replaced very often, and even if an engine swap takes all morning it's not a serious weakness.

I think a smaller engine would be better for the OS Car. This first prototype is a step on the road to a steam and/or powercube car, which will be considerably less powerful than the engine in the Wikispeed. OS Car marketing will be driven by very different forces than WikiSpeed marketing (from wikispeed.com, "Current iteration tests 0-60 in 5.5 seconds, top speed of 149 MPH") and the OS Car doesn't need that sort of performance, and so doesn't need that kind of horsepower.

My recommendation to Marcin back in 2010 was to use a Geo Metro engine/transmission unit for the first prototype, and leave room for conversion to Power Cube later. Frankly, I think a Metro engine would be an excellent Power Cube engine; they're plentiful and cheap, and they're more fuel efficient and less polluting than the current Power Cube engine. Part of the point of the Power Cube is it can be adapted to different engines, and this is an engine worth considering.

-

I've added my observations (and conclusion) re why I think four wheels is better than three for this prototype OS Car to the http://opensourceecology.org/wiki/Talk:Car/Design_Criteria discussion page. It's almost a thousand words long, so get some coffee first before you click the link.

-

First reactions: I too think the range of standard cars is plenty. Reducing our total mileage is a popular trend. OTOH, I think the MPG goal is rather low. How about trying for 50% payload capacity? That's common on big trucks, and easily beaten by a motorized velomobile. Unless we can easily produce our own highly efficient hydraulics, I'd stick with mechanical power transmission. Modules are very tough on space utilization. If there is space for a power cube, it should be shared with luggage area, so it can be usefully recovered if someone buys a dedicated engine.

I'm fresh from 3 weeks at WIKISPEED, and think they have some good management tools, but are too locked in with the frame design that passed crash testing, but has no doors or roof. Retaining parts of it limits develoment severely. I draw the hardest to change parts first. Ground plane, people, wheels, and engine placement define the character. Other parts get tucked around those, and then a frame connects the dots.

