-

Marcin recently posted a blog entry that lays out a plan to design, develop, and prototype the GVCS-50 by 2013. The original post is at http://blog.opensourceecology.org/2011/07/towards-50-gvcs-tools-by-2013. I have summarized it into outline form at http://opensourceecology.org/wiki/Towards_50_GVCS_Tools_by_2013.

This is an important statement from Marcin as it clearly lays out his plans for OSE for the next year and a half. Some questions come to mind that I post for general discussion:- What can we do to improve the chances of success for this plan?

- What additional roles are there for remote volunteers?

- How can we find the subject matter experts that will be needed to design the remaining GVCS tools?

- How can we make the process more efficient?

Marcin is clear that most of the action will happen at Factor e Farm. This is not a coincidence. Part of the goal here is to model a small community that has the capability to move beyond the constraints that our current economic situation imposes on all of us. As Marcin put it in his blog post, "One successful example of a post-scarcity economy can and will change the world." That being the case, I am quite interested in how the rest of the world can contribute in a manner that we will all benefit from. I see a great role for non-resident volunteers to be information gatherers, documentation organizers, networkers, fund raisers, etc.

I am committed to the goals and visions of OSE and the GVCS describe by Marcin in his post. Who is with me?

- Mark Norton

-

111 Comments sorted by

-

It seems to me that the only way to meet that goal is with parallel development, not just on Factor e Farm.

How can Factor e Farm develop the remaining 40+ tools in the remaining 17 months? That's a tool every 13 days, and they have taken at least a year each so far (often more like three years).

I think the way to develop 50 tools is with 50 teams. First, we need clarity on what process each of the tools needs to go through, and we need a solid collaboration platform. Then we assign each tool a project manager (who need not necessarily be technically expert) to walk through the development process. These other teams may need funding from OSE.

Also, we should leave tools to other open-source groups wherever possible. OSE itself need not worry about designing a 3D printer, a car or a laser cutter - there are already open-source groups working on that.

-

@Conor

> the way to develop 50 tools is with 50 teams.

There is a lot to be said for this approach. Parallel development could significantly reduce the time it takes to reach a complete set of GVCS tools Naturally, there is overhead with this approach, as you imply with the needs for process and collaboration tools. Personally, I'd be included to let standards emerge as the process unfolds, since designing process and standards could take as much time to do most of the projects.

> These other teams may need funding from OSE.

My guess is that Marcin is unwilling to fund development efforts outside of FeF. I believe he feels that there is a process in place at FeF led by him that allows rapid development and prototyping to happen on any given piece of technology (though this is yet to be fully proven).

> leave tools to other open-source groups

While not exactly an "OSE Policy", there does seem to be evidence to support the idea that OSE will partner with or leverage other open source projects. RepRap and SolarFire come to mind. Perhaps what is needed is a formally way to recommend another project. Thus: "For 3D plastic printing needs, OSE recommends building and use the RepRap Mendel printer."

- Mark

-

> While not exactly an "OSE Policy"

I don't think anyone at all is clear on what is OSE Policy and what is not. RepRap and SolarFire are precedent, and that's enough

> Perhaps what is needed is a formally way to recommend another project.

Thus: "For 3D plastic printing needs, OSE recommends building and use

the RepRap Mendel printer."

I really like this idea. We just need to post the recommendation clearly on the wiki, specifically on the GVCS list and on the page for that specific tool

-

yeah i have to agree, maybe setting it as having access to 50 GVCS?and instead of having them completed just at a design phase?ive found a couple of different ideas, designs from organiseations like OSE, some are even linked in the WIKI.also just looking for 50 machines would be difficult for me.id like to help, but its hard to find people like minded in Australia and due to it being so big very few are in my area

-

I would agree that OSE policy is a bit murky these days, Conor.

- Mark

It looks like OSE policy its a bit like a cat chasing its own tail !

Examples:

because we have no working induction furnace, we don't use castings in machinery designing....because we have no working fantastic multimachine, we don't use precisely turned, milled, grinded parts...because we have no CNC torch/plasma cutter, we don't use adeaquately formed parts in our design...because we have no really working open source (3D-CAD), we produce bad looking drawings or use inapt tools like google sketchup...What does OSE want first? Building everything starting from a scrap yard?

Or developing open source designs for those 50 tools?Wouldn't it be a better start to develop the designs for tractors, cars, trucks, CEBs, wind turbines etc first? So anyone who has appropriate tools could replicate them? And in a second step develop the designs for own machine tools of all kinds?Instead of limiting all current designs by what FeF can manufacture now?OSE has a multi-millions dollar budget, so don't tell me, they couldn't afford to buy appropriate (used) machine tools or commercially built components like castings.Mike -

mike i dont think its the aim, yes we could buy things to build everything we need but what about the people who cant?

maybe setting the system up smaller than anything? using simple hand tools to make mill, using scrap components to make a basic flame forge?

-

The OSE specifications are in the wiki. If they are not to be changed, one should take them a bit serious.

They call for high performance and industrial efficiency. GVCS tools should offer equal or better performance than commercially available hardware.

They call for a lifetime design, machines should have a useful lifespan of many years up to decades.This calls for high standards in the design, the quality of raw materials and manfacturing quality !

In contrast, there is no sentence in these standards that demands that OSE tools can be manufactured with raw basic tools and materials from scrap. It is impractical to design the GVCS tools in a manner that would allow to manufacture them without tools and capital to buy materials and components.

I personally believe that GVCS can substantially improve the lives of many people in the developing world - but for people who own don't possess a cent and have nothing to eat, the only solution will be humanitarian food aid and not OSE.Linux is a success story because it is equal, I guess even better, than a popular commercial PC OS. If it would be inferior to MS W...., no one would talk about Linux any more

Mike

-

yes i will have to read over them later, i will see about downloading the whole wiki.

and yes we should aim to eventually build things with an unlimited lifetime and performance but when you consider the history of the world. you cannot start with building things without the tools, first we must make the tools, and in my sense it is building the tools to make the tools.

-

Obviously, some amount of boot-strapping will be needed to realize the end goals of OSE. We need tools to build tools and rather than knapping flint, we can start with a used lathed from Craig's list. Still, the idea is that once we can build our own lathe, then we can help others to build theirs.

@Bastelmike - OSE and Marcin are trying to work out designs that will work. It's a slow process made slower (IMO) by centralizing things at FeF. Still, it is an approach that seems to be bearing fruit. Like most people on this forum, I want the whole of the GVCS-50 RIGHT NOW! Not gonna happen right now or in the next year for that matter. Still, slow progress is better than no progress.

- Mark

-

@mjn

We all in this forum probably want the GVCS50 designs finished tomorrow morning, but thats just a dream. If we get 50 high performance and quality designs by 2013, we will be happy.But my optimism regarding this is dwindling. Not because of the deadline, but because of the standard of the machinery developed.

There is clearly a trend by FeF/OSE currently to sacrifice performance and useability for ease of design and manufacture! Continuing this road will result in 50 finished designs who nobody wants to own, at least nobody in the industrialized world. People there know the performance and efficiency of commercially built machinery, they dont want to go several steps back with OSE.Most designs aren't ready, but as they appear now, it won' be possible to sell and operate them in my country as they don't confirm to current laws for safety and ecology. Mark, do You really believe You will get a road permit in Europe for a Lifetrac3 with skid steering and without independent brake system???

Besides this issue the standard of many details in machinery design is like the standard of most of the OSE drawings: I would call it poor.

mjn wrote

My guess is that Marcin is unwilling to fund development efforts outside of FeF. I believe he feels that there is a process in place at FeF led by him that allows rapid development and prototyping to happen on any given piece of technology (though this is yet to be fully proven).

Until they convince me of the contrary, I doubt if FeF will produce any design and the technical documents like drawings for it, so You can go with it to a local machine shop without getting laughed at.

