-

111 Comments sorted by

-

Thanks for the advice, but unfortunately that's an order beyond my budget. I am having to get an advance on a friend repaying a loan to me just to afford the fuel to go. I've been out of work for 3 years now and have depleted all of my resources. I do have some digital cameras, but no funds to get extra batteries or memory cards. :( I don't have money for a video camera (my only 'video camera' is a webcam that only works tethered) ... but all of that is secondary to the fact my laptop is cheap, and has proven unable to smoothly handle video editing; it has 3 GB of RAM but only a single-core 1.6 GHz processor. I am presently FINALLY installing Ubuntu on it to hopefully see if it can handle things a bit better than the factory installed Windows, which has gotten slower and slower probably from a combination of bloated "bug patches" and a variety of programs I have downloaded, decided against and uninstalled. Almost all the work I've done so far for the project is with the desktop I am typing this on ... which is too much of a power hog to be able to use on-site.I will have to get myself good steel-toed boots, as my last pair decayed to the point of incurring holes years back when I was working on a dog kennel in the mud. I do find I prefer good solid ear protection ... I had a really good pair of hearing protection ear muffs, but I wound up donating those to my boss at that kennel for whomever was needing to run the equipment to do the yard work. Will need to get myself another pair, I liked them much better than ear plugs.Thank you very much for being a True Fan ... because of my financial dire straits, with zero income aside from a trickle of a friend repaying a loan I issued him just enough for gas to the store and car insurance, I haven't had the means of donating money. I know a lot of True Friends donate time and money, and unfortunately money is needed in abundance ($2 million or so to complete the GVCS!), but hopefully my efforts to create and publish technical do-it-yourself how-to-build instructions will build an information bridge that will enable other teams to start building these machines and seeing places to improve the builds.

-

The following eight stages are grouped into five broad phases of hidden problem, increasing tensions, take-off, waging the movement, and success.

Stage 1: Normal Times

Stage 2: Efforts to Change the Problem Demonstrate the Failure of Official Remedies

Stage 3: Ripening Conditions

Stage 4: Take-Off

Stage 5: Movement Identity Crisis — A Sense of Failure and Powerlessness

Stage 6: Winning

-

gregor:

Mike: my thoughts exactly re the not wanting help. It is clear from several different angles that the inner circle of people just are not interested in contributions coming in over the internet. It's a foolish and wasteful attitude, they could get a dozen skilled people for every one at FeF if they played their cards right, helping with where they need it the most: design, planning, wiki and other office type work, etc. And to play their cards right they need only to listen to people who are telling them howWhatever, if they want to be that arrogant they can wallow in it. It will take years and years to complete the GVCS and when it is done it will suck because there will simply be very little knowledge and experience behind it.Guess exactly this will happen, Gregor! They won't finish the GVCS in 2013 and what they have "finished" will prob need much redesigning. What we see today in the wiki is poor mechanical engineering, and this is a gentle designation for some design details.

gregor:

Another good apparent example of lack of information that people need to do their jobs, is why Howard has to go all the way over to rural Missouri to get some dimensions coralled up. That makes no sense whatsoever. How can you make something as complex as these tools without having the dimensions written down already? Then just send the raw files to people to go through and produce documentation from. Don't tell me they are flying by the seat of their pants so much they don't even write down their designs

Its astonishing, OSE wants to develop designs for worldwide replication, but they don't even have the dimensions at hand to write technical documentation.

Even worse, if they don't write down the dimensions, they also won't know dimensional or geometrical tolerances or even the material grade they have used.

Sounds like a sophisticated mis-management. I wonder how much success might someone in Africa have in trying to replicate those machines :-o

Mike

-

No, Marcin is now bandying around 5 mil as the figure to complete the gvcs. See the blog comments. And I'm not faulting him for that specifically, >$100k per tool may indeed be what he needs to do it his way, because every time somebody shows up to provide free help he drives them off or drops the ball some other way.

The lack of man-power explanation can work for anything except something that multiplies the man-hours going into the project. For every one person that is both interested in OSE and can go to rural mississouri for a month, there are necessarily several people who are interested but cannot go. That resource is being wasted entirely right now. Heck that might be something like 90% of all people willing to put effort into OSE. Poor management.

Which I wouldn't mind so much if it were not for the lying about it. "If it isn't on the wiki it does not exist" is what he says the policy is, right in the blog post referenced by the OP. Not only is that completely not true, it is not even close, and he clearly does not intend to make it true, either (that blog post was a while ago). On the wiki you can also find a "scaling strategy" page where he tips his hand and makes it clear that people helping over the internet simply is not a part of his approach. And yet he runs around telling people that their help is wanted, and they should dive into the wiki and get started. When I said approximately as much in a comment on the blog, he promptly censored it.

My objection is not a matter of principle, either, he is seriously wasting people's time with his chronic dishonesty, which is extremely inconsiderate. How long did Howard spend documenting stuff that was obsolete? How long did Bastelmike spend getting up to speed and contributing based on information on the wiki, or only to find that he was being lied to on both counts about how the operation works? How many of your evenings, Allen, went down the drain because of Marcin's lies? And there have been many other people before. He's abusing people's trust.

(not to pile on, I actually wrote this before Mike left his comment, and I personally expect they will eventually document the stuff for the existing tools well enough. But that does not solve their main problems.)

-

I don't consider any time I've put into this to be a waste, because I went into it from the beginning, realizing that my goals weren't the same as OSE, nor would they likely ever be so. I've done research to further my own goals, and where OSE has been useful, or even thought-provoking, I've been thankful, and made use of it as a resource. Where it didn't apply, I happily discarded those parts.

I've put much more time into my own grand schemes, because I'm planning for my retirement, NOT for a new world order of society, mostly because I don't believe that being ill-prepared will feel very good 30 years from now, when the USA economy has long flushed down the sewers any value my social security or other retirement investments might have had. If I can plan for getting my retirement home to be a resilient home that meets my needs intrinsically, money won't have nearly as much value and/or the lack of such won't hurt (nearly as much).

I'm much more a follower of the ideas put forth by Mike Reynolds of Earthship fame, in that I believe that my home should be or become a facility that doesn't cost me a constant stream of cash to live in, doesn't require or involve public utility companies for water, power, or sewage, & can provide enough food to sustain me & my family/guests comfortably. To that end, there are some things that I don't exactly agree with in his designs, and am willing to spend more to get a little better,

By that same premise, there are concepts in many different groups that seem to be working toward very similar goals that would benefit from working together or at least borrowing from each other, and while there are some ideas in OSE I've not run across elsewhere, there is also some major duplication of effort for things in their "Grand Scheme" that have already been done by others - in some cases, quite well, and far past what OSE might consider a 'full product release' stage that they not only aren't using, but don't seem to adopt, even when someone points them in the direction of an open source project that has already 'been there, done that/moved on'.

Even if OSE doesn't or won't adopt other folks wheels they've invented, I'm not under similar restrictions, and can learn from anyone ;) I'm ok, and better off because of OSE, no matter how badly managed they are, were, or become, even though I'd like to see them get better with time.

-

DavidIam

What do you think will solve the main problems, Gregor?

I am not Gregor, but I will answer anyway.

A really professional approach to machinery designing and fabricating!!!!

You want to build machines, so start machinery building, with all it difficulties and special knowledge required; stop playing around with some square tubes connected somehow but odd and using everything like hydraulic motors just to get along complicated mechanical layout thus as a drive train or a gearbox. Believe me, if this simplifications would be such an ideal feature, commercial fabricators would have started using it many years ago already!

First, as far as budgets permit, try to build a well equipped machine shop. Without poles everywhere. Go and buy the most needed machine tools used, but have an experienced machinist with you when buying. I have already written above which tools are probably the most needed for a start.

Second, use the skills of people willing to help in an optimal manner. Let everyone do the task he is capable of, and not everyone everything.

- For complicated machinery desing you need engineers or technicians with appropriate education and experience.

- For the difficult tasks in a shop you need skilled mechanics and machinists. Don't let everybody do jobs that they have no experience with. Welding is something people should have a lot of experience before having them weld connections with high tensions or that must be watertight

- People with a study of physics or chemistry are qualified for doing basic design jobs for complicated processes like aluminium extraction, battery layout..