-

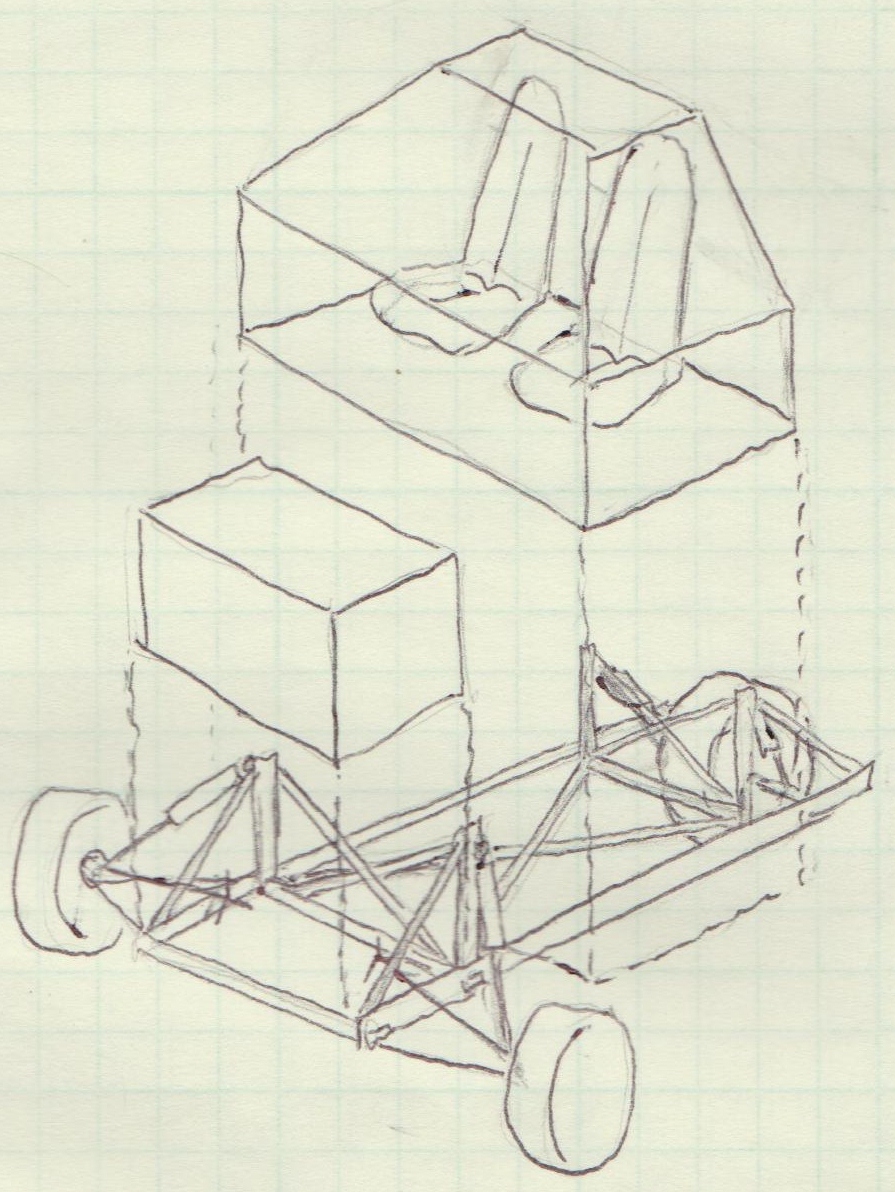

LOL, yeah, I've been fighting with that frame on my sketch pad for a couple weeks. I can't figure out any way to make it work as a practical vehicle without changing the frame at least a little bit.I'm picturing the OS car being a 3-wheel, 2-person tadpole. Wikispeed engine unit driving the two front wheels. A reasonably standard c-channel box frame (maybe with some space frame elements) that everything attaches to. A passenger cab unit that bolts on to that. Done. The only thing that needs to be safe and comfortable is the passenger cab. Just throw one or more polycarbonate shells over it for streamlining.Attachments

OS car sketch.jpg 482K -

Bob, I agree with every point except the one I don't understand - by 50% payload do you mean two 175 lb people in a 350 lb car?

From Matt...

> My suggestion was using Wikispeed's engine/transmission unit...

(and in a later post)

> Wikispeed engine unit driving the two front wheels...

Matt, what am I (and perhaps others) missing here? What are the features of the Wikispeed engine and transmission unit that make it your choice for the OS Car powerplant? Unless you want a top speed of 149 mph, why choose the Wikispeed engine/transmission unit over a common mass produced engine/transmission with a bit less oomph and a lower cost (a Honda Civic or Fit, for example...or my first choice for bang-for-the-buck, the Geo Metro)? This is not a rhetorical question; other GVCS project vendor lists include surplus stock dealers so I know dollars count with OSE, why a Wikispeed engine instead of a less exotic and less specialized engine?

I added my comments to your comments (re 3 vs 4 wheels) on the http://opensourceecology.org/wiki/Talk:Car/Design_Criteria discussion page, and you've got me about half convinced. Man, you'd think how many wheels would be decided by now, wouldn't you?

-

I meant their interface standard. Use the same physical, mechanical and electronic connections. We can put whatever engine/trans unit we want in it, but they already worked out a way to quickly install/remove the whole thing.If we go with a 2-seater with 3-wheels we obviously don't need as much power. I'm not qualified to figure out what running gear to use, but it seems silly to ignore the work wikispeed has already done.

-

Yes, Jack, I'm serious about 350 lbs carrying another 350. I start my thinking from a velomobile, not a car background.

That 3 or 4 wheel page is getting tough to read. I have to agree with Jack's analysis, except for the problem of a tadpole going into a spin under braking. Very early in development, I made my rear brake a separate, emergency-only brake. I have it balanced so that there will be zero weight on the back wheel if you skid the fronts on dry pavement, down a 15% grade.

Some people try to reduce the frontal area of a trike by a gap between the main body and front wheels, but that takes careful detailing to come out ahead. I've spent many years pondering the various methods of tilt control. That is complicated by the superior overall performance of non-tilting tires.