There is still a lot of progress needed to make OSE a success story !

Mike -

Hey Mike,I'm hoping to jump on board on a few of the projects soon and try to get some legitimate drawings done for FeF, stuff that a machine shop won't laugh at you for hahah....I'm finishing off my last couple weeks at my current job then I should be able to start dedicating some time!- Mike

-

> There is clearly a trend by FeF/OSE currently to sacrifice performance and useability for ease of design and manufacture!

While I agree in principle, we do have to consider our scale of operation. Looking at it one way, OSE is a farm with 5-8 people led by a Physics PhD. In order to accomplish anything at all, practicality rules. Personally, I think they are striving for good performance, but there is more than one way to judge that (power, ease of control, etc.). They are doing the best they can with what they have. To some extent, this is a consequence of focusing and leading all development activity at Factor e Farm. In my opinion, this linearizes development and limits what is possible. I think that a massively parallel, distributed effort could lead to far better designs. However, OSE is not set up to manage such an effort.

> the standard of most of the OSE drawings: I would call it poor.

The quality of OSE drawings is limited in part by the desire to use open source CAD tools, which themselves are very limited and in an early state of development. I for one do not have thousands of dollars to drop into buying AutoCAD or something similar just to work on OSE for free. Furthermore, there have been many offers by experienced CAD developers to help with the OSE designs. Again, due to the lack of organization for distributed, remote development, such offers have languished, and we are left with the best efforts of FeF.

> Mark, do You really believe You will get a road permit in Europe for a

Lifetrac3 with skid steering and without independent brake system???

No, I don't. Things are a bit different here in the states. Most farm equipment is allowed only limited access to public roads and therefore do not need to meet the rather strict requirements set for trunks, cars, etc. Still, I agree with your assessment - the LifeTrac doesn't meet most standards for a good tractor, especially safety-related ones.

- Mark

-

mjn -

The quality of OSE drawings is limited in part by the desire to use open source CAD tools, which themselves are very limited and in an early state of development. I for one do not have thousands of dollars to drop into buying AutoCAD or something similar just to work on OSE for free.Okay, but thats just one aspect. The other fact is that 2D-drawings are substandard in my opinion too.

- drawing header is missing

- material for parts not specified

- no standard tolerances for free dimensions mentioned

- always, geometric and dimensional tolerances are missing

- symbols for surfaces are not usedThere is a set of lifetrac drawings on the web, where in the header is specified, that "all dimensions are in mm, if not otherwise specified". But I don't believe the Lifetrac is only 80 mm long !

That's disastrous if ever parts have to be manufactured in a large company where no machine operator knows what the parts are for...I don't know how good open source tools are for 2D-CAD today. But anyway, You can buy commercial CAD software like Autocad LT, Autosketch or Turbocad 2D for less than 50$. And all these programs are good enough for correct and presentable 2D-drawings.

Furthermore, I have downloaded OSE drawings as .iam and .sldasm files. So obviously some people making OSE designs hae access to high-priced CAD software like Inventor and Solidworks, there is not much room for excusions because of bad software. Thats by far higher priced as I have for personal use.Just these few sentences to the subject bad open source CAD software.

Mike -

Hey Mike,I'm hoping to jump on board on a few of the projects soon and try to get some legitimate drawings done for FeF, stuff that a machine shop won't laugh at you for hahah....I'm finishing off my last couple weeks at my current job then I should be able to start dedicating some time!- MikeHey Mike,I am looking forward to Your designs. Hopefully they give OSE the urgently needed progress towards state-of-the-art mechanical designs.Mike

-

@Bastelmike I accept that you know more about this than I do. You are right that the folks at FeF have access to professional grade CAD software, so in theory they are capable of producing good drawings. That they are not speaks to lack of experience. Unfortunately OSE isn't really set up to utilize more experienced people if they are no co-located on the farm. As such, the quality of documentation produced will be limited to the experience levels of those willing to live in Missouri for a time.

- Mark

-

Practicality rules......

mjn:

As such, the quality of documentation produced will be limited to the experience levels of those willing to live in Missouri for a time.I am afraid, not only the quality of documentation will be limited.

The quality of designs and realization is suffering from this OSE policy. Most volunteers at FeF are young people without experience and without good education in engineering and design. For the quality of the Lifetrac see this thread:http://forum.opensourceecology.org/discussion/109/important-about-the-tractor.

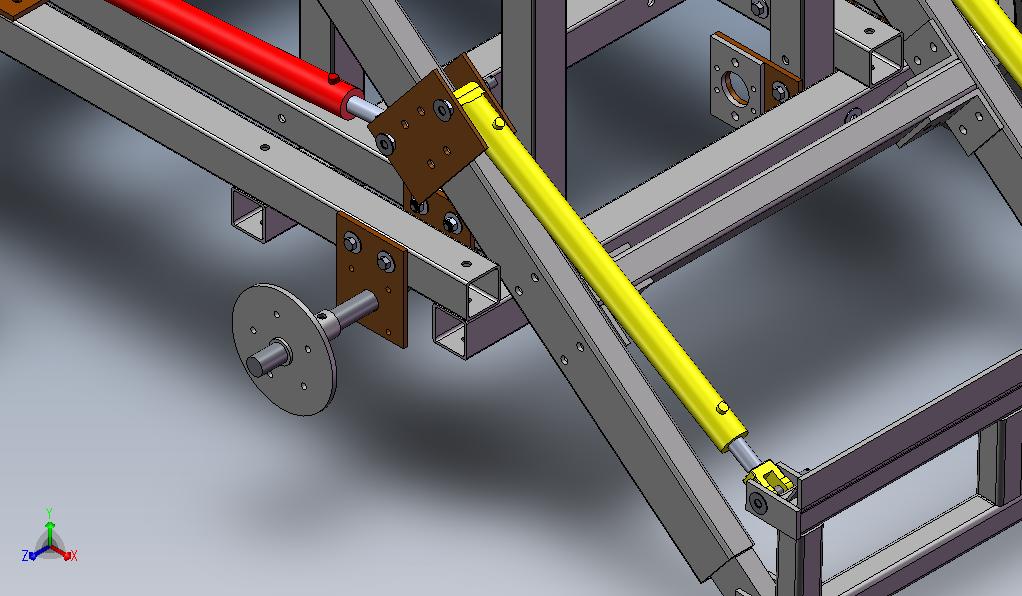

And I attach a pic of the current Lfetrac3 frame design. Anyone in this forum who thinks that's a good way to built a tractor frame???Mike

Attachments

LT3 76inch long (2).jpg 85K -

I think it is both unrealistic and unnecessary to expect perfect designs. I don't really have any expert skills at anything, but I am an aspiring writer, and I think the general notion of writing applies ... so far as I know, not even the best writer produces a perfect, shiny draft the first time. The aim is to complete a draft, then go through and fix the problems, beef up areas or rewrite things that aren't working.It is my impression that open source software, Linux being a great example, goes through a similar process. I know there are a lot of Linux fans out there ... but how many of today's Linux users leapt in when the very first version of Linux was first being developed? Its my impression it was a small, hobbyist group and Linux has only risen to its current prevalence from major improvements over its first release in available software and the interface (such as a GUI).I am not the most overly optimistic person. It is difficult for me to imagine Factor E Farm with however many people it has the means to accomodate onsite (10 units plus however many are currently onsite), even with a nuclear physicist, could churn out a working prototype every other week.All aspects are important. I (as a non-expert on anything) think organization is probably one of the most important things to develop right now ... you don't necessarily need one team for every project, but certainly some amount of parallel teams would be good ... five or ten teams could alleviate the one-team-needs-to-do-it-all issue. It would be great to have experts experienced at machining, or at least using the commercial equivalents to each of the 50 GVCS machines who have a solid understanding of what the machines need to do, and could scratch together a working model to accomplish this.I think progress reports and videos are also a very essential element ... undoubtedly every prototyping will encounter problems, roadblocks and sometimes find they've been racing down a dead-end path and will have to scrap part of what they are working on. With progress reports, teams could learn from each others' problems and hopefully avoid them, enabling experience-through-trying to be, at least to a degree, shared, hopefully reducing some roadblocks and dead-ends as teams learn from each other. The machines may be very different, but there are some commonalities and common issues that, if learned from once encountered, can be shared with other teams so those other teams can avoid repeating the same mistakes.

