-

I approached Marcin awhile back about setting up a enterprise shop in the Philippines but never heard back from him.

I have proceeded along anyways with my project.

So far purchased and delivered to my home in the Philippines:

Torchmate 2x4 foot plasma torch table

P&H welder AC

4 hp air compressor

Complete set hand tools and power tools

Shop consumables for 6 months

Safety equipment

Spot welder

Harbor freight Mig welder

Still needed

Hypertherm powermax45 plasma torch

Torch consumables

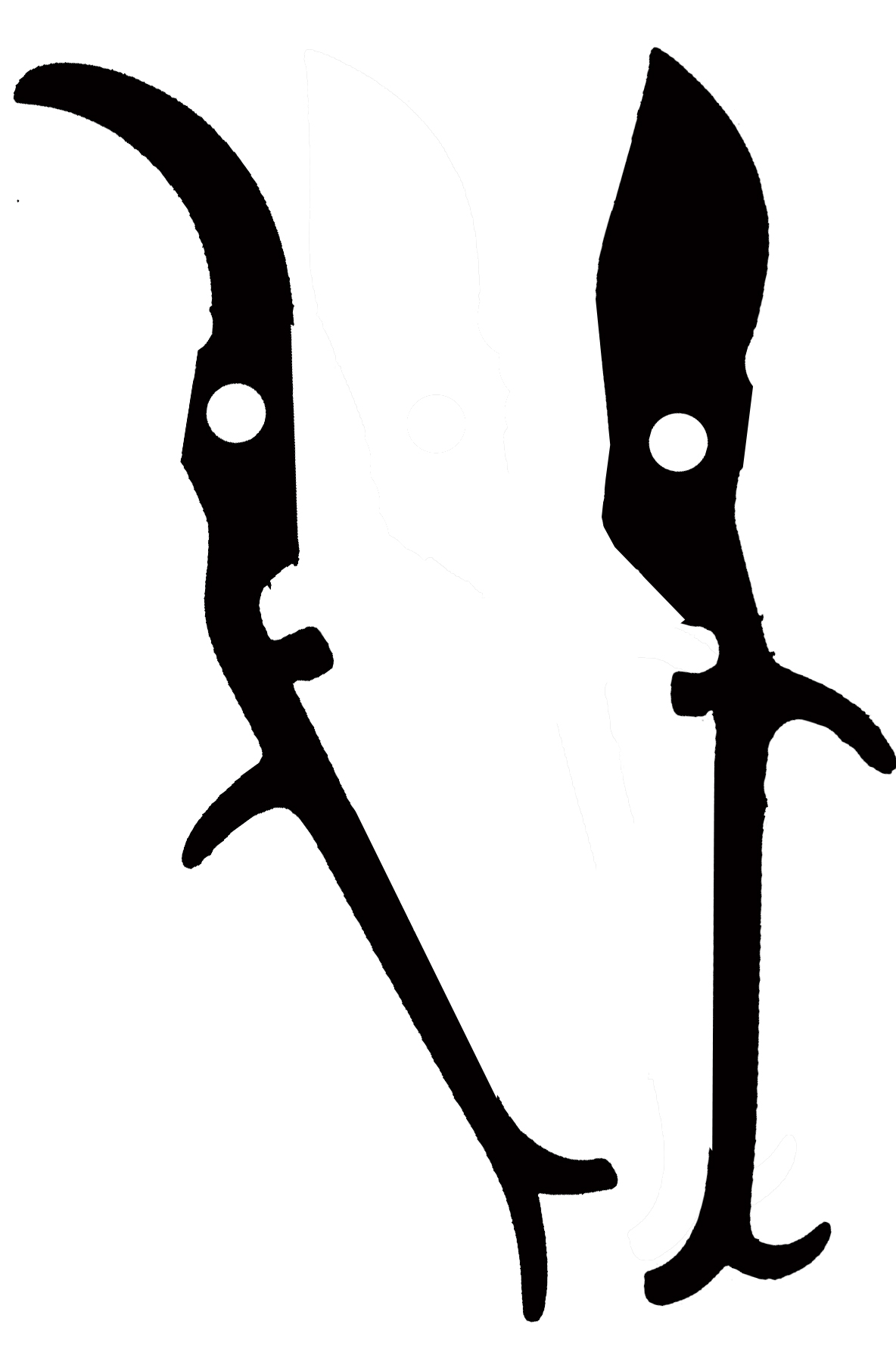

Torchmate CAD software

Solar cells from solar winds power

Battery backup

Universal power supply

Shop space will be start construction beginning of March 4 months from now. Planned shop area 800 square feet.