To me, the main reason for developing a trike is the crash safety regulations, and the cost of compliance. WIKISPEED is locked into an approved chassis, which is adequate for a transportation appliance, but mandates much wasted space in some areas, and severe cramping in others. Perhaps it is naughty to provide vehicles which are versatile and fun to drive, when there are empty bellies to take care of. A farm-centered philosophy does not need much from a car.

However, I recall the cash-poor handymen of my youth being plied with jigsaws and sanders using their power drill as a motor, but they soon were able to afford a motor for each. Perhaps adding a simple power take-off to a car would make it plenty farm-friendly. My dad hauled bales with a box on a boat trailer, behind his Oldsmobile.

My main claim to fame is the integration of chassis and suspension through controlled flex in composites. I'm very interested in developing a scalable pattern that would give great ride and handling to anything from a velomobile to a horse-drawn wagon. I think it can be done in wood, although it gets a bit bulky without air springs for extra loading and adjustability, etc. www.microship.com/bobstuart/article1.html

-

Like, a 350lb car? Man, that would be a breakthrough.

-

> I meant their interface standard. Use the same physical, mechanical and

electronic connections. We can put whatever

> engine/trans unit we want in

it, but they [Wikispeed] already worked out a way to quickly install/remove the

whole thing.

Matt, every car is modular and lots of cars use subframes. For your example (the engine/trans unit) and using what knowledge gleaned from cruising the Wikispeed promotional videos, it seems the engine/trans is mounted in a subframe, and then the subframe is mounted in the chassis. This has some value for an R&D car (or R&D aircraft -- I've used the "firewall forward" technique to compare different aircraft engine types in one plane) if the engine choice hasn't been determined already, and if there's budget for different subframes but not for for different chassis. Instead of comparing two engines in two cars side-by-side, you can road test with one engine, then swap subframes to install a second powerplant (in the time it takes to change a tire, to quote the Wikispeed site) then road test again with same car, the different engine, and swap them quickly enough that test conditions haven't changed appreciably.

The downside is, adding a subframe adds weight and cost and weakens the finished vehicle. It increases (not decreases) the time needed to swap a given module (again, the engine/trans module is a good example) with a similar replacement module (e.g. swap a worn out engine with a rebuilt engine) because mounting the module to the subframe is the same job as mounting it to the chassis directly. If it takes an hour or two to put a fresh engine in a conventional car chassis, it will take an hour or two to put a fresh engine in a subframe -- you still have the same engine mounts to bolt down, the same wires to clip in, the same fuel lines and radiator hoses to plumb -- and then you have to put the subframe in the chassis. So maybe the final step (putting the subframe in the chassis) can be accomplished in five minutes, but the entire job takes longer than it takes without the subframe.

>...it seems silly to ignore the work wikispeed has already done.

It seems silly to ignore the work anybody has already done. Mazda uses a PPF (PowerPlantFrame) to tie the Miata transmission to the Miata differential (it's a front engine rear wheel drive car, which is somewhat rare these days) and since the engine is attached to the transmission, and the front and rear suspension are attached to front and rear subframes which attach to the engine and differential, this PPF allows the complete Miata driveline and suspension to sit on the factory floor as one unit that can be rolled around on its own tires. Then the body assembly, which includes the chassis and doors and wiring and fuel tank, drops on top of the drive assembly and 10 bolts hold the two assemblies together. I don't think we should ignore what Mazda has already done...and having considered it, I don't think we should make the OS Car the way Mazda makes Miatas, because it's unnecessarily heavy and it's expensive in small quantities. Besides, I know from experience that the Miata drive/body modulization doesn't matter once the car rolls out the factory door; when mechanics at a Mazda dealership want to replace an engine/transmission assembly, they unbolt it from the suspension subframe and the PPF, and lift it out through the hood opening -- and leave the subframes where they are, bolted to the body.

"Hot swap" subframes have their place, but for the OS Car, I think they're a solution to a problem that doesn't exist.

-

Aye. To get light weight, I try to get two functions from many of the parts. A sub-frame is more like getting half the utility.

However, on a trike, with no legal mandate for safety, I'm willing to make choices that give a big increase in crash safety for a small increase in weight. This might involve using a monocoque, even though it is a silly shape for the normal loads. If the toughness needed in a crash reduces the rididity too much, a sub-frame to maintain wheel alignment might make sense.