-

@Howard_V_Agnew

I don't think I expect perfect designs. But I expect working quality designs !

The written OSE specifications demand industrial efficiency (#9), high performance (#8) and lifetime design (#13). It's sad but until now noone could convince me that current OSE designs fulfill those criteria.

Let's see the lifetrack. In the thread I have cited above, there has been a lot of critics stated about the current design. And for me is obviously that many mentioned points are really weaknesses of the current design.

Dawk has very precisely put his finger on the weak points of Lifetrac. The result is - nothing !

Another OSE specification calls for proven techniques. Is Lifetrac3 proven techniques?

I don't see that. There are 2 concepts for tractors in common use today:

- front-steered 4-wheel tractors with rear or 4WD

- articulated tractors with 4WD

Is there any good reason the OSE management believes a skid-steer tractor with tracks could be superior?

If the concept is already wrong, there won't be much improvement by later versions.....

Howard, You have made a comparison with the development of LINUX. Okay, but I see 2 big differences. Linux based on proven technology - Unix. In fact it is Unix, there were just some legal aspects they couldn't name Linux as Unix.

But the most important difference is between open software and open hardware like a machine !

Upgrading an open source operating system to a new version cost just one thing - time. Time for which the developers of linux were not paid at all. Upgrading an mechanical design of a machine is much more expensive, You need new raw materials, components, wear an tools for machining etc. I doubt if OSE can afford to produce 15 upgrades of the Lifetrac.

There is another big difference regarding upgrades by the end user. Upgrading software requires downloading and installing only. Upgrading hardware requires purchase of parts and an typically difficult disassembling and reassembling of your machine!

One reason such upgrades aren't available. If You own an John Deere 7920 tractor, You can't buy an upgrade to an 7930. John Deere doesn't sell one!

Even if they would sell one, I doubt if many farmers would buy and install such an upgrade??? The reason is fairly simple:

A farmer bought his 7920 5 years ago and used it already 6000 hours. Now he can buy an upgrade to make an 7930 out of his 7920. Why should he spent a lot of money and time for that upgrade?

If he does, he has an 7930 but with many components already worn out. Remember,a tractor has typically a useful life of 10,000 or 12,000 hours!

That is the reason why I consider development and upgrades much more critical for hardware like machines than for software

Mike -

@Bastelmike -I am going on thinking alone here, but I think analogies apply. OSE are able to accomplish much, and I think you and a lot of folk dismiss OSE too readily because they aren't starting completely from scratch and finding ways to magically conjure everything they need from the sun and soil. As a matter of practicality, they have to use what's presently available to start ... tools and materials that must be bought from today's suppliers, to develop the first models of the machine prototypes. Yes, that costs money, but between selling what they are already able to build (the LifeTrac and the CEB), and donations from TrueFans, they are able to sustain their development operations. They are able to build and sell the LifeTrac and CEB at a profit, and still sell it for far less than tradiational commercial factory-produced equivelants.The parts they use to build the machines are cheap, very cheap compared with the parts to fix, say, a John Deere or Kubota tractor.The machines they are designing are based on existing machines ... tractors have been around for a long time. Linux didn't copy Unix code; that would have sunk Linux very quickly to copyright lawyers. Torvalds and the other developers merely used Unix interface standards which made Linux compatible with UNIX. The Linux "engine" -- the OS kernel -- was coded from scratch; they did not copy one line of Unix source code (again, it would have been illegal for them to do so). The various components, coded from scratch, had to carry out the same functions as the UNIX equivalents. The early development iterations of Linux were very crude and rudimentary ... doesn't that sound a lot like how you describe the early working prototypes of OSE's GVCS machines? The capability goals of exceeding capabilities and efficiencies of commercial equivelants are just that -- goals. They aren't there yet, and its not reasonable to expect them to be while they are still prototyping initial versions of the machines.The OSE team at Factor e Farm will continue to improve the designs, but part of the idea of open source design is that when other technically capable people and teams start working with the design, they are able to make improvements. The Factor e Farm team get the designs started, but the rest of the world when those designs are ready to be adopted and built independently will be able to collaborate and make the designs really shine, just as happened with Linux as more and more hobbyists used Linux and programmers all around the world, more and more, poked through the code of the Linux OS and were able to make improvements here and there. Torvalds lit the match of Linux, but he did so knowing Linux would only realize its potential if he became just one of many programmers working on it.Development and upgrades will continue, of course, at Factor e Farm, but it won't be until a healthy number of other OSE based communities have the full working blueprints (which aren't there yet, even for the CEB and Lifetrac; I hope to be part of the team to help work on those ... but writing the technical documentation comes after they have a bug-free design, just as its rather pointless to try to start writing a user manual for software before the software is past the point of major revisions and design changes for its initial release version) and building their own machines and can spot ways to improve the design. Linux is being ever-refined, and when the GVCS is launched and communities are working on building the machines, the success of open source for software will be realized in the GVCS open source hardware.People can upgrade their John Deere tractors. Mechanically inclined tractor owners have been doing so for a long time, just as people soup up their cars. Its not fully equivelant to the GVCS, though, because parts for GVCS machines will be cheap (and when a community has a full set of GVCS, they will be able to make their own parts themselves, making the parts to repair or upgrade to a newer hardware version even cheaper and costing mostly just time to do).Unlike commercial tractors and machines, the GVCS is being made with modularity in mind. The Power Cube, for instance, would be the engine to power a lot of the machines. If a Power Cube breaks down, all they have to do is pull it out and replace it ... if they need more power and a newer Power Cube is available (or one that uses fuel that is cheaper or -- such as with biodiesel -- could be made on-site instead of bought), they can swap it in because the dimensions of the PowerCube and connections (the 'interface') are made to be kept standard.Commercial tractor and vehicle manufacturers do not do this with their products. Year after year, they re-design everything and user serviceability is not a priority for them (while it very much is for the GVCS). The commercial manufacturers are driven by a lust for profit ... in fact, when a company like a commercial tractor manufacturer lists itself on a stock exchange like Wall Street, they make themselves dependent on being greedy and shorting their own employees and customers in terms of paying their workers fairly and making their products serviceable for their customers over a long run when they break down or become obsolete. They sex up "the all-new, improved" new-year model as the best thing ever, putting a facade on their greedy slyness and making consumers believe its actually a good thing, and you should just throw away your model from last year and fork over a huge amount of money to buy the new one.Before all 50 machines are prototyped, the LifeTrac and CEB will undoubtedly go through a number of improvements ... but I think most folk in OSE readily expect they will only reach their true potentials when people start building them worldwide, and every builder can spot even a small thing in the designs that can be improved. It won't be a team of 10 or 20, then, but hundreds, thousands, potentially eventually millions of builders, each of whom has a set of eyes and a brain and greatly improves the odds of finding a design improvement, sharing what they've found and the improvement getting worked in to the official design blueprints. The development of the machines will never end, just as the development of Linux will never end. The LifeTrac and CEB are in early, rough stages, but they're complete and functional to the point Factor e Farm can build them, and they've found customers to buy them which helps fund further development on them and, most importantly, the other machines in the GVCS.

-

@Howard_V_Agnew

That may be true for open source software, as the documentation always tends to lag behind the development, but for open source hardware, no one can contribute to the effort if the "source code" as it were, isn't readily available.