Last equipment purchase will be complete by Dec 1

Solar power is for backup power as the local power supply has a lot of brownout and black outs. Won't be able to run the machines but will be able to keep the lights on and computer running.

After setup the first machine to be made is a cinva ram CEB press. I know it's not on the GVCS but I will have the CAD files if someone wants to include it in the wiki.

Second machine is working on a wood gasifier to power a generator

I plan on initially offering the machines from the wiki in kit form as shop spec is limited and finances are somewhat limited.

Good news is that the venture will open debt free and rent free.

I will be looking to bring people from my area into the GVCS concept after opening and having a space for a live demonstration. -

67 Comments sorted by

-

I'm thinking about designing and prototyping some of e other machines ie oven that have not been started yet, as well as building a gasifier to run my backup generator, a manual CEB press for the shop walls,

With the documentation for some of the machines lacking at the moment, ie lifetrak I won't offer those up for sale yet. Just don't have the extra cash to spend 4-5 grand in experimenting.

I have several other tools designed now but I won't upload them to the community until The shop is running so they can be prototyped.

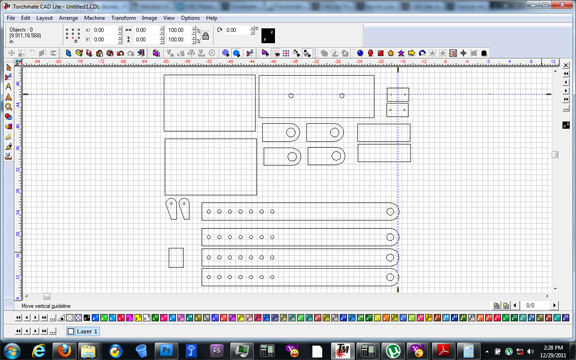

One area I see that needs improvement in the organization is in the area of hand tools. Since the GVCS takes tools to build, I was thinking adding dxf files for wrench sets, pliers, saws, etc to the wiki. I can easily scan a wrench on the flatbed scanner, import it into my CAD software and export it as a dxf file for the torch table. As a experiment I did this with pruning shears awhile back. It came out nice although the decencies in the freeware I was using came thru. Next month the CAD software is bought. Had to put it back a month to pay for a vehicle.

Im not suggesting that this be added on to the general mission, just added as a side note to improve the overall capability of a group starting with very little and building a entire civilization. -

Metz:

With the documentation for some of the machines lacking at the moment, ie lifetrak I won't offer those up for sale yet. Just don't have the extra cash to spend 4-5 grand in experimenting.Do You think You could sell the Lifetrac3 in the Philippines? Either in kit form or completely assembled?

I can hardly imagine that it will be legal on the Philippines to operate it on roads. Without regular steering and a dedicated brake system..Anyway, before starting to build I would examine the design in each detail. FeF has never published all drawings for the Lifetrac, but I am pretty sure they incorporated several NOT-TO-DO's in the design.

If You sell it You will have some liability for safety and probably a warranty for a year or soMike

-

Regulatory issues are not as big a deal in the Philippines, they run on the roads now with hand tractors attached to carts so regulatory issues are not as a big issue.

Initially though I will not offer the lifetrak because of documentation issues. For a small example I have seen very little on how the controls of the machine operate. I am competing with used imported equipment, so I have to build for less than that.

There is also the issue of finances. I don't have a huge amount of cash or work space, so offering something like a manual CEB press and sending the dxf files/documentation back to OSE is more in my budget and suited to the local market.

One thing I have not seen addressed lately is the mission of OSE in its applicability to the third world. Having lived in the third world for many years, I have gotten to learn the mentality. The GVCS is aimed at building a civilization where there is none or one that has been destroyed, in places like South Sudan, or Hati. Or in semi developed placed like the Philippines.