I recognize that my own bias is strongly in favour of having the finished artifact be light and elegant, and that production expedients are needed to supply basic needs to more people. I hope that this is just a phase, forced on us by all the current waste of resources elsewhere. The earliest mass production machinery, producing pulleys for the Royal Navy, included artistic embellishments for the operator's appreciation. Without aesthetics, we are poor indeed.

-

For those of you interested in the evolving saga of the OSE Car, I have posted all of the email conversation that has taken place recently to http://opensourceecology.org/wiki/Car/Correspondence. Email has the the advantage that everyone already has accounts and knows how to use it. On the other hand, it is not as transparent as the wiki or this forum, hence the posting of messages. There is quite a bit of interesting discussion on requirements, approaches, and the relative merits of the Kenetic Vehicles car and the Team WikiSpeed car. More interesting, perhaps, was my failed attempt to rationalize the process of organizing the project.

- Mark

-

Thanks for posting that. So Marcin's "reply all" button doesn't work, huh? So much for radical transparency.

Since when was "high performance" one of OSE's specs? Does he really think dropping power cubes into the Wikispeed car is going to be a "turnkey" solution? Oh well...I do want to support Wikispeed...I guess we'll see what happens.

-

Mark, that is interesting indeed. I just finished up a bunch of replies to queries and comments on the email group messages, and clicked the "discussions" button and found this one. So I'm about a day behind here on this thread. I'll leave it at "interesting" for the moment.

Mark, I hope you keep this up to date.

-

When the Model "T" started to hit high production, GM considered competing directly. However, they decided to accept trade-ins and sell used cars instead. I manage to keep a reliable car around for about $200 per year in parts and depreciation. I don't think I'd want an ugly, awkward, inefficient new one instead.

I was very impressed that WIKISPEED did their first car in three months, but they are now quoting twelve months to build a copy. In trying to work with them on composite develoment, I found that their projections were wildly optimistic. Ten minutes were allocated to brainstorming on a dozen possible mold surface treatments, but zero ideas have come out. I had to point out that thousands of others had been trying to come up with that answer for decades.

-

@Matt_Maier

> Thanks for posting that. So Marcin's "reply all" button doesn't work, huh? So much for radical transparency.

I think radical transparency is harder to practice than it looks, Matt, but it does seem unsporting that Joe and Marcin negotiated an agreement together and didn't tell the rest of us. I don't know how long ago they established the OSE/Wikispeed alliance, but it looks like even Mark Norton was left out of the loop until Feb 28, and he was facilitating the negotiations at Marcin's request.

It appears that Marcin and Joe settled their private negotiations considerably earlier than that, since there's a press release dated Feb 24 titled

Enabling Emerging Markets to Manufacture Their Own Ultra-efficient

Transportation, WIKISPEED and Open Source Ecology Announce Partnership

in Open-Hardware Movement

wherein the guys announced that they are teaming up to revolutionize transportation in the developing world.

The Press Release love letter (hey, don't look at me, that's what they called it) contains 750 words, including...

>>>

Together, Jakubowski and Justice will collaborate on a modular car,

which can be manufactured globally using only the Global Village

Construction Set (GVCS). OSE will adapt WIKISPEED’s current car designs,

making them compatible with their GVCS manufacturing infrastructure,

while WIKISPEED will provide automotive design, CAD for their current

ultra-efficient car, agile training, and efficiency consulting to

expedite design and development.

>>>

...so now we know.

I appended the text of the press release to the...

http://opensourceecology.org/wiki/Car/Correspondence

...page that Mark started a week ago, and I think we can stick a fork in that page, it's done.

If you want to see the original press release, with all the pictures and links and everything, go to...

https://docs.google.com/document/d/1hocj_UERHhz2XX6YDfRM6ELfI2Wr60VBbkp38Nv9rLg/edit

It's an inspiring document. Here's another excerpt:

>>>

Jakubowski calls the new collaboration a “bold and noteworthy step

toward the open-source economy, and it will serve to encourage other

change-makers to join the effort to invent distributive enterprise.”

>>>

I, for one, am so encouraged I can barely stand up straight.