But they should not try to design the layouts of finished designs, as they don't have the skills in mechanical or electric engineering and are usually not qualified to calculate design details

If You have some volunteers without those special qualifications, its okay and OSE will benefit from that. But, you always need a balanced mixture of the qualifications I mentioned above. You can't replace one engineer with 10 willing volunteers without that qualification! You always will need a mixture of those qualifications at FeF !

Still another point I noticed while reading many wiki pages. Most people that do these one-month-visit at FeF, are very young, below 30. Well, they may be powerful and enthusiastic young people, but without experience in any profession. One retired engineer of age 65 may be more beneficial to FeF and OSE than 10 unqualified young volunteers.

Last point, try to use online help and advice as far as possible, especially if at that moment no one with real qualification is present at FeF. Why is it a problem to pose a planned design on the web and ask people to do a review of certain design details? I am sure there are a couple of people active in the wiki and the forums who are engineers or similarly qualified in some subjects. Use this knowledge base.

Thats all advice I can give You, David

Mike -

> We also don't know how to collaborate with remote people effectively.

We haven't learned how, we haven't even had the time to try and figure

it out.

I should note that there have been offers from people who are quite experienced in coordinating these kinds of activities to help guide OSE in setting up, organizing, and managing remote, distributed projects. To my knowledge, most of those offers were rejected. The problems go deeper than a simple last of knowledge, David.

- Mark

-

> What do you think will solve the main problems, Gregor?

MikeBastel's points are all good ones. I would add another: delegate management to competent people and then support them in that function. It make a lot of sense to separate out some of the major GVCS projects and delegate them to project managers. This has been done in some cases - myself and YK come to mind. However, once the initial design work is done, there is NO support for moving to the next stages of development - like prototyping. Marcin should be a high level leader and visionary. He doesn't need to micro-manage every aspect of OSE development.

- Mark

-

First, when professionals are given the budget we have to design and fabricate equipment, they give up. They consider it too hard, too tedious, and 'wrong' given their experience. they can't do it without this tool or that software. Make do. you can find a way if you try. But they generally won't.Consider the design goal of power cube modularity. When something goes wrong with your power cube, you should be able to replace it in a minute or two. If you need more power, you should be able to put a more powerful on on easily. if you need more efficiency, a less powerful one. If you are going to criticize the design that directly meets this goal, you're going to have to disqualify the goal first. Since its pretty obvious to me why modularity is not a good way to make lots of money manufacturing goods for commercial sale, I present you the question: Why is this modularity a bad goal for an open source system of power equipment?How well equipped the machine shop is has little to do with the frequency of columns supporting the roof. Please explain how working in a space that has columns is any different than working in a space that has machines in it? They both restrict where you can walk and what you can move around. It doesn't matter if your bench or lathe has a column behind it - you won't be walking there anyway. Open factory floors have obstructions hard-mounted to the floor all over the place. I fail to understand why the columns needed by our simple roof and masonry construction cause such a negative reaction in you.Its not as if I didn't have the design in an illustrated form up on the wiki for the last two months. Nobody has contacted me to discuss its design at all. Not Even You. Do I have to post to the forum to get a reaction? Do I have to have marcin make blog posts? What does it take? Obviously, I don't know how to spur this reaction in people where somebody who knows why the building really shouldn't have columns in it is going to talk to me about it *before* the parts for the current design are bought and assembled.NEED engineers and technicians? What definition of 'need' is this? the CEB press was built and works awesomely without an engineer or technician with appropriate education and experience. Further, what is the alternative - that Marcin and company sit on their arses recruiting like mad online to get experienced engineers and technicians to come onsite? Or would their time better be spent designing and fabricating something?The FeF doesn't have the choicest people onsite. Skilled technicians are likely invested in a job, a house, and a car, debt, and a million reasons they can't run off to the farm. Admittedly, we should compromise on this by teaching people much more rapidly. We should give them experience so that they can do a good job. But we have difficult tasks. It is better that they be done clumbsily, with errors and repairs, than they don't get done at all. Its easier to fix the mess made while gaining experience than it is to get the people with experience onsite.I agree that we need more mixture of skills. But we don't have them. FeF has been bit over and over with people being lazy, people being flakes, people not being capable of what they said they were. How many times do you get burned before you throw your hands in the air and walk into the shop and at least make some progress. The one thing that is not considered an option - not even close to maybe - is sitting on our duffs looking around at each other instead of at least trying. Doing and Trying is what we CAN do.Because posing a planned design on the web and ask 'people' is not an established procedure. Lets say I do manage to find the appropriate forum for posting a planned design on the web. Hell, lets try it with the Hab Lab. I'll create a new thread on the forum here. We'll see what happens. How long will it be before we get a response from a qualified person?Yeah, its emotional, and its less than optimal, and I wish you could come and manage the everliving heck out of us by spending 60 hours of your time every week enabling us to do what we do best by you doing what you do best - at least - if you have other talents then telling us that we're doing it wrong. ;)MJN - I'm not part of the selection of people for management. The problem in that case is not deeper than a simple lack of knowledge - its merely lack in a different angle - as in, lack of how to understand how to allow somebody to organize a remote and distributed project. Its easy to reject things you don't understand, and I have well seen how Marcin has a tendency to do that - I have to explain my building technologies to him before he can accept them. It has to be something like what I pulled with the construction management.Well, it needs done, I'm going to try and do it. I have some time and I'll do what I can to show it and make it happen. Better to try and get rejected than to stand around waiting for permission from Marcin. Maybe its weasely. maybe its risky in losing my time. But its my time to lose, and if I'm going to help with OSE, I've got to spend time on it. Perhaps the evolutionary talent we're looking for is the person who can convince Marcin that he is trustworthy, will dedicate the time to it, and will smoothly manage the project. Even if the 'support' isn't as strong as would be ideal.I say this with affection, but Marcin is a geek with a dream. He loves working with metal and making things. He is visionary, but is he a high level leader? It may be too much to expect from him personally, especially without an able personal assistant. Can we still, together, collaborate and make OSE a success by wedging in some high level leadership to enable his vision?

-

I think the main problem of not having a good shop will be solved by the shop I am managing the construction of.I think the main problem of not having sufficient tooling will be solved by having a shop to put good tools in, and some capital to buy tools with.I think the main problem of not having proper collaboration will be solved by a volunteer manager providing the management of projects and tasks and wannabe contributors regarding the realistic assessment of the abilities they have and the time they can commit to the project. This needs a special person.I think the main problem of not having experienced technicians onsite will be solved by having a place for them to live and a formalization contract of basic room and board and a small stipend provided from OSE resources. This will FURTHER require a household manager volunteer, onsite, to manage the cooking, cleaning, and general household issues. (As much as Howard is being seen as a documentarian, I am sincerely hoping he can fulfill much of this role) (I also suggesting my aunty for this role, but she had to go to Georgia (the russian state) on a prior commitment for the time being.)I think all these problems can be solved, and insofar as I can enable them to happen, I am. My friends, my family, my resources are thrown at this, in my perception, valuable project. Marcin is less than optimal. Hell, i'm inefficient myself. But I think we can figure it out. You and Me and Marcin and everybody.

-

At the very least can't someone volunteer or even hire a virtual assistant for Marcin? I can get a Filipino engneer for a couple hundred a month. I can't kick in the whole thing right now as I'm building my own shop to replicate the open source machines from here, and several other sources, but I can come up with some cash....

-

DavidIAm wrote:

Why is this modularity a bad goal for an open source system of power equipment?Why is this modularity a bad goal for an open source system of power equipment?That are two long posts from, I'll try to answer some points in different posts.

Modularity isn't bad, in fact its a good idea, but with disadvantages and limitations. Cost for manufacturing these designs might be a bit higher, with prospects for future savings. Efficiency is often lower.

But the real problem is, modularity isn't really scalable. A larger more powerful power cube isn't easily compatible with the current one; its dimensions will differ, hoses and couplers will have different (larger) sizes.