A "users manual" isn't what is sorely missing, but rather ongoing plans of what is being built, and how. What is or has been revised, and why? This tends to be shrouded in mystery with the current setup, and the world at large, in addition to the majority of monetary contributors don't even find out about the iterations until long after the money was spent (often on something or in a direction that would seem not to hold up well to open peer review after it comes to light?). There doesn't really seem to be much "Open" in the current state of OSE.

I was somewhat confused by some of the recent video updates from Marcin, regarding problems with the supply chain of getting some parts. Specifically, the circuit boards for the controllers for the CEB presses they are trying to fabricate now, and it seemed to me that this shouldn't have been (much of) a problem, because if this was truly open source, I could have just downloaded the files for these missing circuit boards, and then made 3-4 of them in my basement, and dropped them into the mail to them. I couldn't find any such details of how to make the missing boards, even if I could have produced them in less than 2 hours in my basement with what I'm already set up to produce...

Furthermore, although I've got some major issues with the inclusion of the microCNC circuit board milling, as even being included in the GVCS 50, (I make boards via chemical processes) the wiki pages clearly show a possible small-scale cnc mill that should have been capable of making those missing boards with an estimated cost of $100 to build.

Why, if this is supposed to be an urgent need that has now held up a production line, hasn't someone just built one of those $100 systems to make the boards they were lacking? Surely, it couldn't be for the lack of the $100, even if that cnc mill was limited so that it didn't scale well enough to build all of their future planned boards for taking over the world, the cost would have amortized itself quickly enough to make it well worth the expenditure, right? Or perhaps not?

I then stepped back and looked much harder at the entire GVCS 50 set, and deduced that inclusion in that set seems to be arbitrary, and very subjective, but based not on what existing technology is out there, but rather on what they'd like to be out there, and also what is already well published, even if it didn't suit the OSE goals. Having some YouTube videos of your hobby project and a website for it lends credibility for using your methods, even if you're openly admitting the limitations of what your project can't do, vs. examining the existing projects and evaluating them for their advantages & disadvantages, and then choosing a project based on standing on the shoulders of the pre-existing work to do better (while actually meeting the goals of OSE) vs. just trying to re-use/duplicate existing projects, warts and all.

There are some major gaps in the choice of the GVCS 50, & I don't know if these are because the folks responsible for making that list are just blind to those gaps, or because they didn't find existing projects on the web that others were already doing, or they are so far outside of their interest areas that it is completely off of their radar, or ??? My wife pointed out that "recreating a comfortable modern lifestyle" will also require textiles (cloth), a sewing machine, and refrigeration... Who knows what else is a major blind spot on the list? She also went on to say that rather than review and critique the OSE list, it might be much more productive to make up her own list independently, and then compare the two. Not sure if anything would come from that, as I think the mechanism for input of ideas from us "outsiders" is really not clear, if in fact we even have a voice in the projects at all. It sure doesn't feel like we do, and this forum often seems just a place to blow off steam, with no real effect on OSE at all (unless we were to go off on our own, and make our own projects, publish them to the web, and garner the attention of the Maker Faire, MIT, etc., then OSE seems likely to accept input from our suggestions, but barring that???)

Anyway, my point is mostly that is has been rather impossible for us not located at FeF, to participate in the development process, because there is often not enough information available for us to even try to replicate it from afar, let alone improve on anything.

-

I'm not at FeF, regrettably, but I hope to be. My general gist of things at the moment is don't worry; no, nothing is at the goal yet, not even for the LifeTrac nor the CEB, but they are making steady progress.The gist of what I've seen so far, in throwing my name in to join FeF possibly for documentation, is that it has been readily admitted the documentation is a bigger workload than had been anticipated and it (getting documentation done) isn't going as well as they had hoped. I infer that it has been more or less declared an area of weakness, one they are going to take pains to address by bringing in one or more people experienced with CAD and technical writing to FeF to hammer away at. Unfortunately, I seem to be the least experienced of the others who have thrown their name into the FeF, especially at CAD, but I still help for a chance to help out. Short of that, I can certainly try to review, revise and edit the wiki articles where I see typographical, grammar or word choice flaws and am kicking myself in my lazy butt to do so.If you have solid working plans for creating the circuit boards, or whatever, I can't imagine anyone (though the only one I know personally on the crew so far is David Ihnen) would get mad if you put together working blueprints and instructions for doing so and putting them forward to be used. If you could use a technical writing novice to help with such documentation and instructions, I readily volunteer to help you with that unless/until I get called to dig in at FeF ... unless/until I get onsite to FeF, I have no job and few obligations to stand in my way, and would love a chance to sharpen my skills and donate my time to helping you help OSE if you have knowledge that can be made into working plans and instructions that would help get more bang out of FeF's time and material bucks.Open source, I think, benefits from criticism of what's being done as much as new ideas, but I would ask to proverbially step back a bit if you feel the whole thing is wrong because the early development prototypes fall far short of the promise. I couldn't comment on the completeness of the GVCS, but I wouldn't be surprised if it goes through changes as they go through prototyping the tools, but the GVCS as a whole I don't think anyone can know for certain if it is adequate until all the prototypes are completed and deployed together to see whether they work as well together as intended and truly do allow a community to be completely self-sufficient, or if there are gaps or redundancies that would best be dealt with adding machines to the GVCS or replacing current ones. I absolutely must qualify my "thinks" as being non-expert, but in general I think getting the stuff working is the most important thing right now, getting it working well shouldn't be fretted about too much until after every machine in the current GVCS is developed and complete.

-

> There are some major gaps in the choice of the GVCS 50

This topic has been discussed repeatedly on the OSE forums and elsewhere. Previously, it was the GVCS-40, but there was a bit of inflation. Regardless, Marcin has frozen the current selection of 50 tools/technologies. He has indicated that it will be open for new suggestions once the current 50 have been developed. Unfortunately, that might take longer than next year.

> My wife pointed out that "recreating a comfortable modern lifestyle"

will also require textiles (cloth), a sewing machine, and refrigeration.

All of these have been pointed out, previously. My pet missing tool is a micro-hydro system. They have all of the other alternative energy sources in there, but missed water. Sigh.

> I think the mechanism for input of ideas from us "outsiders" is really

not clear, if in fact we even have a voice in the projects at all.

There is no mechanism for proposing new ideas because the list is frozen. However, people are free to add ideas and suggestions to the wiki for possible consideration at some later (and unknown) date.

> this forum often seems just a place to blow off steam, with no real effect on OSE at all

Well, there has been some meaningful discussion on the forums, but I'm fairly confident that Marcin no longer reads the forum entries, much less respond to them. There was some considerable debate a while back about locking the forums down and severely restricting their use. It was never implemented because, as you suspect, it is largely ignored. I find it useful, however. You may also. I wouldn't view it as a means to influence the direction of OSE, however.

> unless we were to go off on our own, and make our own projects, publish

them to the web, and garner the attention of the Maker Faire, MIT, etc.,

Others are doing just that. There are several sites that I am aware of started by disaffected OSE participants. I have my own site, for example, at https://sites.google.com/site/phase3project/ started largely because there were things that OSE just didn't want to devote time or money to.

> my point is mostly that is has been rather impossible for us not located

at FeF, to participate in the development process, because there is

often not enough information available for us to even try to replicate

it from afar, let alone improve on anything.

Attempts at distributed development work have not gone well, as far as OSE is concerned. My understanding is that bring them under one roof at FeF is the preferred development strategy, in spite of announced intentions to pursue "massively parallel development efforts". So if you feel out of the loop, it's not really a complete coincidence.

I reached the point you are at several months ago, Allen. I'm more or less resigned to OSE going in the direction that Marcin wants it to and on most levels, that's ok. It is his project and if he wants to run it this way, it is his choice. We have the option of participating or not, contributing or not, funding or not. Many people have come and gone over the years. Personally, I think that some changes would greatly improve progress and quality, but those suggestions have not been taken. Meanwhile, I'm very curious to see what OSE can accomplish using this approach. This is not a complete waste of time and money, Allen. Some things are coming out of it. Even if we get a great example of what NOT to build, it was worth doing.