-

Yeah, well, a little hyperbole never hurt anyone ;-PI think both groups have a lot to contribute to each other and, if nothing else, bringing all the intrinsically-motivated open source guys together is a good thing.I'm curious to see what sort of standards Marcin lays out for Wikispeed. He plays his cards a little closer to his chest than (IMHO) makes sense for an open source, non-profit, distributed volunteer project...but he's not stupid. This is definitely an opportunity. I assume he's got the money to simply contract Wikispeed to design the GVCS car from scratch, or to build a copy of their existing car, or anything else in that conceptual space. I haven't seen any indication that he has any idea what the GVCS car is supposed to do specifically...asking for it to be "high performance" AND use the existing power cube is a contradiction...hopefully the design conversation will be public.Personally I've enjoyed seeing the dramatic difference between how Marcin runs his project and how Joe runs his. They'll either get along swimmingly or blow up at each other. Oh well, that's enough random speculation for now.

-

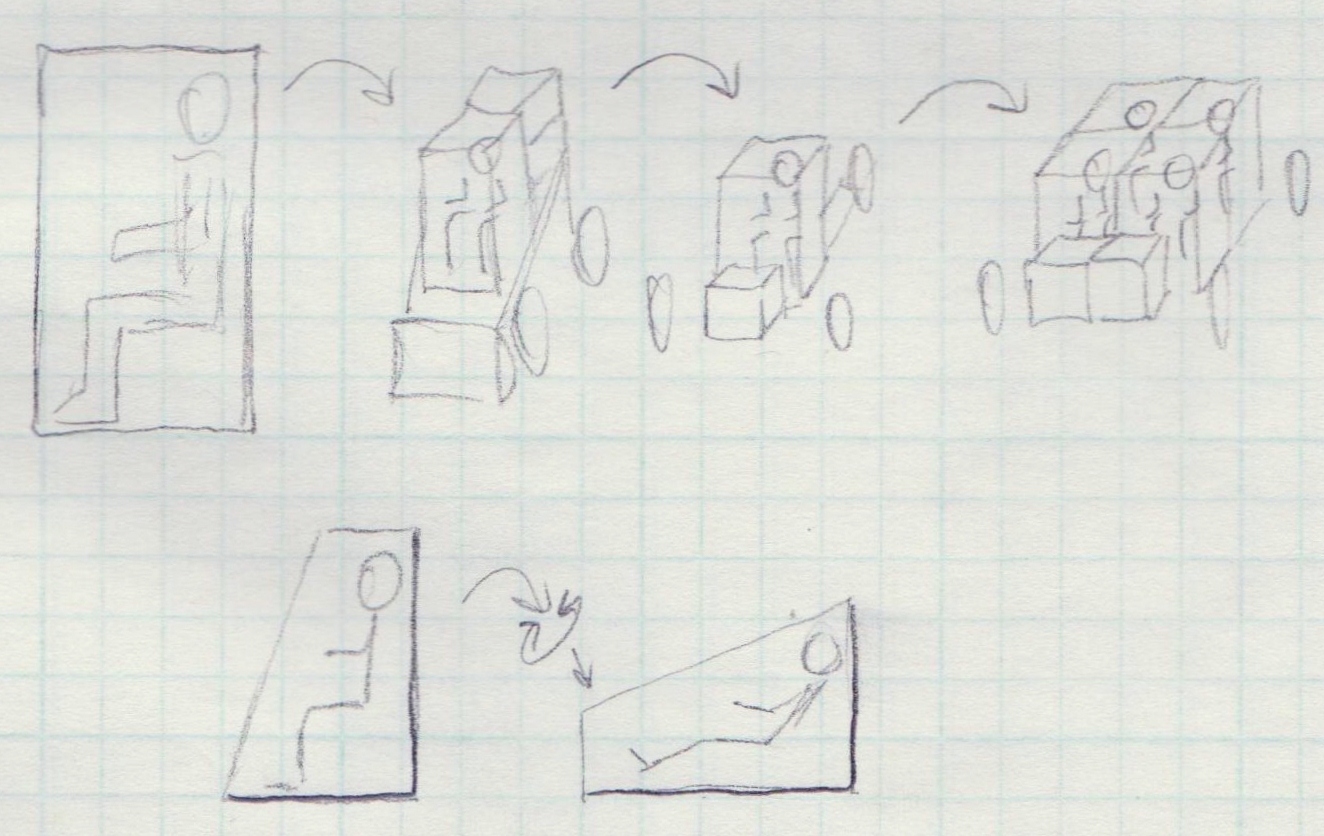

More thoughts on the GVCS car. The part that keeps the people safe and warm doesn't have to be all that big. Why not just shrink the crash cage and insulation down so it fits a single person? Then the cab could be moved from vehicle to vehicle or multiple cabs could be lumped together for larger vehicles. A little cleverness in designing the cab frame might allow different seating positions.Attachments

modular cab concept.jpg 403K -

This is great news, will be watching the progress eagerly.

I am involved in the management of many internal micro projects at the company I work for. Particulary the overall decisions around keeping a project in scope and on time. The number one problem that delays most projects is called the human ego. There are conflicts between people paid to work together as a team, so its facisinating to watch volunteers resolve their issues.

If we accept from the beginning that a lot of our ideas might not be used and that this is not a personal attack on you, this might help smooth the process.

I look forward to actually being able to build a car that I can use to travel my 60km a day as an outcome. -

AHHHH!! (slaps face multiple times)i totally screwed up my thinking of both the car and the truck. we shouldnt be making one single design, we need to make ideas and innovations that can then be used to build other cars for other places. I spent 6 hours today destroying (and i mean destroyed) road car by taking it on a fairly rough dirt road now think about a car for an american civilisation and now compare that with somthing that will be required for an african civilisation?