Just based on that experience I can tell you that if I was to build and offer to sell the present CEB machine, I would maybe sell one unit. A manual machine however that might cost a couple months laborers salary, will sell like crazy.

The lifetrak once it has been fully developed will probably be bought by construction companies as a low cost skid loader if it was cheaper than a imported used skid loader. I don't expect it to be of much interest to farmers when a day laborer costs $5 for 8 hours. Shovels are more Filipino farmers style.

Farmers on the other hand would buy large numbers of hand tractors if it was offered for sale at less than $1000 as the going price for a new Chinese machine is about $1200-1500US especially of it had a PTO to run a genset or tiller.

Wood gasifiers, if done right, will sell like crazy in the Philippines. Add in a briquette machine so they can use rice husk in a gasifier and it will be a huge deal. This is especially true for the remote islands. I envision wood gas powered boats, and compact modular gasifier units for tractors, generators and as a replacement for expensive imported bottle gas. Wood for burning is getting scarce, but there is huge amounts of agricultural waste that could power a wide range of industrial activities.

Regarding the open source car. Filipinos already have that. It's called the m38 Jeep aka owner jeep. Until recently there were large numbers of home made cars on Filipino roads. The last 4 years has seen a reduction as people have earned more money and credit has been more easier to obtain for new car purchases.

The Filipino jeep is sold widely in the US as jeep parts in the JC Whitney catalog. Since the m38 jeep is way out of patent, Filipinos have set up hundreds of small shops that make this vehicle all based on the original design.

-

Fair warning that if all the Lifetrac documentation were brought up to date to the point of when Ian made the video for assembling the frame and wheel mounts, deficiencies were found in the design in the hydraulic couplers which catastrophically failed, shearing and disabling the tractors. A fix was made, but to my knowledge, no one has documented it; the problem was a design flaw.

-

> One area I see that needs improvement in the organization is in the area of hand tools.

Funny you should mention that, @Metz. I was thinking along the same lines recently. Hand tools are necessary to build more complex tools - so where do you start? Drawing on some of my blacksmithing experience, I've started to write up An Evolution of Tools that starts with the bare minimum (hammer, pliers, a striking surface, and a heat source) and describes an order that leads to the creation of other hand tools and on to other tools. This is still a work in progress as time allows, but I've already described some how to make a new hammer from the basic starting point, how to make tongs, a chisel, etc. The actual construction details need far more work and should ultimately include photos/videos showing a blacksmith at work making them. While I could do that, my forge is in storage and not set up for production - something I hope to change in the next year or so.

I would welcome any comments or suggestions you might have based on your own experience.

- Mark

-

you mike talk to mike from http://www.opensourcehardwarecenter.com/#!contact about blacksmithing stuff. he's got a shop running. not sure what his interests are but might bounce the idea off him. he did a fef project visit at the beginning of the summer.

-

@mjn Part of my business plan is doing CNC plasma cutting. To demonstrate my services to potential clients, I was going to make some hand tools on the machine. After I got the dxf file its a simple matter to share it. I have to keep the shop equipment busy making money so when there are not open source machine kits being made for customers, I still can bring in income by just doing cutting.

I have several tool dxf files now, just need to cut them out and make sure they work. It will prob take one 4x8 sheet of steel plate to make every tool design in my library. At today's steel costs its around $150.

I was thinking of this as more of a side note in the wiki. You know if the project calls for 1/2 inch wrench, then if you dont have it or lost yours, you can fire up the torch table and make one.

It goes to the thinking that in the third world, sometimes replacements for lost/broken tools can be a complicated process. If there was a societal disruption some tools might not be available at all.I posted a vector file as a example below

Attachments

pruning-shears-vector-clean.jpg 131K

matchete-vector-jpeg.jpg 35K

sawblade.jpg 32K -

I love the idea of being able to cut your own tools this way. I think it's a great way to back-fill work. The circular saw blade especially caught my eye as it could be scaled up to create a large blade suitable to a mill. Ironically, you might be in a position to create the blade missing from the recent OSE Dimensional Saw Mill debacle.