- Mark

-

@Howard

I am going on thinking alone here, but I think analogies apply. OSE are able to accomplish much, and I think you and a lot of folk dismiss OSE too readily because they aren't starting completely from scratch and finding ways to magically conjure everything they need from the sun and soil. As a matter of practicality, they have to use what's presently available to start ...This seems to be an missunderstanding! I didn't critisize OSE for using to many bought tools and materials, just the opposite. They haven't bought a real metalshop with standard equipment, and that influences their designs. In a very negative way, by simplifying them until loosing their useability!

They are able to build and sell the LifeTrac and CEB at a profit, and still sell it for far less than tradiational commercial factory-produced equivelants.

Maybe there are regions in the world where they really can sell a Lifetrac. Hard to imagine. But in Europe, You won't sell it! Because of the farm structure, farmers need to operate their tractors on road, and they are used for road transports with trailers too. But You will never get a road permission for a Livetrac3 with skidsteering, tracks, no independent brakes.... In fact, I think it can not be used in most countries of the world where farmers live in villages and there are at least some regulations for road vehicles. So chances to sell it are pure

The machines they are designing are based on existing machines ... tractors have been around for a long time.

OSEs design of a tractor has nearly no parallels with existing tractors, neither today built nor built 50 years ago. Tractors are built the way they are built today because that has been the evolution of tractor design - no need for OSE to spin the wheel 100 years back and try again from scratch.

There are obviously other reasons why the OSE tractor looks as the Lifetrac3 now:

There were no experienced designers to design engines, clutches, gearboxes, axles etc.

There were no foundry, no precision machine tools available to build these components

There also were no skilled machinists and mechanics, welders to fabricate a more complicated but superior design.Thats why we are stuck with a Lifetrac3-design, Howard As mjn wrote, practicality rules !!!! A sentence that doesn't need more comments

Mike -

@Batelmike

My understanding is that the shift from a transmission/cluch drive train to one based on hydraulic motors was a deliberate design choice to simplify things. Direct drive motors are common on electric cars, for example.

> There were no experienced designers to design engines, clutches, gearboxes, axles etc.

Engines are on the list for fabrication down the line. If transmissions, etc. are needed, they will be added too.

> There were no foundry, no precision machine tools available to build these components

FeF has some precision tools, but certainly not foundry capability. We need an induction furnace for that. How hard could it be? :)

> There also were no skilled machinists and mechanics, welders to fabricate a more complicated but superior design.

There have been a few folks who stayed at FeF that could be considered skilled machinists and mechanics. However, they don't stay there forever and there is considerable turn over in personnel there. Thing is, Marcin (et al) think that the existing LifeTrac IS a superior design. However, that opinion hasn't really been proven out yet. The LifeTrac needs more field trials - at the very least.

It could be that the LifeTrac is mis-classified as a tractor. Because of it's skid steering and metal treads, it's closer to a bulldozer, though under powered for that. I suspect that such vehicles are not allowed on European roads, either.

- Mark

-

Howard, I applaud your recent flurry of efforts to improve the documentation of this movement. Thank you, no matter what the results turn out to be.

As far as documenting the chemical methods of etching circuit boards, it would seem much like re-inventing the wheel, at least to anyone who has done it, because there is already so much material available on the web to show one how to go about doing such, if there is inclination to do so.

I was rather perplexed by my inability to locate the video I saw, where Marcin was giving an update, and commenting about being vulnerable to Global Supply Chain problems, while pointing to a pickup truck bed full of 5-gallon pails of hydraulic fluid, which had risen in price substantially from the last time he'd bought it. It may be that that video has been removed/deleted, since I saw it, but I can't find it anywhere now.

In that same video, he'd commented on a production delay because of the lack of this board: http://opensourceecology.org/wiki/File:Driverboard.jpg and although that pic is still part of the controller box wiki page, they've apparently reverted to their older design, which used a pair of smaller boards that are more readily available. He did specifically ask if anyone could/would send him 3 of those

boards, though I don't know how serious he was. (I then tried to locate

some mask files for the board to print out 3-4 of them to send)

All traces of the links to buy that board seem to also have been removed from the wiki & the history too??, although rather than subscribe to any conspiracy theory, it makes more sense that the documentation is being revised to reflect what they are doing, and feel they can sustain, not due to any malicious intent, and in the grand scheme of things, it probably doesn't matter enough to care about.

My concern was that if this part is or was included in the system, it should have had enough information available from the site or some site to accurately reproduce it, which this "custom" board was lacking. The other boards from the previous design revision, even though they are still being sourced commercially, are open source enough that one could download the design files for the boards, and make them from scratch, if desired.

http://opensourceecology.org/wiki/CEB_Press/Manufacturing_Instructions/Controller_Box is the page in question, fyi, and the commercial part is shown to be available here: http://store.makerbot.com/pwm-driver-v1-1-kit.html, with detailed files to build it and/make it yourself here, including a sourceforge download to the board layout files: http://www.reprap.org/wiki/PWM_Driver_1_1

I don't understand how a production line that ytd, has netted $25K, could or should be held up by the lack of $100 in machinery to make critical parts is acceptable, and fwiw, there is no guarantee that the other boards won't be out of stock at some point down the road, or for that matter, the arduino boards themselves could be out of stock, but with the plans available...

I think I am probably echoing BastelMike's points that OSE isn't making good or full use of the resources that already exist to go forward more efficiently, and we get to sit on the sidelines and groan, while pulling out our hair over things we see that just don't make sense in the real world. I am a small business owner, and I can't justify the lack of a $3K part or machine that might jeopardize a $25K account or revenue stream, even if that $3K machine wasn't fully "Open Source" (The $100 machine isn't open source, just cheap, & good enough to get by).

If you really wish to add to this project wiki information regarding chemical etching of circuit boards, I will support that as best I can, although I don't know how to add to the wiki, I can certainly feed you information that is relevant, and also I can even share my real-world results, along with some pics, if needed.

-

Thank you for the gratitude. :)Not being there personally, I couldn't speak specifically, but how much of a business could you run if your gross revenue was $25k over nine months and you had to buy food to feed your crew and buy all the parts and materials to make what they've made thus far, including hiring the bulldozer to clear grounds for the new Hab Lab as well as the materials to build the hab lab (and the parts for their new dimensional sawmill).I've rehashed my earlier responses on the practical reality at the FeF into an incoherent video (I really don't speak well in public and am trying to overcome camera shyness) ... http://youtu.be/RM4Zs-nwRlk

-

I'm pretty sure that the $25K wasn't the gross revenue in total, but rather just the net proceeds from the sales of production. There is also income from monthly donations and grants, which handle the day-to-day operational costs, and any product line that had a net profit of $25K should surely be worthy of spending a few grand to protect the supply chain of it.

Since such an investment isn't a throwaway investment, but rather something that has a useful service life that can be measured in possibly a few more seasons of production at minimum, its costs can get amortized even further over a much wider range of production runs, and the cost per unit goes down even further (not to mention the production efficiencies gained by not losing the down-time waiting for 3rd-party parts that could be held up by acts of God, labor conflicts, etc.)

Shortening one's supply chain always leads to opportunity for greater security & control over one's destiny.

-

mjn-

My understanding is that the shift from a transmission/cluch drive train to one based on hydraulic motors was a deliberate design choice to simplify things. Direct drive motors are common on electric cars, for example.

OSE and FeF keep on simplifying. Complete simplification of a tractor design will end up with a thing people commonly refer to as a hoe :-))

Using hydrostatic transmission isn't the major design flaw in the Lifetrac design.

It's no new idea, IHC built some tractor models with it in the 70s and 80s. They were not sold well and since then farmers and engineers in general believe that powershifts and CVTs are superior to hydrostatic in tractors.