we need multiple cars all using similar designs and ideas.this is especially true in the form of a truck. An American truck would be a long haul on highways, Australians would be very similar possibly on dirt roads but a '3rd' world country would require more supsension, slower, etcanyone else understand this? -

Yeah, one of the changes to the GVCS needs to be a vehicle "kit" (like legos) rather than different vehicles.

http://opensourceecology.org/wiki/GVCS_Changes#Modular_Vehicle_KitThe problem is that nobody likes it when things they're used to, like cars and trucks, get big/heavy/ugly when they're made out of modular pieces (which by necessity are bulkier than specialized components). So, they tend to overspecialize on an "optimized" design. That means creating solutions that only work in one specific context.It's whatever. This stuff will evolve more slowly than other open source stuff (like software and electronics) just because it's heavier and more expensive. -

yeah ill be looking at a truck that can be built basically like lego, might even use lego to get my point across as to how to do it.my biggest problem is even where i am, in a civilised country things cost a lot more than america. So for me to do a prototype off my own back is going to be hard as hell and i can see that at this point in time a truck is one of the most useful things to have in nearly every country and hydraulics to me dont seem viable.what im proposing is a modular cab style vehicle using a common combustion engine driving the front wheels.basically you have a chassis with 2 front wheels, motor, gearbox, and steering and from there you build it into what you need whether it be a bus, truck, utility etc. ill make this its own thread soon and try and get some ideas rolling

-

You can see here where I collected information on the basic features of a wide variety of vehicles

http://opensourceecology.org/wiki/Modular_vehicle#Running_GearI sympathize with the expense. Hardware costs more to work with than electronics or software. I suggest working with CAD or RC-sized models first. You might look into getting a 3D printer (Makerbot, Ultimaker, UP!, etc) to make custom parts while you're trying to work out how all the pieces will fit together. Maybe paper craft would work. http://www.tamasoft.co.jp/pepakura-en/Let us know what you come up with! -

@Matt ive made a thread for the open source truckmean while through looking for random additions for my race car i cam e accross theseif we can make an open source version of these it would be worth it in my mind, and im too lazy and cheap to buy these things that i can do myself (i think)a hydraulic version would be possible, formula one used them and planes use them sort of (squish plate pump?

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Andy February 2012

- Bob_Stuart March 2012

- hafeez February 2012

- JackMcCornack March 2012

- Matt_Maier May 2012

- mjn February 2012

- qdelima March 2012

- spike May 2012