-

Making a large saw-blade isn't for the faint-hearted, because it isn't as easy as it sounds. They're not perfectly flat, by design, they're slightly cupped or dished for stability and predictability of cut. The steel is probably best as more of a specialty steel, but that is probably the easy part. There would be tempering, hardening, & precision machining involved to make them compatible with the insertable-tooth design, and for a blade that small, there may not be teeth appropriate for it or practical, because of other issues, like wear, retention, jamming or fouling, etc. Going with a non-insertable-tooth blade means that it is then so proprietary that only you are the source of that item, and a single-sourced consumable part won't make anyone happy.

It is probably best to re-design the sawmill to take standard parts for those parts which are wear items, so they can take advantage of the commodity pricing all over the world.

-

I seen a television show awhile back from the UK where the shows hosts tried to recreate old machines.

They built a sawmill using a hand forged blade like a 2 man cross cut saw that was powered by water. It was powered by a simple crankshaft. We dont have to use water power but a power cube and hydraulic motor would work as well.

If a blade was cut from mild steel then heat treated and case hardened, or a more expensive steel used, would that work easier?

there would not be issues with balancing like a circular saw and the replacment blades could be made in house in keeping with the project ideals....

I will try to find the show again.

-

Yes, this is a classic frame-saw mill design, which was quite common in the 1700's and 1800's. It tends to be considerably slower than a band saw or circular saw, but it's also MUCH safer for that. This is something I've contemplated for myself. I don't mind if a cut takes 30 or 40 minutes, as long as there is either an automatic shut-off or it can safely continue to run at the end of a cut. I agree that a PowerCube could be made to operate such a device.

> Going with a non-insertable-tooth blade means that it is then so

proprietary that only you are the source of that item, and a

single-sourced consumable part won't make anyone happy.

Actually, I don't completely agree. If CnC files are made available via open source, anyone (in theory) could at least cut their own saw blade using a plasma torch table. Granted, most people won't have such a thing, but it IS part of the GVCS-50. Fixed-tooth designs should be easier to work with, such as sharpening the teeth. Tempering it might be challenging, but I think it could be done. A replaceable tooth design is better for production purposes, but if a fixed-tooth saw blade could be made up in a day or two's time, it might be economical for small-scale production. We could trade off a thicker kerf for greater stability in motion, which might avoid the need for cupping, etc.

- Mark

-

@mjn The books by Gingery have explored the same idea. Starting with the first book on foundries, he then uses it to build a lathe, and the lathe to build other machines until he has a full shop. He explored how the early machine shops were build. There was no place to order many of these new machines at the beginning of the industrial era so enterprising machinists built their own machines based on often times sketchy trade magazines and books.

regarding saw blades and steel quality. Maybe we can look at recycling other items that already have a good quality steel in them like leaf springs?

I am dreaming of a pick ax made from a used leaf spring, cut by a plasma torch.

-

I have not heard that being a issue before. The manufacturers forum for the CNC machine has many examples of knife makers work using the machine and plasma torch.

They have even combined forging and CNC by hammering cnc cut parts while hot to give it that wrought iron look.

-

@mjn

My one concern for a CnC plasma torch would be that it might burn high carbon steel. It's possible that the process of cutting the blade would ruin it for making an edge on teeth.Never heard about an effect like that. I know of no recommendations not to do heat cutting (torch, plasma etc) with HSS and high carbon steel ! Small metallurgical changes at the surface, if they really happen, will be reversed by hardening and tempering. Also some tenth of a mm at the tooth surface will later be removed by the thorough grinding process needed for a new blade.

Don't confuse this torch cutting process with applying excessive heat to an already hardened tool - high carbon steel starts to loose its hardness with temperatures above 200°C, whereas HSS can stand nearly 600°C.

-

Update November 17

Getting solar power get up. Got donated a 600 watt 220v UPS with a bad battery. Took out the battery, will run it as a inverter using a larger battery.

Also donated to the cause is a 150 watt 120v inverter delivered yesterday.