Remember, direct drive motors, electric or hydraulic, are able to operate with widely variable speed, but they can't deliver improved torque at lower speeds.

Maybe You know that good CNC machine tools with EVS for the main spindle have 2 or 3 mechanical steps; just to provide enough torque at the spindle at lower rpms

FeF has some precision tools, but certainly not foundry capability. We need an induction furnace for that. How hard could it be? :-)

As far as the descriptions in the wiki are correct, they seem to have a lathe (used). No other real machine tools seem to be available, or they are kept secret.

Mark, You prob already know that I very often have a different opinion than that of OSE. Not to provocate, it's just that my knowledge from my study or my experience

tell me to better use another approach. Just a question first: Who of You has ever worked for a minimum of several weeks in a foundry?

During my study I had to for one month, so I got a basic knowledge about castings and foundrys.

Is an induction furnace the right choice ???

It's a clean technology, for the community and the molten metal. It's able to melt steel ! And I don't think it's to complicate to build one for OSE.

My reservations come from the electric power requirements they have. For large machine parts as bulldozers, steel rollers, large machine tools the OSE set will need castings of several tons. To melt 5 tons in an induction furnace You need an electric power of 500-1000 kW. Arc furnaces have similar power requirements!

The small foundry I have worked for could cast iron parts of 3 tons. With an old furnace, gas fired, it was a killn design, don't know the correct word in english (german Drehtrommelofen).

I think something like this furnace is easier to implement than a large induction furnace. Can you imagine operating a 1000kW furnace in Africa - they have blackouts nearly daily without this....

If OSE wants an induction furnace, it will either be very small or the power requirements will be too high for replication in many places in the world. OSE plans to build an 50kW wind turbine, you will need 20 of them for one foundry, with optimum wind conditions....It could be that the LifeTrac is mis-classified as a tractor. Because of it's skid steering and metal treads, it's closer to a bulldozer, though under powered for that. I suspect that such vehicles are not allowed on European roads, either

I guess it might be useful as a front-end-loader in construction. As a bulldozer it's not only under powered, but under weight too.

Several weeks ago I read an article about destumping, removing tree stumps. They stated that a bulldozer of minimum 10 tons should be used, in difficult conditions 15 tons were desirable. -

There is a Bulldozer in the GVCS set. I noticed the GVCS chart seemed to recently update the bulldozer into the purple "Prototyping" status (above the regular white and cyan "Development" stage).

-

(BTW, BastelMike, the furnace you mentioned is a rotary furnace, similar to a cement pug mill)

There are many things in the GVCS set that don't add up to known reality or laws of physics, which is somewhat surprising, considering Marcin's background as a physics PhD.

For instance, that 50 KWh wind turbine is questionable, working backward from the available data.

FeF is located in an area that the National Renewable Energy Laboratory (NREL) classifies as a Class 2 wind power area. (See http://rredc.nrel.gov/wind/pubs/atlas/maps/chap3/3-44m.html for Missouri windpower map.) They don't even recommend anything below a Class 3 as feasible for windpower generation, but that's another issue.

Class 2 wind power means an average wind speed of 9.8-11.5 Mph at a height of 33 ft. & 12.5-14.3 Mph at a height of 164 ft. See http://rredc.nrel.gov/wind/pubs/atlas/tables/A-8T.html for the full windpower classification chart (It shows metric values also)

First, assuming that FeF can manage to fabricate a structurally sound tower capable of withstanding the elements and other forces applied to it that is 164 ft tall, they can get up into the higher energy air flows.

Working backwards from the power rating of 50 KWh is somewhat confusing, because the Windpower industry (which is trying to sell you on their garbage) will always rate their products by the peak power output, not the real-world typical output at a given location. By this method, one shouldn't expect to get more than 1/10th of the peak power from such a device in real-world application, on average. Since we would actually NEED 50 KWh+, I'll use that as a target for further calculations, even though it will describe what the wind power industry would sell as a "500 KWh" wind turbine.

To get 50 KWh of energy from a wind turbine, in an air flow of 13 Mph, it would have to have at least 84.3 KWh of energy in that air stream IF the turbine was at it's theoretical maximum efficiency of 59.3%, according to Betz' law (http://en.wikipedia.org/wiki/Betz%27_law), but since we would also have other inefficiencies in the system & we can't expect our FeF-built turbine to be theoretically perfect, we should plan on capturing from a stream of at least 100 KWh, as a 35% efficiency is more realistic (with very good design!).

Maximum energy in an undisturbed stream of air is determined mathematically to be:

E = 0.5 * ρ * V3*(cross-sectional area)

where ρ = the density of air, or 0.00237 lbf * sec2/ft3, give or take, depending on the barometric pressure, etc. & lbf is the Imperial measurement of pounds of force to distinguish it from pounds of mass/weight, and is in units of lbs(mass)*ft/sec2

We know that E has to be equal to 100 KWh, and we also know that V is going to be nominally about 13 Mph, or about 19 ft/sec, we can solve for the needed cross-sectional area of the turbine we'd need to be building at FeF.

13 Mph = (13 * 5280 ft/mile = 68640 ft/hr)/3600 sec/hr = 19.067 ft/sec

100 Kilowatt-hours ≈ 4425372.896 ft-lbf/min which when divided by 60 converts to 73756.21493 ft-lbf/sec

73756.21493 ft-lbf/sec = 0.5*(0.00237 lbf-sec-sec/ft-ft-ft)*(Vcubed=6931.45363 ft/sec)*(area ft-ft.)

Solving for area = (73756.21493 ft-lbf/sec * 2) divided by the quantity of [(0.00237 lbf-sec-sec/ft-ft-ft) * (Vcubed=6931.45363 ft/sec)], or 8979.57844 sq. ft.

For a circular (horizontal-axis) wind turbine, this comes out to a single blade length of about 53 ft 5.5 inches, and a diameter of twice that, or about 107 ft. Given that FeF has shown a propensity for non-engineering to the degree that in the OSE lathe discussions, an experienced machinist commented that he didn't want to be anywhere near their lathe design if they should ever apply 20 hp input to it, and it only had a rotational diameter of something like 9 inches, I shudder to think about a piece of heavy rotational machinery with a diameter of 107 ft turning up in the air 164 ft up would do if they should get it there...

They're not likely to get 1000 KWh of power for their induction furnace, even on a farm where they have no governmental oversight to prevent them from trying something unsafe, let alone produce something like that which could be duplicated around the world without a great deal more experienced engineers and fabricators/machinists in any manner that could remotely be considered to be safe.

-

@BastelMike

> Just a question first: Who of You has ever worked for a minimum of several weeks in a foundry?

I have never worked with molten steel. However, I have experience as a blacksmith with hot iron. The only cast experience I have is with lead into toy soldier molds. Perhaps that gives me the ability to speculate, but I certainly wouldn't call it expertise of any kind. OTOH, I have a friend who was the supervisor for a production-level induction furnace for more than a year. He has examined the OSE induction furnace requirements and made pretty much the same observations: energy is the critical factor. The furnace can be built, but powering will be very difficult.

- Mark

-

DavidIAm, just on the surface, one will need much more than 300 horsepower to run a furnace that required 1000 KWh, because even if you had 100% conversion efficiencies, 1000 KWh translates to just over 1341 horsepower.

This doesn't mean that it is not possible, but rather that you won't get there with a standard Detroit Series 60 6-71 ;)

Due to losses in conversion, etc., mechanically generating power will probably be much worse, because the adiabatic efficiency of internal combustion engines is generally quite poor overall, unless you were able to use the waste heat for something useful also. It is probably not practical to expect efficiencies of more that 30%, with steam or diesel power, but that just means you'd need that much more of it.

The largest capacity generator head I can find on a quick search of off-the-shelf products is a 325 KW (continuous) generator, and it requires 650 hp as an input to produce that. It is also about $11K, give or take. Since it would still require a power source, it might be more practical to look at commercial/industrial gensets in the short-term ($50K for a 311 KW genset), and for the long-term, a much larger scale power station.