And it won't be an easy quick attach! You cannot carry a 200hp power cube. You will need a crane to lift, transport and reinstall it. David, do You think a farmer is willing and able to move his 200hp-power-cube several times a week, from combine to tractor to truck?

So what is the benefit from modularity for him?Mike

-

DavidIAm wrote:How well equipped the machine shop is has little to do with the frequency of columns supporting the roof. Please explain how working in a space that has columns is any different than working in a space that has machines in it? They both restrict where you can walk and what you can move around. It doesn't matter if your bench or lathe has a column behind it - you won't be walking there anyway. Open factory floors have obstructions hard-mounted to the floor all over the place. I fail to understand why the columns needed by our simple roof and masonry construction cause such a negative reaction in you.Many columns in the interior of a building consume floor space, and more important reduce the utilization of the floor space significantly. This effect ever increases when workpiece and machinery dimensons become larger. Columns are a severe handicap for manufacturing and internal transport!1. aspect: material handling and material flow

In metalworking you will have to deal with many parts and assemblies that are much too heavy to carry them around. Therefore you need a lifting capability for most machine tools (except the very small ones) and for areas for assembling large parts. There are two methods used for this, overhead cranes and forkifts.

If you don't have columns in the shop you can install one overhead crane. In the FeF shop you would need 3 cranes. 3 cranes will be more expensive than 1 (longer) crane, but more important, if you have no columns inside and one crane, it could transport parts everywhere in the building. With three cranes, you would have to lift a part, put it one a trailer and roll it in another row of colums, where you attach it to the crane again.

I would regard this already as a severe handicap of your design2. Utilization of floor space