Last week finally got a shop vehicle. Picked up a 1996 Chevy Astro AWD. looking at converting to a carburetor so I can run a gasifier with it. The engine is the same as in the Silverdao pickup and has a 5000lb towing capacity. Need a good tow capacity to haul steel back from the supplier and to keep a low profile by not using heavy trucks for deliveries.

Next Thursday I place order for the plasma torch. $1900 (ouch) I could go a lot cheaper but I would be trading cut quality, durability, ability to operate in large voltage ranges, and duty cycle by getting a cheap torch. I want a setup that can cut steel all day long with a couple thousandth of inch repeatability.

Looking at my electricity needs. Wish I could go totally solar, but the budget is not big enough for that. The plasma torch alone draws 5kw. At least the lights, computers, tv, fan, and internet will be solar. I figure I will need a 50 amp 240v circuit which means running power from the meter to avoid screwing up the house circuit.

For some reason my home was built without a 3rd wire ground. The contractor for the developer got caught shaving things off the build and embezzling money. We watched him closely, but still he slipped that by us. The neighbors across the street and next door who live in the UK and the US were not so fortunate. Their homes were built with very poor material. I would hate to have to live there full time.

The house still has maintenance issues. The plumbing is all pvc and leaks in a few places. I guess this gives me a excuse to put in a cistern, run new copper lines and go off the grid for the water.

All in all things are really coming together. 107 days or so until construction start.

-

Running a ground isn't the worst thing that has ever happened - I still have to do that in "Modern" houses here from time to time. Is your wiring in conduit, or is it NM-B or similar? (Hopefully it isn't BX, although you could probably ground that easier)

The PVC leaking is probably bad news, because that almost means that they skipped using primer on the joints, so any one that wasn't perfectly clean will have only partially solvent-welded, and you still wouldn't be able to take the joint apart, even though it wasn't water-tight. PVC may still be a good replacement, depending upon the price of copper, (use CPVC for supply lines, not standard PVC), but make sure you use both the primer & cement, and it will last for decades or longer, barring fire.

Do you have enough of a prevailing wind to make putting up a wind-generator feasible? That may be a good supplement to solar power too.

-

I will look at wind later but for now I got a full plate. I like the Axial flux generator design.

As for the plumbing, I suspect it was just sloppy work by unskilled workers. Im going with copper lines run on the outside of the house alongside the trim. There is no way to run pipe inside a cement block wall after it has been built. Im choosing copper cause of its antibacterial properties and because it will be exposed to the weather whereas PVC has a chance of failure from UV degradation.

-

I am in the process of setting up a shop for GVCS building... however I don't have much experience in this area. Could you tell me if a 240 volt welder is required? Or is a 120 volt welder adequate? Also does anyone have a list somewhere of what shop equipment I should have to build a power cube?

Metz- My house also does not have any grounding. I am in the process of fixing it-- it was built in the 1950s. It was built with conduit so I have been able to pull new wire through the conduit when I had to rewire the kitchen (long story). I would have to dig a trench and run new wiring out to the garage if more than 120v is going to be required.

mjn- your website is great, I'm still reading it.

-

tom is probly the best person to talk to about power cube. he's buulding one in gis garrage with limited shop tools so he'd be doubly good to talk to.

http://opensourceecology.org/wiki/Tom:_Dallas_Log

hes been posting updates there.

hes building a tweaked design so i dont know what all that means as far as tools.

i dont know his email but you can contact him via the wiki or msybe his email is on there somewhere :P -

As far as welders go, you can get 120 volt welders, but you will find that those tend to be on the lower end of quality and longevity, so if you only wanted to buy it once, you'd do better with a 240 volt one, but it is your choice. You'll also find that the capacity and capability of welders will go up once you aren't limited to 120 volts, because for the same duty cycle, you can utilize twice the power.

-

I will second that. 220volt. Where I live everything is 220-240 volt so 120 is not really a option.

Look for the most welder you can get for your money. One of those big red Lincoln stick welders, or even better a used P&H welder will run you a couple hundred. If you have a larger budget get a Miller Mig welder. The harbor freight mig welders are not very good. Hobart are OK but they won't run all day like the others mentioned. -

Cool, sounds like I will go with the 240 volt model then.