This is something that would require land & insolation on par with White Cliffs, to be effective, although it is possible that OSE could work on storage of electrical power, and then run in batches after recharging batteries.

Bringing it back to the topic of the thread, IMO, OSE will need to do a few things to get anywhere close to their GVCS-50, one of which being identifying the low-hanging fruit, and just get that out of the way asap. That way, it can be commercially available to help support the remainder of the R&D, and also, they will need to revise the list to separate out the unobtainium from the obtainium.

It would be refreshing to see OSE get back to the roots of what is needed to provide a comfortable lifestyle for human habitation, starting with things like food, shelter, (clothing??), and work up from there, because it will be much easier to attract developers/fabricators/engineers/etc., if they weren't required to go on extended camping trips to participate (& still be responsible for providing for their own food/shelter/water/etc.)

Another thing I'd really like to see, is the elimination of the well drilling rig from the GVCS 50, since humankind is already rapidly depleting the aquifers as it is, & if Mike Reynolds (http://www.earthship.com/) can make a desert climate that produces only 7 inches of rain a year support a comfortable lifestyle with rainwater harvesting, surely water harvesting in a non-desert climate, is a more practical approach to providing water than digging another well... OSE doesn't need to be wasting resources re-inventing wheels that others have already rounded out & published their results.

-

I'm no expert myself, but my strategic guess would be production machines like the torch table should be an early priority, as I think it would help cut down on prototype development time for the other machines.

-

I agree, and had corresponded with Marcin directly on it in the past, but they seemed to have gotten hung up on trying to make the torch table a larger sized version of a RepRap, and couldn't see their way clear to abandon the stepper motors, so I gave up trying to advise... That's been maybe over a year since then.

They seemed so inclined to stay with the stepper motor design, even though they couldn't come up with an Open Source stepper motor driver powerful enough to drive the torch table, and the project seems to have just stalled since then. I had told Marcin that they should switch to servos, and even point to both the existing open source motor controller project that is robust enough to be used by the US military, and the open source servo controller, which is also mature, but would require some minor adapting (it was developed mainly for radio-controlled servos on model planes), but the available electronics would work on any DC servo.

I had also pointed out that to scale up to any serious CNC, they would eventually need to switch to servos, because steppers were just too sloppy and imprecise. I don't think they've come around to that yet, but I'm sure that they will eventually have to admit to it and change the designs. Servos can give precision repeatability to thousandths of tolerance, where steppers have no feedback, and are lucky to give 1/16th of an inch tolerance, so instead of trying to scale up a toy plastic extruder, where the tolerances didn't really matter much, they could start with a design that would scale up to handle even their multi-machine and beyond, when they were ready for it.

-

Not so serious idea:

How about aquiring an old diesel locomotive? They have generators already and they are 1500hp and upMike

-

Howard_V_Agnew

I'm no expert myself, but my strategic guess would be production machines like the torch table should be an early priority, as I think it would help cut down on prototype development time for the other machinesOh no, Howard please not!

This will end up with OSE and FeF developing only a few machine tools the next years. Machine tools, that will be inferior in design, stability, feed and speed range and operator comfort to commercial machines. And their precision will be lower than industry standard too, so second-hand bought machines with some wear will probably be equally precise than OSE tools, if not even better

Sorry Howard, but the level of engineering science shown by FeF until today isn't that sophisticated. Maybe they have excellent designs ready and are not showing them yet, but else...I miss the needed level of professionalism in machinery fabrication by OSE! Starting with the sketches of the OSE shop!

Who in the world builds a machine shop for large products with poles 16' apart?

There are "open-source" designs for shops available in the web. Just google for DIY farm buildings or similar. You can get complete designs for pole-buildings with span of 30', 40' 50' and more. They make a better room for assembling tractors and bulldozers for sure.And why not look for a basic production set on the used machinery market now. I'm pretty sure the funds for some used tool machines would be available; as soon as they have them they could start to effectively produce machinery at FeF to regenerate their funds:

- a small lathe 16"x40"

- a large lathe lets say 30"x100"

- a Bridgeport type mill

- a larger bed-type mill with CNC, say table 100"x40"

- a small cylindrical grinder

- a powerful bandsawWith such an set of used equipment they could economically produce the designs that are finished and a shop with this equipment would form a better basis to develop the missing 45 machines.

But Im afraid that FeF will continue as before, they maybe believe that they everything the optimum way. They don't want external advice, no subject matter experts. So we will have to just look for the outcome....

Mike

-

Mike: my thoughts exactly re the not wanting help. It is clear from several different angles that the inner circle of people just are not interested in contributions coming in over the internet. It's a foolish and wasteful attitude, they could get a dozen skilled people for every one at FeF if they played their cards right, helping with where they need it the most: design, planning, wiki and other office type work, etc. And to play their cards right they need only to listen to people who are telling them how.

Whatever, if they want to be that arrogant they can wallow in it. It will take years and years to complete the GVCS and when it is done it will suck because there will simply be very little knowledge and experience behind it.

-

Several of the open source projects in the GVCS have already been completed by other open source groups.

For example the bio gasifier has been undertaken by the GEK project in Berkley, they are on a second phase of making liquid fuel from biogas, and experimenting with small scale "cat crackers" that are used in oil refineries.

There is a USAID design for a bakery stove using the rocket stove concept.

As for a call for more volunteers, what about enlisting the great numbers of machinist hobbyists at CNC zone, or the Torchmate owners forum. There are threads in those forums already discussing projects similar to this one. With a crowd sourced group of CNC guys, we can advance the quality of the CAD files as well as find subject matter experts.

Torchmate does a lot of sponsorships, what a better symbiotic relationship than supporting a group that is making open source machinery that can be made with their machines?

Regarding power generation, I have had several years experience in the care and feeding of 1 megawatt generators, and they are usually diesels rated at over 1000hp.

One could sync several small generators together to get this power, but that is beyond my skillet.

A more practical method of melting metal would be to use biogas. Victory gasworks has a YouTube demonstration where they melt glass and metal using biogas.

Either way this project ends up here, I still am basing my business model around the production of open source machinery in kit form, and providing CNC plasma cutting services to the local Philippine market. There is a need for this project in the third world.

I have a ton of ideas, just waiting to be put to CAD and built. -

At the farm the time is spent trying to execute designs that have already been created. New design ideas, modifications, and advise simply isn't useful in that context - not without collaboration, discussion, and understanding.We also don't know how to collaborate with remote people effectively. We haven't learned how, we haven't even had the time to try and figure it out.So how do we allow people to help? We know how to talk to peopel who are there. We know how to get face to face and hash things out.How do we learn to collaborate with people who are frequently not available, and not easily interacted with while in an environment like the shop? Particularly when the labor force is critically understaffed, entirely involved in executing something to usability, rather than trying to refine a design?Understand, guys, its not that help is not wanted, or useful. We're learning, its a new way of doing things, and there aren't enough hours in the day to get done what we need to, much less figure out these new ways of communicating. This is hard and tricky stuff.If we have so many skilled people who want to help, what I'd love to see is ideas and patterns that will help the people who want to collaborate be useful. Help us figure out how to produce AND collaborate. Its not obvious or easy. But there are enough smart people out there, it can be figured out, if we put our minds to it.