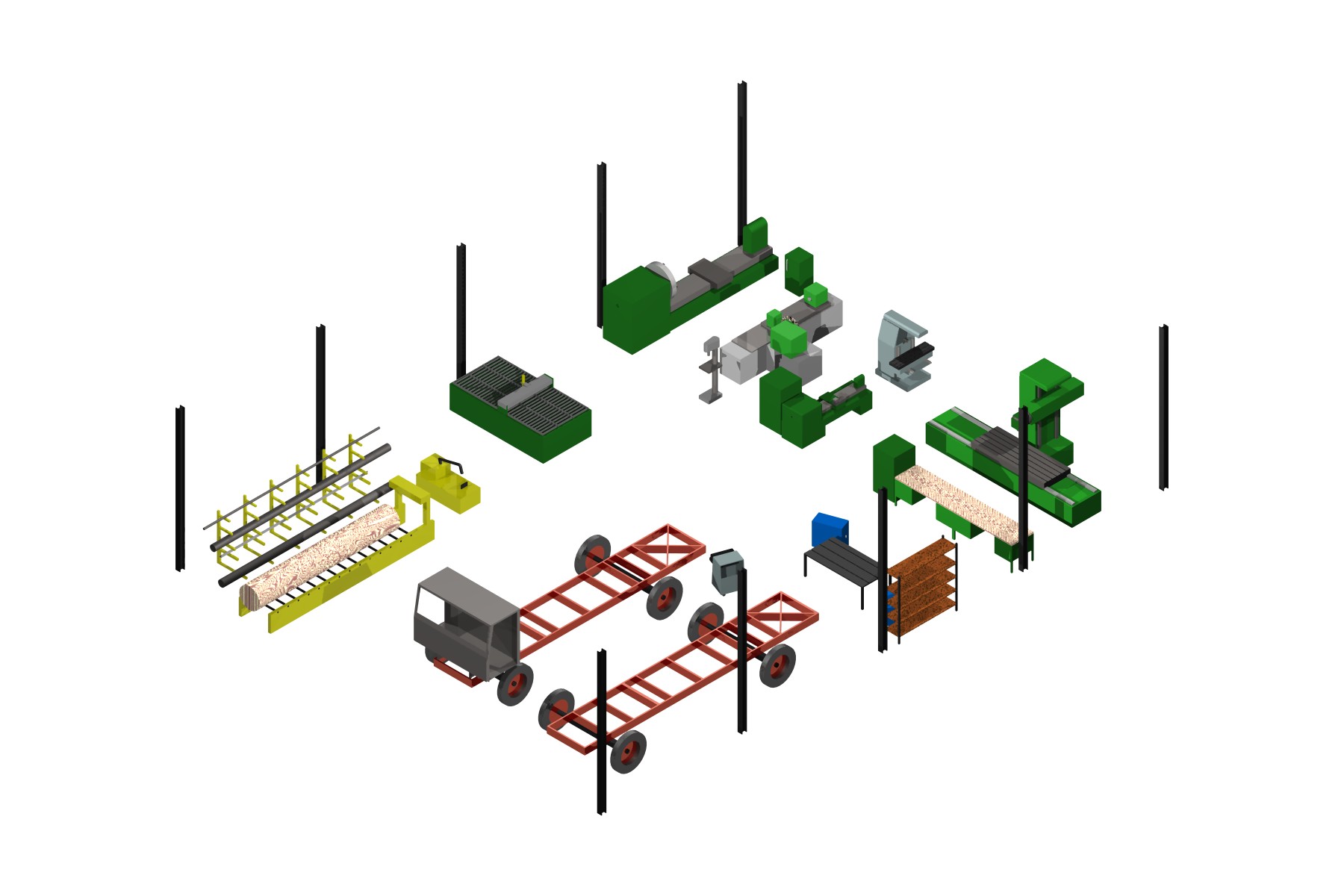

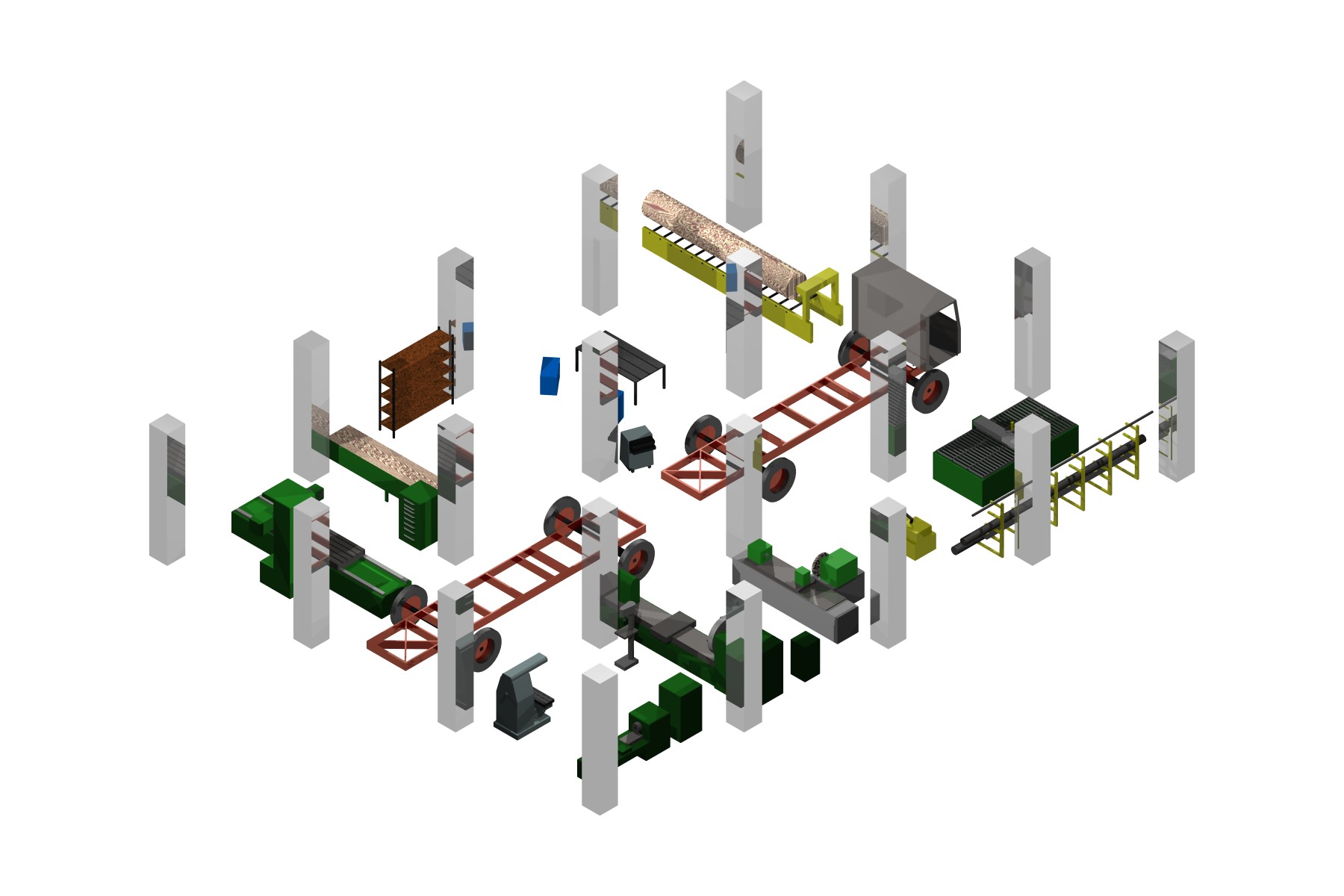

To explain what I am talking about I did 2 small CAD drawings showing your shop with equipment; with those brick columns and with steel columns only in the exterior walls 48' apart.I hope you will see what a difference it makes...Attachments

OSEVergleich2-1.jpg 155K -

If they've already scheduled a concrete pour, and also have placed & bent the rebar, set forms, etc., any further discussion about this particular shop layout is probably a moot point now, as it is literally about to be set into concrete.

Perhaps lessons learned from this shop, both good & bad, may be used for the next iteration.

It isn't too fair to blame BastelMike for not commenting earlier, because he hasn't been around all that long, anyway, and the material for OSE is so spread out between the forum, the wiki, the blog, etc., that one couldn't have had a chance to go through all of it yet in only 6-7 weeks, especially if they had a life, a job, a family, etc. (BTW BastelMike is showing as having been here only since Aug 4th)

I do remember seeing the proposed plans for the shop layout, but since I never really got the idea that my opinion would amount to a hill of beans and it wasn't my shop, I declined to say anything about it, on the assumption that whomever was going to build that had their reasons, and I just let it go. It is also outside of my area of expertise, so I had to assume that they had input from *someone* (else), and that was that.

Part of the problem is that if the outside volunteers are all too often ignored, & feel like their input is wasted, they won't often bother to offer their inputs.

-

A lot has been done and happening at FeF. I think its misleading and unfair to declare an idea has been rejected or someone is being willfully ignored. Time is thin and stuff needs to be done such as going for grant funding and keeping production rolling with a small crew of volunteers who have to provide for their own necessities while not earning a wage. Keeping up with the forums and stuff put on the wiki would gobble hours each day that, it is my understanding, they do not have the time to spare.I believe they could use someone who can organize the stuff, but until someone steps forward and does it, its time better spent prototyping machines and fabricating existing ones to sell to help fund the movement forward. From Marcin's recently posted video, the construction expansion is eating the last of the money reserves. There's a lot of stuff to get done with few resources to do it, and the pressure and workload I imagine are high.

-

I stand corrected. When, from the outside, it "seems" as if volunteers are being ignored (regardless of whether or not it is intended or not), volunteers will all too often, feel like their input is wasted, and not bother to continue to offer input. :)

And this isn't to affix blame, only to clarify the circumstances, because, regardless of why, it still has the same effect.

Howard, check your PMs too. :)

-

Sorry for the delay, I had some trouble with the uploads

Here are the other views to compare

Attachments

Vergleich_komplett.zip 687K

OSEVergleich1-1.jpg 162K -

You're going to have to annotate a bit. Bastelmike. I see that you created different layouts for with and without columns. They look roughly equivalent - workflow happens in a different way in the different places - from a japanese efficiency point of view, its less optimal, but its not so optimal that production comes to a halt or people spend their days running back and forth. Production will be done in either shop. It may have a wider profit margin in the no-pole shop. thats not much of a considering given our non-profit status.You didn't show how we design and build simple and easily constructed roof trusses to span a 48 foot or so span, which is the biggest stick when it comes to making a long span roof, and the biggest reason we have pillars in the middle of our building.

-

@DavidIAm

Yes, the layout is different, just to show that you have much more flexibility in a shop without interior colomns. But those two shops have exactly the same equipment in them and their dimensions are equal.

Please tell me, David, how you want to install larger machine tools as I have used in those drawings in Your shop if the need arises?

And how Do You plan to move heavy parts in your shop? You don't have enough space to operate a larger forklift in it, and building 3 overhead cranes is expensive.I already posted earlier how to construct a shop, with "open source plans". There are a lot of DIY plans available in the web for agricultural buildings. The specifications for a large farm machinery storage and a shop don't differ that much. Just google for "Canada plan service" or "midwest plan service". You will find detailed designs for buildings, designs that have been static calculated. I am not sure that has thoroughly been done for your shop. If You don't find what You need, just PM me, I will send You appropriate plans.

A dimensional sawmill is part of the GVCS, so why not use woodfor such a building. Wood or steel are bettr suited to that type of buildings and nearly noone builds them today with masonry. Maybe You could ask Brianna about the differences of wood/steel and brick poles to withstand horizontal forces like windYou have criticized me for not having commented earlier on the design. But I am only involved with GVCS since 6 weeks, and regarding the way information about OSE is organized, or better widespread, its for noone possible to review all documents in that time. But after reviewing that shop design, I had to do several comments. I believe after a study on mechanical engineering - manufacturing technology, I can make some qualified comments on a shop layout. Sorry David, but a design doesn't work better if no one dares to criticize it.

Mike

-

Larger machine tools... the lathe we have here fits between columns. The metalworkers I've seen for sale fit between the columns. the operational envelope of the Fanuc robots we have a chance to acquire fit between the columns (barely).You didn't note in your design that our shop has 21' centers along the east and north sides - there is an extra 5 feet (17 instead of 12) between the columns, so there's a little more room than you visualized there. Naturally, larger machine tools would gravitate towards the larger compartments.If we have a really big machine tool that simply won't fit in our shop without the removal of a column or two, well, we can work with that. Build a truss, build an arch, whatever we need to to get the job done. Adapt.I plan on moving heavy parts on casters, on my smooth concrete floor that I have advocated for. We really did think about making a crane, but we don't have steel pillars, masonry pillars are *not* a safe thing to put a bridge crane's rails on. Further, to have people moving things around with a crane is actually quite dangerous - keeping objects close to the floor seems a much saner, safer, method of moving them around. So how to move heavy things? Jacks and casters. And this is from some consultation with designers of factories.Canada and the midwest are steel central, wood truss central, its exceedingly easy to find fabricators and suppliers for that stuff here. But they have jigs and capital and industry on their side, it is what they do. In order for GCVS to be replicable without that kind of infrastructure already available, we're going to have to publish how to do what those suppliers do, yourself. And that is not simple. Ordering an engineered truss - easy - building an engineered truss - problem.I appreciate your critique. I hope you can understand that many of these things we have already considered - because we decided differently doesn't mean that we didn't think of it. I placed a number of different tools into my model to see how they fit - tables and saws and welders and metalworkers and even a mill. I put an F350 in it (since I have one) to see how that felt. A CNC system. A cutting table, etc. I agree that its less optimal to have columns, but, I don't have an open source handbook on how to calculate the strength of a truss designed out of my own lumber and materials.Consider that the primary reasons not to build things out of masonry is convenience, labor and materials - masonry is a material heavy, labor heavy construction method. We have the material - earth - we have the labor - well, we wish we had the labor, but we can make do. We're not trying to buy our way out of the problem so we can get past the building and get to the making - we could put up a quansett trivially after all with engineered materials. the building is both utilitarian AND an experiment.Do you have any suggestions on ways to move the building from being center-columful to center-collumn-less? How would you retrofit it? would you replace the whole roof? replace the current minimal truss setup (engineered beams) with a deep tension-membered truss setup? Do tellDavid

-

David, the most recent posts in this thread and the other thread on the design review of the shop could hardly be a better illustration of what I have been trying to tell you. Pretending for a second the shop was still even in the design stage, Mike and Allen and Howard are forced to make wild guesses about what is going on over there, from how you plan to do the insulation to what the shop, what work has already been done, where progress is, the list goes on.