I posted a note on Tom's wiki user page to find out what other tools he is using. Although I see he posted some in his blog it would be nice just to have a list to check off what you need, similar to the BOM.

-

im a fan of tool lists. i try to fill in a little section about "tools required" if i know. the problem that people usually bring up is that some tools are interchangeable. like a saw and a torch can both cut something, so what would you put on the list. or if you have access to plasma cutter u wouldnt need the more basic stuff. i just assume the answer is anything listed is better than nothing.ive been hoping for something like how thingiverse has profiles u can list all your tools and then that could show you what all you could make sort of thing. who knows someday.but anyways if u see a gap you think should be filled in go ahead and write in what you know and make a note of anything youre not sure of in the page's discussion tab.

-

Plasma torch+air compressor is deff towards the top of the list.

I got the Hypertherm Powermax45 for my shop. there are others a lot lower price but I wanted the clean cut and ability to run all day without overheating. If I was on a tighter budget, i would look at the Hobart or maybe the Longevity brand.

A word of caution, many plasma torches do not play nice with CNC plasma tables, something about the high voltage spark that starts the flame feeding back and frying the controller board. You will have to check with your manufacturer for compatibility and then double check with someone else to make sure.

-

Update Dec 5, 2011

86 days to construction start.

Watching the world economic news, especially Europe. Hope things do not fall apart. I am not at my house right now, on job site about 11 hours by plane from home. (still in Asia)

Have one manual CEB press pre-sold. Have a couple tentative sales for manual CEB machines lined up.

Getting interest from a coal broker to sell gasifier machines.

Things are coming along nicely so far.

-

Update Dec 27

More shop consumables arrived today. This was a box of plasma torch tips. $250 for a tiny box ouch.

Bought the CAD software couple weeks ago, it does not work in a digital download cause it requires a dongle. It's somewhere between NJ and Asia right now in transit.

Distributed my own version of a civilization kit. My company is laying off over a thousand people. Several Indians I have worked with the past 2 years are going home. I put together a CD of the manual CEB press, and public domain farming/carpentry books for them to take home. At least they can use the CEB press to earn a living.

I was really looking for the GVCS DVD to give them too, but can't find it here, and they are leaving in a few days.

Got a unexpected bonus the other day. Getting my unused vacation days paid in cash when I leave. US$4600 to the cause.

I am on a job site for my work for another 2 months, shipped home most of the household goods couple weeks ago, got A few more boxes to go out next month. 60 days transit time by ocean cargo.

Got behind on ordering the solar cells, Christmas and related expenses came up. Hopefully next week the solar cells will get ordered.

Only one more $350 order from the US is needed. A plasma torch holder for the CNC table. Have almost a years worth of consumables put up.

Looks like I will have a years worth of everything to get started. Food, shop consumables, money. Planting a garden to offset the food costs. The wife has made the executive decision not to plant until I get home however.

Next month I will send the wife to the carpenter for construction estimates. I have a pretty good idea the costs already. It should be 4-5 thousand tops for the shop space.

65 days or so now.

-

Update Jan 11.

Have spent many hours learning my CAD software. I didn't get the full version so it did not have tracing or auto parts nesting feature. Found Inkscape which works very nice for tracing drawings to import into my CAD. Still having issues exporting a dxf file from my CAD program.

Counting down the days, and working up the budget. We are paying as much bills in advance for a year as we can to eliminate budget headaches. With the coming financial problems in Europe and the US, I am pretty concerned about staying open.

I mean we are already in a slow motion collapse, but things seem accelerating from my vantage point.

Also taking a side trip in March to China. For me to get a year visa I have to enter the country with my wife. Since I am off on a job site in Kuwait without the wife, will have to fly home, get the wife, go to china or some other country and re enter together. 4 day 3 night tour packages to China including air from Manila are around $200 each.

My work takes me to interesting places.

Got 2 pre orders for the manual OSRL CEB press and one person has expressed a strong interest in buying a OSE CEB press.

This is the model of torch table I have, Mine is still in the box till I get home.

Here is one of my welders. It looks kinda crude and old but it actually is better quality than a lot of the high dollar welders on the market today and was only 300 dollars.