-

For my part, I'm getting ready to leave for a Dedicated Project Visit. I already have it in mind that I will look for ways that I can collaborate with others who can do some of the work offsite ... it will be a bit easier for me, as my primary task will be documentation. All I will need to do is record the specs for the parts and e-mail them off to CAD team members, so several CAD drawings can then be done in parallel (I can do one, another guy can do one, etc.) Getting the specs and using them to generate a CAD drawing are two big components of doing the documentation. I can well handle actually writing it, though that too will wind up being collaborative, as I share it with the other technical writers who can help sculpt and refine the text.I'm not quite sure how collaboration can work on the prototyping, especially for tackling new builds. Existing builds, when documented, I expect will become collaborative as folk actually start building them far and wide, and that'll be new and fresh sets of perspectives, eyes and brains to conceive of design improvements. I know, then, my job as technical writer will be crucial, as it will open up an avenue for collaboration to refine the finished-to-working-state designs.I wish I could say I have a strong sense of motivation and initiative, but really a good friend of mine ;) suggested I should make myself active, and so I have, and I think I have good things to contribute. I already understand how tight time is, December 2012 is an ambitious deadline for all 50 machines to be complete. I don't know if it is truly achievable, but it certainly won't be if I gave up. Working toward it will get good progress going and build momentum.

-

Come to think of it, anyone with experience in internet collaborations could probably help out by figuring out how to collaborate on pre-documentation prototyping. Lots of use for lots of skills!

-

Well first of all David, your post illustrates that while you'd maybe like help with design, you prioritize it at a negligible level.

Plus actions speak louder than words anyway - the obvious prerequisite for getting people to help with the design of tools is to post the information they need to do their part on the wiki, which is not done.

There are many cases where synchronizing with prototyping on site is not a problem because there is no prototyping happening on site. The steam engine is an obvious example.

For another example, I am learning AutoCAD and might bash out a preliminary concept design when I get time, as an exercise, for a NiFe battery and associated assembly line. But when I realize that you guys have not even made up your minds about what you want yet, never mind bothered to document it effectively on the wiki, there is no point in doing that. And I'm not complaining about me, I am just trying to describe the general situation that people over the internet are seeing, because I'm sure it drives most people off quite promptly. Unlike myself 99% of people will just leave when they see this, and you would be on your own trying to figure out why no one is helping in that way. If you'd ever had colleagues leave you out of the loop on a project in the real world you'd realize that it is a waste of time to try to guess what people want/what is going on.

Chris is saying the plan is to make the casing with 3d printing. The reprap is extremely slow; it would take all day to print a 1kWh battery. Is the goal to sell these batteries in the local economy in any significant quantity or just use them on site?? Plus Marcin has a known habit of not playing by the rules he himself has set out/being unable to make up his mind. There is a difference between being all nimble and willing to change direction, and equivocating ad nauseum. And conversely, failing to do your homework and then being unwilliing to change direction due to momentum when you realize your lack of due dilligence led you to poor decisions, as it probably has on the solar to electric project.

With the steam engine - somebody said something about getting somebody who was on the white cliffs project on the team. What, so is some expert on the case for designing the system now or what? That information should be available, when it is not no one can efficiently contribute.

Actually the steam engine appears to be a fine case of incompetent management on Marcin's part: poor communication, technical inversion (Marcin knows way less than MJN about steam engines at this point, but he is still making and enforcing design decisions), destructive equivocation (MJN comes up with a serviceable design, even right down to the drawings before Marcin changes his mind and throws everything in the trash because he has a desire, which he has never justified in a substantive way, to use the exact same type of engine used at white cliffs as if it is some sort of magic bullet even though it's problems are serious and numerous according to the document itself, and there is no point whatsoever in trying to leverage low cost commodity hardware because the plan is to make the whole thing from scratch anyway.).

Heck, it is not even clear if he wants to use the same or similar design for the biomass burning power generator, and/or the lifetrac. The requirements for the 3 are very different, even fundamentally. High maintenance per hour of run time is fine for the lifetrac, but not for the biomass burner.

In other words things are not ready for outside contributors to help with many of the types of office work that need to be done.

-

Another good apparent example of lack of information that people need to do their jobs, is why Howard has to go all the way over to rural Missouri to get some dimensions coralled up. That makes no sense whatsoever. How can you make something as complex as these tools without having the dimensions written down already? Then just send the raw files to people to go through and produce documentation from. Don't tell me they are flying by the seat of their pants so much they don't even write down their designs.

-

My understanding is that they don't have technical documenters there in the field yet. Marcin has acknowledged the documentation is a bigger task than he has anticipated. There's a lot of stuff for him to keep track of. One guy there who is focused on documentation is, he has realized, crucial to building the informational bridge between the work they are already doing and the rest of the world so others can actually build the machines that they already are. I'm not genius, there's a lot of folk I've seen on the OSE wiki and forums with a lot more experience than I in technical documentation, and I'm not gonna rely on myself.There are specs all over the wiki ... the problem is so few people realize they're out of date. The locations of holes to be punched, even the thickness of the metal differs in their current builds versus the older build specs on the wiki articles. Some parts have been eliminated, others added to shore up the design. Marcin has a kajillion things to keep track of, and from what I've heard the crews often keep working until 2 a.m. or so. It isn't a matter of competency or refusal to cooperate with others, they have a focus on the physical machining and prototyping and don't have anyone there to focus on recording the specs and get the documentation going forward.Its very much a seat of their pants operation. I'm not sure what they're using among themselves to keep track of changes ... they may keep it all in their heads for all I know. Perusing the site, I saw a void in the documentation and I just started picking at it and realized ... hey, I have oodles of time on my hands. I didn't know if someone had already started on the crew and they just weren't going to show it until it was completed, but if I just went ahead and got started pulling together what manufacturing specs and instructions were already on the wiki, at worst I'd be wasting my time re-inventing the wheel. As it turns out, I wasn't ... and my efforts while not yet spouting fruit in the form of an actually completed draft, are definitely showing signs of sprouting and growing.It doesn't surprise nor daunt me at all that they haven't yet been able to thoroughly review a completely different idea for one of the machines. They need more people to free up more time, and that's why there's a huge hustle right now to expand their facilities, including housing for volunteers.I'm finding I need to self-organize, and organize with the existing CADders and machinists like Brianna. The CEB Press documentation is still very fledgeling, but its making progress, and I suspect when I'm able to be there on the ground and can get the specs, not reliant on whatever little spare time Brianna has between her classes and family business and whatnot, it will go faster.I already know going in that I'll have to walk carefully. I must get the specs I need without slowing down or interfering with the actual builds, and that could be challenge since I will need to go through every single part and every single step of the assembly when I myself am just a layperson when it comes to machining. I expect once I have one working draft, updating it for revisions on the prototypes will be a relative snaps ... I hope I can just listen in while modifications are discussed and jot down the relevant changes and get the CAD updated (whether myself or, hopefully, delegate around when there are many parts needing CAD modelling at the same time).I don't want to paint a picture that I'm a genius. I've had nothing but trouble on jobs in the past trying to manage or lead folk ... I suck at it, but I'm hopeful here since everyone who is actually doing work is doing so because they want to. They're not just watching the clock and goofing around for a paycheck ... so I'm hopeful. I wouldn't mind at all if someone else took the management reigns for the documentation and CAD crew, but I think I have a good idea of the task focus I'll need to zero in on when I get to FeF. No one else has really stepped up to it yet, though.That's the way it is, I imagine, with everything. You whine because X or Y isn't being done ... that just means someone needs to do it. Marcin and his crew are, by all accounts I've seen and read, not sitting around sipping champagne and playing World of Warcraft all day long. They're working hard and long hours, all voluntary for no pay. Stuff that isn't getting done, is generally not getting done (as I get the gist of it) because they don't have enough skill in a particular area (like project management and technical documentation) nor man-hours available to do it.

-

Not sure which thread it was in, but I've stated that OSE/FeF has a major labor shortage.

It's kind of a chicken-and-the-egg problem, because they don't have the labor force (or skill sets) to effectively collaborate with & utilize remote labor, nor do they have the management (labor & skill set?) to do so.

I would guess that even if the vast surplus of volunteer labor that is available remotely would suddenly show up at FeF tomorrow, they still wouldn't be able to effectively manage or utilize it, but that is a different topic.