Where is the analysis that your uncle did? The test results from your other family members you mentioned? The reviews of the design from those experts?

This advice is next to useless to you, and it is certainly a poor use of the other people's time, because no one can build on your existing work without having access to it.

If you still don't believe me I suggest you email someone who lists relevant skills on their team culturing survey, and without spending time providing any additional information than what is already on the wiki, see how usefull(less) their advice is to you. No matter how leet their skills are or how fanatical about the cause they are it will still be relatively useless because you didn't do your part in the consulting relationship.

Solution: Next time you are designing something, put all the information up on the wiki that people need to be fully in the loop, in one designated place and with some semblance of organization, and then email some people who have the relevant skills (make sure they are in touch with each other too) using the team culturing survey.

Only a fraction of the people interested in ose are interested in the type of higher level discussions that tend to happen in the forums, and I would expect just as few or less to scan the wiki looking for places to jump in.

If you don't have time to do this (consider it a low priority) then you don't have time to bring effective help, so you will end up having to do without.

-

That is fair enough, Gregor.The analysis my uncle did is inaccessible even to me at this point, it was never written up in a form that was communicable beyond face-to-face conversation. The test has not been run because the CEBs have not been produced to provide the weight, because the power cubes are not running because of lack of manpower onsite on their construction.You are suggesting I invest time going through team culturing surveys to find somebody with relevant skills, with no guarantee that (presuming I find such) when I contact them they'll have the time of day for me or the project. It feels (emotional I know) like a high risk use of my time.Which brings up the fact that the team culturing survey seems to offend people by asking too much... I'm not sure how many people haven't completed them because of this, but I've had to talk down at least three people from bailing simply from reading the question list. Off topic to this subject but, an issue when it comes to getting effective help. It worries me.I'm not sure how much time I need to spend on organization, management is a very new thing to me and it probably shows. I'm also worried that posting on the forum alone won't get replies... the design for the hab lab, for instance, above the excavation level (which is supposed to happen today) is still being finalized and anybody CAN contribute to that. The model is uploaded per the forum post.

-

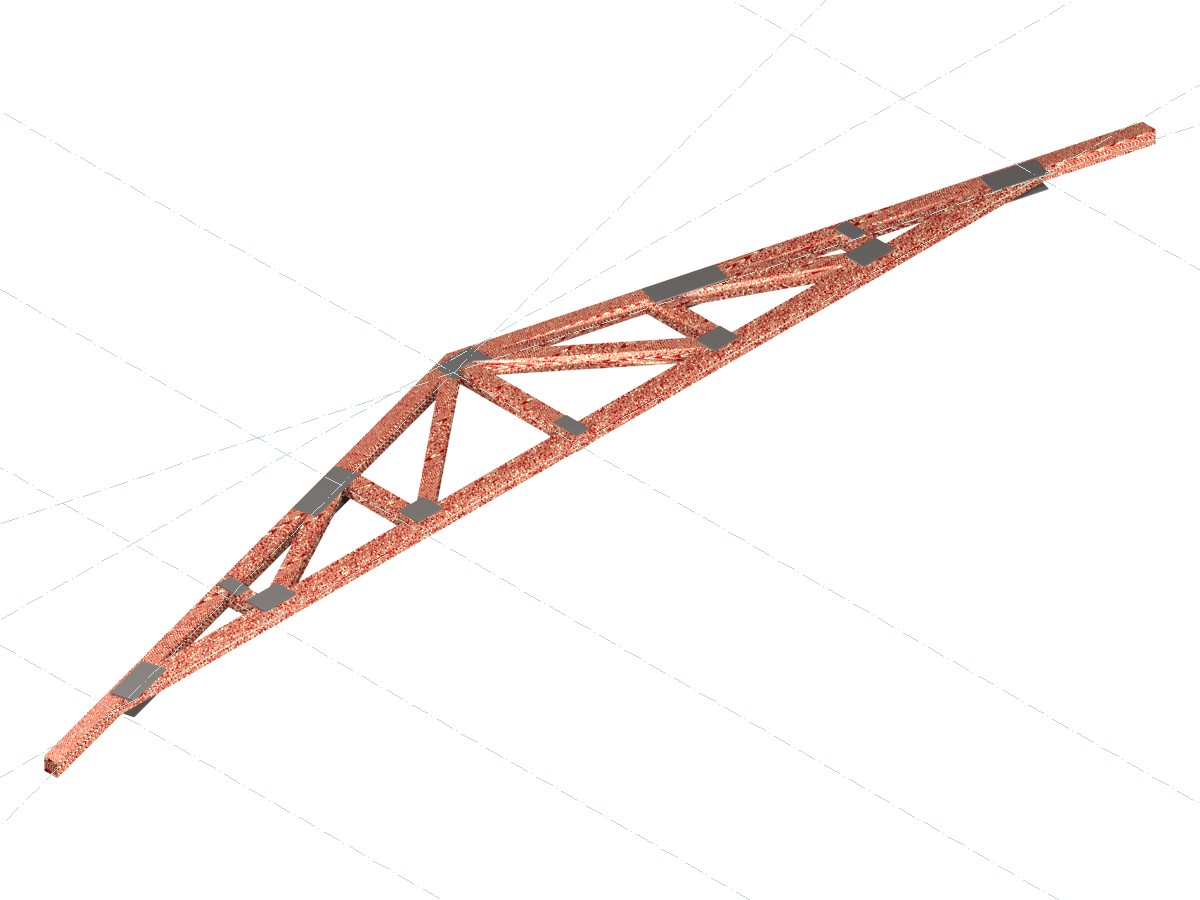

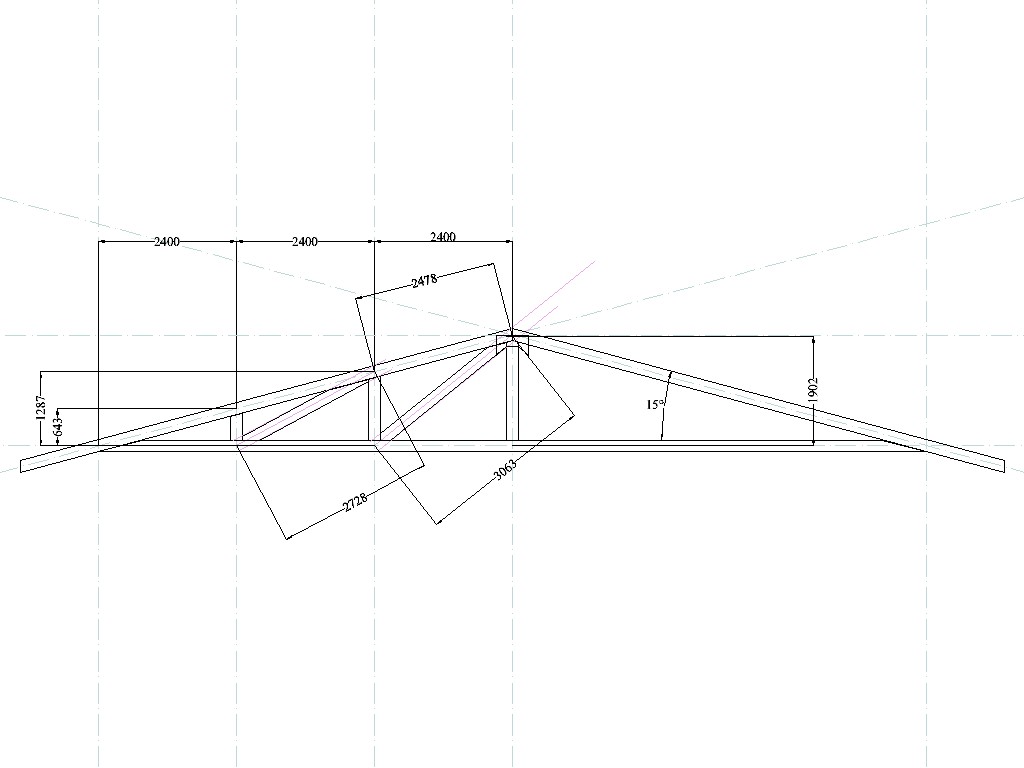

DavidIAm:Do you have any suggestions on ways to move the building from being center-columful to center-collumn-less? How would you retrofit it? would you replace the whole roof? replace the current minimal truss setup (engineered beams) with a deep tension-membered truss setup? Do tellWell, David,

first point, I'm not too sure if it makes much sense to change an already built shop from intermediate columns to column-free. You ae located at a farm so You should have enough space for buildings. Work hours and capital for materials would prob be more useful in building a second shop or a shop extension than in rebuilding the roof it is finished. And You will need additional shop space for some of the larger machines in the GVCS set, including the need for several really large machine tools like lathes and mills.Second point, if those midwest plans aren't enough for You to build a truss, what do You need? A plan and a static analysis for a truss like the one on the pics attached?