Attachments

torchmate.jpg 44K

welder.jpg 28K -

Update Feb 17, 2012

Wow time sure has moved fast.

All my tools and gear shipped by sea has finally been delivered. Was in a sandstorm last week, and came down sick, spent about 8 hours in the hospital with a IV drip. Finally got back to work today, unsteady legs, hacking cough and all.

The torch holder was delivered by UPS last week. Prices went up again for tools. Ended up costing over $500 for a 9 pound box shipped from Reno to Philippines.

Have the household goods mostly packed at my company provided apartment. Only thing left is a few changes of clothes, computer, DVD, and some food. The local stores here sell canned food at a reasonable price so I am filling up the empty space in the household goods boxes with canned food. Inflation insurance.

Looking forward to getting out of this place here and back home to start work. As of right now I am sitting about 100km from Iran. Much of the food here comes from Europe. Not a good place to be, with the Euro crisis (see Greece)threatening to spread, and war clouds on the horizon.

My postal service was cut off early here. So I still have not gotten the solar cells ordered. Have the inverter, no cells. Will have to have them shipped by sea from the US instead of trans-shipping them thru here via the US post office and then by sea from here. Sounds confusing I know. I have US Mail service over here which is at the domestic US rate and shipping by sea to the Philippines from here is cheaper than mailing it to Los Angeles and then by boat to Philippines.

Still dealing with a headache here. My boss has threatened not to pay me out my final salary owed. I and my co-workers have raised all sorts of stink since then. It is a pretty big sum of cash.

Don't have a plane ticket home yet. One is supposed to be provided. Most likely in the first or second week of March. They have to get us out of the expensive condos they rented for us, so figures they will get me outta here ASAP. Last work day is Feb 29. -

Well 2 more days of work. Then waiting for my final paycheck and plane ticket. Still controversy over here with my employer.

Looking forward to start shop construction. I have really started getting the hang of using the CAD software. Spent 15 hours manually tracing a photo of a ancient Greek vase in the cad program to cut it out in steel. I could have used a tracing program, but when tracing a bitmap, many times too many nodes are created and this causes the machine to cut the design rough as it follows the excessive lines of gcode.

Still keeping a wary eye on Iran situation. I fought one war, I'm not fighting another.

Anyways if all goes well, in a week or so, will jump on a plane going home. Then a short trip to Hong Kong. I will check out the famous night markets for the latest electronics gear. Maybe get a arduino board on the cheap. -

Hello Metz,

My name is Aaron, and I am writing grants for OSE full-time. Do you think you could help us out by writing up a document about your plans and your bio - that would go a long way to adding even more value to our grant proposals.My email is aaron at opensourceecology.orgThanks,Aaron -

Update March 18 2012

I am finally home and construction begins Monday morning. Had first load of materials delivered Saturday.

Manual CEB presses are the first product being built, Along with a improved soil pulverizer/screener design. Have had serious inquiries for the fully automated OSE design this weekend also. I showed a video of the OSE machine in action and they were very impressed. One thing is I will have to make stabilized CEB for the local rainy climate.

Lots of work to do the next couple weeks.

-

-

Day 4 construction update:

Work crew has finished setting up concrete forms, rebar, electrical, and water this afternoon.

Had a couple changes to the shop size and had to change location of shop to front of house instead of back of the house, due to utility issues. Went smaller so I could afford a totally enclosed shop. Have some security concerns so it is better to have walls.

Tomorrow we pour concrete. 6 cubic meters of 3000 psi concrete. Crew of 7 pouring by hand cause a concrete pump was more than the cement cost. It is one load of concrete, should take 2-3 hours to pour using buckets.

Concrete will set up and next week most of the forms will be removed. Garage door installed, and walls put in. I am recycling the wood used on the concrete forms for the walls. Had to forgo the cement board and metal studs. Not ideal but had a small budgetary setback.

My 4.5 horse air compressor gave up after a hour of use. It uses a oddball mounting bracket so I can't buy a replacement, and it would be a couple weeks to get the motor rewound. I went to the tool shop here and they had a big air compressor for about about $1000 dollars or two- one horse air compressors for $500 dollars. I got them plumbed in parallel and have had 2 days with it powering a air chisel we are using to chip concrete. Seems to work good enough.