But for proposals for a roof replacement, I would have to know how Your current roof looks like, including dimensions.Third point, sorrry, I am not native english speaking,, what is a deep-tension-membered truss? Maybe You can show me one David?MikeAttachments

Dachbinder-1.jpg 100K

Dachbinder-2.jpg 63K -

DavidIAm: I plan on moving heavy parts on casters, on my smooth concrete floor that I have advocated for. We really did think about making a crane, but we don't have steel pillars, masonry pillars are *not* a safe thing to put a bridge crane's rails on. Further, to have people moving things around with a crane is actually quite dangerous - keeping objects close to the floor seems a much saner, safer, method of moving them around. So how to move heavy things? Jacks and casters. And this is from some consultation with designers of factories.

Uhh, no crane!!!! Think again please, David!

For the GVCS set You have to manufacture real heavy parts. Bulldozer, steel roller, forge press.....

I have a selfbuilt crane in my homeshop. Usually my parts are not so heavy, but just lifting the lathe's large faceplate, the vertical milling head attachment or the round table needs one! If You can't build an overhead crane, use a forklift or a movable portal crane. Yes, those columns are a drawback then, but thats prob Your own design, David.

I don't believe You will ever get a steel rollers roll between the centers of such a heavy lathe without crane !Mike

-

The main objection to the midwest manual is that its not as relevant outside the midwest. If you were in, say, subsaharan africa and somebody handed you a plan that requires metal gussets, they may as well be telling you to just order a steel building frame from a manufacturer in china - its every bit as far out of reach. As an organization that is trying to prototype designs that are usable *anywhere*, to choose a design that only works with the specialty supply chain of the midwest approaches an absurd choice. Do not assume that gussets are going to be available, and these kinds of trusses cease to be viable.Further, these designs require many fairly precise angled cuts - not to say you can't do it - but every single cut is another possibility for a mistake and waste. We want it to be modular and simple - the idea being if I want a roof that spans 10,000 square feet instead of 5000 square feet, I merely extend the existing simple pattern that I learned - rather than having to go to a book and find a different design with more specialty fastener requirements, and different lengths of wood, different angles to cut.The big benefit of these engineered roof trusses is that they're made in factories - by people who have the jigs, plans, and setups to do it right and quickly. They're fast and strong when you have gussets and experienced builders. We are not experienced truss builders, and we don't think you should need Gussets to build your roof.I was visualizing a parellel chord truss when I said ' a deep tention-membered truss'

-

The fact remains bastelmike that *we cannot safely mount a crane on our ceb columns*. Its simply not safe.If we need a hoist in a spot, we can utilize a wheeled gantry crane. It can have a bridge member long enough to straddle equipment like a lathe, hoist as necessary, then be moved out of the way.Even if our columns could support a crane, bridge cranes are also expensive - we're talking, 10,000 for a 70 foot bridge crane and that's pretty much just the raw steel materials, not even something that is really built up and engineered with power and actuators and such.So what is the way to get past the capital demand that is so high - as much as the rest of the building, just for the crane? Its a valuable tool, no doubt, but its also very expensive just in raw materials. Can we get along *without* a crane? Can a wheeled gantry do the job that we need it to instead of a large building-sized crane? We have a good smooth concrete floor. That enables a lot of rolling around and continuous support. Large heavy things can be moved.So I posit the question - is that good enough?

-

@DavidIAm:

Is that good enough? Its good enough for beginning! A wheeled gantry will help a lot, its what I have proposed with a "mobile portal crane". Look at this page for some details:

http://www.rosinski-hebezeuge.de/Wimag/Portalkran.php

I guess the type V204 would be the size You should built. As You can see You will need a lot of free space in the shop to manoever it around. How about the internal height of your shop? From top to bottom of I-beam You need 12-14" and additional 18-22" from there to the hook. Thats about 30+" inches you loose in height.

with a two ton crane like this you can manufacture most of the GVCS set, except the real large and heavy machines, but for those the OSE shop is too small anyway.

You are right at that capital demand is high. With less than 100,000$ for machine tools, cutting tools and measurement equipment You won't have the shop to build the GVCSset. Thats fact, David.

If You try to build the machines without proper equipment we will end up with all designs in lifetrac quality,a really frustrating outlook.

Mike

-

That makes it sound like you'd throw your hands up and say without the funding there isn't any point in even trying. (with that attitude, we wouldn't have gotten where we are)Its open source - I doubt these designs will survive unaltered by *us* much less other people who are going to produce them in the future. At least they have somewhere to start, there is *a* design, even if its not the best in the world. A tractor that you can both create AND gets some work done is better than pushing it all manually yourself, even if its not the best design out there. Cost and producability are *very large* components of a GCVS design - not perfection for a particular purpose. The lifetrac is kind of like humans that way - we're not particularly good at anything in particular - but we can adapt ourselves adequately to just about everything.Until you have the power (in resources/capital) to make a specific optimum machine for each purpose, its better to have an adequate machine than a perfect one, don't you think?We do have something like that already, actually - we'll have to mount wheels on it if we want to roll it around - but we do have a hoist on a crossbeam almost exactly like that. So at least we can lift heavy things a bit. Thats something.

-

@DavidIAm:

Is that good enough? Its good enough for beginning! A wheeled gantry will help a lot, its what I have proposed with a "mobile portal crane". Look at this page for some details:

http://www.rosinski-hebezeuge.de/Wimag/Portalkran.php

I guess the type V204 would be the size You should built. As You can see You will need a lot of free space in the shop to manoever it around. How about the internal height of your shop? From top to bottom of I-beam You need 12-14" and additional 18-22" from there to the hook. Thats about 30+" inches you loose in height.

with a two ton crane like this you can manufacture most of the GVCS set, except the real large and heavy machines, but for those the OSE shop is too small anyway.

You are right at that capital demand is high. With less than 100,000$ for machine tools, cutting tools and measurement equipment You won't have the shop to build the GVCSset. Thats fact, David.

If You try to build the machines without proper equipment we will end up with all designs in lifetrac quality,a really frustrating outlook.

Mike

-

One of my design modifications on the shop was to raise the roof significantly - its 9 feet (108 inches) high in all but the last 10 feet on the east side. That puts the lift height at about 78 inches with a perfectly sized wheeled gantry, which is tall enough to be useful.GCVS items we can't make in our shop... looking down the list...its obvious we can't fit all of these in the shop at the same timeBut if you were specifically making any one of the devices, not even the windmill would have trouble being fabricated in the shop - there's enough room to lay out molds for 25' airfoils.The truck would be crowded to assemble in the shop, but you make do with what you have.The well driller machine wouldn't be able to be unfolded in the shop, but you could put it together in there.Which ones do you think wouldn't be able to be assembled in the space of the shop? I agree we'll need cutting measuring and milling equipment, better tools. But I don't see how the shop itself is inadequate, only its current tooling.

-

Well David,

I have a lot f doubts if You can manufacture an extruder and an bulldozer(with real power and weight) in that shop.

But two other designs come into my mind that need much larger machine capacity and crane capacity than available in that shop.

#1 is the steel roller. Those rolls have an diameter, lets say between 12" and 20". Usually 2-5 yards long. You will need a lathe with a corresponding swing, and that is swing over carriage! Hopefully You know what size a lathe is with a swing over carriage of 20" is - a very large and heavy machine. Manufacturing the frames for that design will also call for large mills or boring mills. A travel of 10' might be sufficient - no parts for a knee mill, David

#2 is the forge press. Very small ones start with a force of 500 tons, the real large ones are 8000tons or a bit more. I didn't found data about their weight on the hurry, but I guess, estimating the weight as 10 percent of press forge could be a good first guess. In Your shop without a heavy mounted crane You will never be able to move the parts and not be able to machine the parts either. If You don't think so, just tell me how you assemble a 100 ton (mass) press with a 2 ton wheeled gantry crane ??

So these machines are the hopeless ones in the GVCS set that come to my mind momentarily...

Mike -

DavidIAm wrote

That makes it sound like you'd throw your hands up and say without the funding there isn't any point in even trying. (with that attitude, we wouldn't have gotten where we are) Its open source - I doubt these designs will survive unaltered by *us* much less other people who are going to produce them in the future. At least they have somewhere to start, there is *a* design, even if its not the best in the world. A tractor that you can both create AND gets some work done is better than pushing it all manually yourself, even if its not the best design out there. Cost and producability are *very large* components of a GCVS design - not perfection for a particular purpose.

The lifetrac is kind of like humans that way - we're not particularly good at anything in particular - but we can adapt ourselves adequately to just about everything.If You don't have the basic equipment to build machines you will fail. Leonardo da Vinci designed excellent machines for his time being, but none of them was built because the technology, the tools to produce them didn't exist.

If OSE/FeF cant acquire good and sufficiently large (used) machine tools like lathes, mills, grinders, gear machines it won't be a success story.

Yes, I see and acknowledge that You already have done some projects. But,if You are honest, it were the easy ones? Those who required neither complicated designs nor high precision. All those components were bought off the shelf (engines, motors, pumps, couplers).

And the one that needed a complicated design, the tractor, is a complete failure! Nearly everything a farm tractor should have and be able to do is missing from lifetrac3. The Lifetrac2 broke in two when playing with a backhoe, without really doing excavation work.

Because FeF wasn't able to make a working articulated link, they "forgot" to build any steering in Lifetrac3 :-))Look at the videos Lifetrac3 making a 90° turn on the the road - with some reversing... It's no design to improve but to forget about at once

Mike

-

A shipley lathe of that sizeLength: about 21 feet. The shop is over 70 feet long and 50 wide. This is large equipment, but the shop is noticably larger.Lift height required to get a 20" roller onto the lathe? Center has to get about 5 feet high. Can I do it with a nine foot high wheeled gantry crane? Yes.Forge... well, yes, you have a point. You probably couldn't build that in this shop. I suspect it would get its very own press-forge-building shop. I hadn't realized the scale those things exist at. Certainly not a reason to think that the shop we have is inadequate to our purposes in regards to the rest of the set though.We have no disagreement about the need for machine tools, or the quality of design that comes from being able to work with machine tools. You can stop trying to convince me we need good tools. I know this.Your dismissal of the design is dismissive of the effort in design and construction that went into it, which seems overly simplistic and nonconstructive. It sounds as if you're saying nothing was learned, no element of the design is redeeming in any way whatsoever, that all the work was wasted and we should start over.Skid steers are a standard, common type of equipment that do NOT have articulated steering mechanisms. Mirroring that simple design is a logical path you seem to be ignoring. Your apparent amusement at the lack of steering articulation is not shared.Hell, in my opinion, if the hydraulics aren't doing the right thing to make it steer as desired *we need to rebuild the hydraulic circuits*. The effective application of power is as important to operation as the frame - its merely a component of design - and one that can be reconfigured without touching the frame.I also happen to think the frame for the lifetrac should look like a bobcat - sheet steel - provides weight and dimensional sturdiness, but that'll be a future prototype, perhaps.

-

@DavidIAm

Yes, You can push this lathe in Your shop. Turning it around 90° will be difficult or impossible. About the crane, we both did agree days ago that maximum height of the hook will be around 78", so lifting parts for that lathe might become difficult. But lets say it will work somehow.

Talking about the tractor, You may call me nonconstructive, though I don't think I deserve it. I am not the only person complaining about the current design, I have quoted other posts in this forum already before.

The task was to build an agricultural tractor.

Skid steering isn't common for these tractors, I know of no brand selling them. They are built for construction purposes where damage to the surface and soil doesn't matter. And please look on those skidsteer designs: they all have a very short wheelbase, the tires nearly touching each other which is a condition for that steering to work.

As agricultural tractor it's already unusable just because You won't get a permission to operate Lifetracs on roads, but most farmers need to do this. Most farmers don't have all fields adjacent to their farmsteads; in countries where farmers usually live in villages they never have.

Therefore I consider the tractor to be a case for a complete redesign from the beginning.

You can blame me for that, David, but I am backed by the OSE specifications like #8-High Performance, #9-Industrial Efficiency, #13Lifetime Design. In contrary, I havent found any specification there, that GVCS tools can be build without tools, skills and bought quality materials and components!

Maybe there needs a very basic discussion to be done about OSE yet, because it has not been clearly decided before: Is the GVCS set done with focus on

A) industrialized countries with focus on performance, accepting need for some capital to buy materials and components and the need to have adequate production facilities and skills

or is it

B) done for third and fourth world countries, sacrificing performance and efficiency, but enabling people there to build the GVCS set without capital for materials, taking them instead from the scrap and also having nothing than some stone age tools to build the machines.

My impression, You cant serve both goals with one set, is getting stronger and stronger with every discussion I read here and maybe take part of it. So, David, is FeF working for option A or B ???

Mike

-

@Bastelmike

> You cant serve both goals with one set

I think you are painting this too black and white. While OSE hasn't really looked at what it will take to develop GVCS tools in areas that lack access to capital, existing parts, etc., it has examined the notion of bootstrapping. The GVCS does contain tools that make make better tools. There is the notion of evolving the design in stages: machines using of-the-shelf parts, making the parts, and full fabrication from raw materials.

The LifeTrac is clearly an example of an evolving design. So what if LT2 broke? It's been improved and it will continue to improve. We could drop the tracks, for example, which would lessen the impact on the land. Rack and Pinion steering would be very to add to eliminate skid steering. Yeah, it may take a long time before it is street legal in Catalonia (or where ever). If that's a local requirement - work towards it. Saying that it is useless and should be scraped as a design doesn't really gain us anything. What would you do to improve the existing design?

- Mark

-

Spinning the lathe in place isn't even a consideration. Moving it around a corner, there is room for that, not even difficult. Put the ends on piano dollies (well, really strong ones) and you can move it anywhere in the shop you like. If I was going to build a lathe myself, I am particularly interested in the concrete designs - in which case, I don't think I'd be moving it, at all, ever.Tractor designs are welcome as are designs for everything else, in my observation. I have a number of ideas myself, but I'm critically short on personal manpower between the hab lab and shop design and construction, I necessarily delegate the tractor construction and design to others who are focusing on it. At this point I can't solve that problem. I encourage you to solve the problem. Not by telling other people to start over, but if you think its necessary to do so by proving it by starting over *yourself* and coming up with a design that is obviously better. Show a valuable idea, and people will jump onboard. Isn't that waht open source is all about?Its obvious that the choice of hydraulic drive is a sacrifice of performance and efficiency for simplicity, enabling people to build the GCVS set without the ability to create large iron castings and machine transmissions.On the other hand, acknowledging the need to initially buy tools like a lathe and mill and hydraulic motors is accepting the need for some capital.So both and neither. We're going to buy some tools, and we're also going to try and keep our designs simple so you can create a tractor out of standard steel stock, rather than requiring large castings and precision gear machining.The visualization that I think makes the most sense is thinking "We want a fully fleshed out owner of the GVCS to be cable to create tools and precision-enough parts that will in turn enable another group/site to create a fully fleshed out GVCS tool set" - GVCS should be its own parts supplier when its complete. Understand?