Running serious electrical service in the shop. One 60 amp breaker for the plasma torch, 6 outlets at 30 amps, and one outlet at 20 amps. It is set up to convert to solar/ generator when the time comes for that.

My aquaponics system has nearly all the parts needed except a couple of 15 and 30 watt aquarium pumps and 2 liter bottles. That and time to put it together. Planned usiing grid tie electricity initially, with UPS battery backup and later solar with grid backup. I have finally figured out how to wire this system together.

Shop will be running second week of April. Have to go do family things for Easter Holy week. So a week after that.

The wife is coming around to converting to using a rainwater cistern system instead of community water. We have really hard water and we go thru a shower head every 6 months from the lime. Don't know what it is but it does not react with muratic acid.

Lots of enthusiasm for a wood gasifier, and CEB machines here. I am looking forward to doing some creative work again. -

Video of evening rain after concrete was poured. Ends with showing the aquaponics system.

Got

last meter poured. Heavy rain came about 4 hours after the concrete

set up. I dont have enough plastic tarp to cover the whole project,

hope i dont have problems.

-

Concrete forms are off, and working on topcoat today. the rain messed up some of the surface that had to be chipped away and re-poured.

Started putting together the torch table base yesterday but I am under the weather so I have to take it easy the next couple days (docs orders)

I took a quick video, lot of equipment sitting around, wont pull everything out of the boxes and set up until the walls and garage door is up. Got one shop helper hired part time for metal fabrication.

the video has a quick shot of the future aquaponics system. The plants are shading it and keeping the algae growth down. It is full of frogs now, but they will be removed and more edible fish put in later. The frogs are competing in a nightly chorus with the 100+ roosters, barking dog, and chirping lizards at night here.

Weather is between 28-33c. no need air conditioning. If I had the solar in right now I could power most everything except the fridge and shop on 500 watts.

-

Awesome. I'm looking forward to seeing how the business side of things works out. There aren't many case studies invovlving open-source technology.

-

Day number 11 of construction.

Concrete poured, forms removed, flooring done, walls up by this afternoon.

Electrical is going in now. Still need to plumb water for the sink hopefully Monday. I am putting in heavy duty electrical, 8ga wire, new ground rod. The existing electrical we discovered to be really poor quality so we had to rework a lot of that also.

Overhead garage door will be installed Sunday.

We have been recycling a lot of the construction materials as we go along. Recycled door/jamb, Reusing the concrete form wood in the walls with lots of anti termite preservative. Recycled exhaust fan, reused electrical outlets, one reused light fixture. We are even reusing the nails from the concrete forms by hammering them straight and using them again.

I took a small video if the in progress aquaponics system in the rain here. I am planning on converting to rainwater collection system and going off the grid for water. My water bill now is only about $15USD a month, but that is money I would rather not spend and the water service has very hard water that has meesed up the fixtures.

Ideally I would like to go totally off the grid in a earth ship sort of way without the earthship odd looking construction. I am more towards the resilient living lifestyle than the green hippie living thing.

So far we are on budget. Total shop construction should run about $6000 USD. Not too bad.

-

Posted a few more photos of the shop.

First picture is my dwarf coconut tree. We planted this from seed in 2006. This is the first fruit from it.

Here is a banana tree in the vacant lot next door

Exhaust fan installed today

Recycling used nails, bending them straight and using them again. these were from the concrete construction.

We also reused chain link fence section today as concrete reinforcement in a sidewalk section.

Installing lighting wires above. 8ga wire. Good to convert to low voltage DC in the future if needed.

Lower photo, fuse panel. Going overboard with the wiring a bit. Better safe than sorry.

__________________ Attachments

Attachments

concrete8.jpg 91K

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- aaronmakaruk February 2012

- Allen15 November 2011

- Bastelmike November 2011

- BrienTH December 2011

- Dawg April 2012

- dorkmo December 2011

- eBell April 2012

- Howard_V_Agnew November 2011

- Matt_Maier August 2012

- Metz July 2013

- mjn April 2012

- Nikolayhg October 2011

- Rondon December 2012

- RootBeer November 2011