-

If your wife gave you permission. I would like to know if she has a sister for me.. LOL. I need to change the brake.How much do you play up for permission??

-

Towards 50 GVCS Tools by 2013...... ?

Is that still realistic? About 45 machines still have to be done, with 3 prototypes each accounts for 135 prototypes in 110 weeks. 1.25 prototypes each week !

The current manufacturing rate at FeF is a magnitude lower. And everyone at FeF busy with construction of Hablab and shop, with difficulties in construction and deficiencies in quality. (-> DavidIam and Harold_V)With that given situation, I believe now gregors statement is very realistic:

Whatever, if they want to be that arrogant they can wallow in it. It will take years and years to complete the GVCS and when it is done it will suck because there will simply be very little knowledge and experience behind it.So, who still hopes for 50 GVCS in 2013 ?

Mike

-

people in Russia say hope dies last

@dorkmo

Yes, with parallel development it could be possible. Using alll the expertise from volunteers on the web. And with an well equipped and staffed production shop for realizationBut from current FeF strategy I don't expect much until 2013.

Mike

-

@Bastelmike - Mike, it is just painful to watch you trying to convince the "happy folk" that massive changes would need to occur before anything OSE plans to do can ever happen. Changes from the top down I'm afraid. Why waste your precious breath?

Those that have the technical knowledge stand no hope of convincing the eternal optimists amongst us. They just need time to digest the gravity of the situation.

My advise? Relax. Either stand back and watch the circus and wait for the day when OSE control is transferred to mentally stable people, or take your knowledge and skills elsewhere. Form a small local group of your own for that matter. I've been reading many of your posts and you are very talented. I'm sure you could pull it off.

I would be willing to support you in such an endeavor.

Dawg

-

@Bastelmike > But from current FeF strategy I don't expect much until 2013.

Actually, there is very little historical evidence that suggestions that serious progress can be made on the GVCS in the next few years, if ever. If you look back into the wiki, you'll discover past attempts at GVCS-50 development efforts that reached a certain point (usually an initial design) and then were dropped. This happens over and over again. Note, for example, that there as been almost no word on the dimensional saw mill of late. The project hit a set back and likely has been abandoned. This is a recurring pattern at this point.

Dawg's suggestion is a good one - either sit back and enjoy the show, or figure out a way to do it independently.

- Mark

-

@mjn

The last I have heard of the dimensional sawmill is one prototype being build by Schwaiger shop...

But its a good example anyway. People who talk about building a precision metalcutting CNC multimachine aren't able to build a wood saw. Bigger it can't be the gap between talking and doing!

I've already build several wood saws, circular and bandsaw type. Its not so difficult, and no real big step to convert a large bandsaw into a sawmill. So why isFeF unable to do so ?...

Mark, if You look in those forums of model builders and see what perfect working models of eg. steam locomotives people build in their homeshops and the result of FeF in a year, there seems something to be wrong

Presently I too think Dawg's suggestion is good, just look how they struggle... Though I will occasonally comment on those things going on with OSE and FeF; it doesn't cost me more than a bit of time

Mike -

@Dawg

You are prob right, if You think it's not possible to convince those "happy folks". But maybe its worth some trying if it doesn't cost you more than a bit of your timeI like the basic idea of open source hardware like the GVCS. I would regret that idea demolished by mismanagement.

But, as mjn wrote, realize it independently is impossible. First you need a machine factory to do that. Something FeF ignored and came to no results that way. Second, to realize the GVCS 50 needs 30,000 or 50,000 man hours - more than the rest of my work life. So a one-man-show is no alternative either.

OSE had already build up the needed infrastructure to do it. It was known on the web. It had already acquired some funding, not enough, but more than a start already had been achived. And with FeF they had got a place to realize it.

It's really bad that OSE top management has not been able to get a medium-level management to realize it. Perhaps it was always was to tempting for Marcin to overrule his mid-level managers until noone competent left.Remains just personally for me the question, where are other bether managed open source hardware projects ??? Suggestions by PM welcome....

Mike

-

To BastelMike:

I've (recentely) been to FeF. I am pretty sure what happened to the dimensional sawmill project, because I think I witnessed its demise at the team culturing meeting I attended while I was there. I doubt that anyone else there saw it that way, though.

There was a buzz & excitement, because "all they needed to do was to buy the blade", and there was a flurry of internet searches to find a source for a 30" diameter insertable-tooth sawblade.

I pulled out my Blackberry, and joined in the search, only going about it in a slightly different fashion than the rest. I searched for suppliers for any such saw blades, not for 30" anything. I found several manufacturers who sold saw blades, but 30" isn't a standard size for them - I think the standard sizes start at 42". I showed the list of standard sizes to Marcin at the table.

I don't know if anyone else realized it, but it dawned on me that all of the design work that they may have even paid someone else to do for them on a 30" blade saw mill was now down the drain, and it would have to be redone from scratch if it was to ever see the light of day. I think that I also pointed out to someone else on the site the next morning that they don't really have enough trees on site to even begin to recover their costs by cutting their own lumber, and the ones they have are generally too small...

Marcin isn't consulting with subject matter experts before diving into much of anything, and then he doesn't seem to like it when he's told later in, that he should've "made a left turn at Albuquerque", so I left with little hope that any further contributions would amount to anything useful.

So, sitting back and enjoying the show seems like good advice, unless you've got better things to do ;)

-

> Suggestions by PM welcome....

It sorta depends on what you are after and what your beliefs are. @Dawg is putting together a nice collection of web tools over at Open Source Resilient Living. It's slanted more towards self sufficiency, which isn't going to appeal to those interested in building post-money communities. Still, some of the projects emerging are interesting - including a manual CEB tool. Electronics are not really the focus of the GVCS, but if you want to work on an open source toaster (etc), there are plenty of OS electronic sites that would welcome you. You might even get published in Make Magazine. There are metal working sites, farming sites, wood working sites, and many other open source projects. Some might meet your needs.

The approach that I have taken is to create my own site and pursue the projects of direct interest to me. This is almost trivially easy to do with something like Google sites. I have my Phase 3 Project site, where I have documented some of my past farm projects. I also have sections that deal with research topics - like steam engine valves. I have to say, that it's inspirational (at least for me) to have complete freedom over my own projects. I use documentation conventions that I feel comfortable with. It's also on my schedule - not someone else's.

Finally, I would comment on other sites to build a set of tools that would enable the creation of a village-sized economy using permaculture principles for food production, local resources for building, and it's own fablab for producing what ever else is needed. There are none. Based on my research, OSE is unique. Marcin's vision is a very powerful one, full of hope and possibility. This forum, the OSE wiki, the blogs, etc. were all created to pursue this vision - one that I find very attractive, personally. This puts us in something of a bind, because Marcin really lacks management skills. It is a double bind because he controls (and will continue to control) the financial resources coming in. To some extent, that is completely fair. He personally raised the money, so he should get to say how it is used.

The flip side of that argument is that Marcin is also trying to build a community. Some of those contributions come from True Fans - like me. In a good community, leaders listen to the voices of the group and lead them based on that input. If the community has no input into the overall direction or the leader in control routinely ignores it, then OSE is little better than a cult based on Marcin's vision. Marcin has gathered control solely onto himself, which means that it's ultimate success or failure rests in his hands. It is possible that he will succeed. It's even likely that we will see some of the GVCS slowly emerge out of the inefficient process that he uses, but it will be a long time before we see all of it come to be without some significant change in the way things are being done.

So the choice is yours, @Allen15. If you want to further the concepts we share in, find a way to do it. If OSE puts barriers in your way - find or make another site. I would urge you to hold to open source values, as we will all benefit from it.

- Mark

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Allen15 November 2011

- Bastelmike November 2011

- Conor August 2011

- DavidIAm October 2011

- Dawg November 2011

- dorkmo November 2011

- DreamBuilder October 2011

- gregor September 2011

- Howard_V_Agnew November 2011

- Metz November 2011

- Mike_Apostol November 2011

- mjn November 2011

- spike September 2011