-

I recently started a topic about the top priorities for bootstrapping the GVCS here:

http://openfarmtech.org/forum/discussion/227/bootstrapping-the-gvcs-priorities

I believe the XYZ table is one of the most key components here. I'm not sure what the plans are, but it seems to me that this single xyz table could be:- * torch table

- * laser cutter table

- * cnc router table

- * 3d printing table

There is already a wiki page started for the XYZ table:

http://openfarmtech.org/wiki/XYZ_Table_Concept

I'd like

(1) for it to be updated with what the team is currently using, if what they're using is worth documenting (might be a "lessons learned" type thing and not worth documenting), and

(2) for a lot of brainstorming on the wiki as to how we can come up with the best common platform for our needs.

Also, lets keep in mind this table with have to mate with the stepper motor and stepper motor controller, for example, motors must be sized properly. I've been doing a lot of research on the motor controller side. Check it out here:

http://openfarmtech.org/wiki/Stepper_Motor_Controller

I nominate the XYZ table, motors, controllers, and controlling software as "top priority" right now. Of course I'm not actually on the farm and don't know what real-world challenges are being faced, but it seems like the table is key.

-

10 Comments sorted by

-

One small point. All the functions you list there do indeed go together except for one, the router. A router actually comes into physical contact with the material being formed. This is a totally different beast than a torch table on many levels. It needs to be several times more rigid for one thing. So relatively heavy. These are attributes you try to avoid in a torch table.

A CNC router should be a totally different machine from the start. MUCH heavier frame, servo motors instead of steppers, proper linear ways, ball screw drives, much longer Z axis and a very flat table.

The Dawg

-

Good feedback Dawg. Depending on what turns out to be feasible, a two-table system may be the way to go. You'd definitely need to reduce the gear ratio to increase precision and torque for a cnc machine. However, I don't think a cnc routing machine is as daunting as you suggest. Here is a 19"x20"x5" routing cnc machine, based on stepper motors:

http://www.k2cnc.com/shop/proddetail.asp?prod=KT-1414-09&cat=26

"The new

KT-1414-09 has 20mm shafts, antibacklash nuts, wider 19 inch material

capacity. Use the accurate machine to cut thin aluminum, plastics, and

wood. The anti-backlash nut and the .100" pitch leadscrews provide very

accurate resolutions and is great for fine inlay work. The pitch and

high torque combo also provides great mechanical advantage when cutting

hard woods and have been tested to cut .375" deep, at 70IPM, with a

.375" diameter bit. The frame is comparable with Nema 23 motors or K2

servo motors. With the right approach in your toolpaths, spindle, bits,

accessories you can achieve results in milling that once required a

$50,000 and more cnc machines. With the KT1414-09 you now can do this in

your own garage, business, or anywhere with 110V outlet."

+ Backlash:

0.0005 inch

+ Resolution:

0.00025 inch

Cost for that setup is around $2500.

They've also got bigger machines as well:

http://www.k2cnc.com/shop/products.asp?cat=26

Another thought, what if we used the same cnc routing machine to create a cnc lathe as well? You could maybe remove the bottom and have a lathe where the workpiece is normally.

-

You are correct, there are some machines designed to use steppers. But steppers will only get you so far. Where as servos are considered a proper industrial component.

Here is another example of a good but slow milling machine using steppers as you have stated:

http://www.tormach.com/

And here is a much more heavy duty machine (still a hobby machine) using servos:

http://www.ihcnc.com/

One issue with steppers is they tend to have no encoders with them. The reasoning I guess is a stepper is a cheap digital motor already, why add another digital element to it. Without this encoder there is no positional feedback. We call this an open loop system. You tell the stepper to go here and you assume it went. There is no way to know if it did or not. If your design is well matched to the loads present, then you'll probably never lose position.

On the other hand, servos are basically a brushed DC motor with a digital encoder coupled to it's shaft. The drivers for these motors include a closed loop system that constantly monitors the motors position. It can't lose its position. If it gets overloaded it trips an alarm and stops so you know there's an issue. There are other reasons why I think a servo is better, this having to do with torque curves.

They are more expensive however, so if you can make do with a stepper for light duty or slow work then do it. For the torch table, as long as we have no need to go fast, steppers are the way to go. Well, a torch can only cut so fast anyway, so perfect.

K2 machines are very light duty. They are only useful for routing wood and plastics. Yes, I know they say they can machine non ferrous metals but trust me, they really can't do it effectively. Then we get into trying to machine steel, then forget it.

When I say effectively I mean it should be able to proceed without over stressing itself to the point of damage. Also, it should be able to machine the material in a timely fashion. No point having a machine that has to take tiny tiny nibbles and take all afternoon to machine a part when a proper setup can do it in 15 minutes flat. This is not an exaggeration either. Then on top of that, if after a few months you realize that the machine is self destructing, you realize that the manufacturer was not really being totally honest.

Lets just make sure we are comparing apples with apples....:)

Also, I hate to be poo poo'ing but very few multi machines I've seen work anywhere as good as their single function counterparts. As long as we realize that a multi function machine is a compromise then great.

The Dawg

-

Honestly, in the long run, the hardware might end up being the easy part to resolve.The software is turning out to be quite a bottleneck. With every fabrication tool, different techniques have to be applied for fabrication (which each have their advantages, disadvantages, quirks and issues).We're diving down into the GCodes right now to get our torch table running, and at the moment our software pipeline is slightly on the evil side. It's one thing when we've only got a few parts to handle at a time, but in the long run, we really need a better approach.Still, an uber-xyz table has a lot of allure in being able to combine multiple pieces of equipment with just a head to change things out. We are keeping this option in mind for the long-term. In the short-run, we're just trying to get single productions runs of the torch table working reliably, then we start scaling it out/up.One idea that would be epic in the long run is getting some Willow Garage ROS tech running some overhead gantries to move pieces automatically between machines... but that's a ways off :D-Chris

-

@ FactorChris - Well, I feel your pain my friend. CNC programming is one of my professions. It is not something we're ever going to be able to "print". There are way too many variables involved. I'm compiling your next packet of goodies and I'll include some of this topic.

If I was there with you I would have that thing screaming in a few days. But I also have many thousands of dollars worth of software to aid me and years of experience as a guide. I have some serious reservations about this Gcode converter. I'm not sure it's the way to go.

If you guys have a vector you need converted to Gcode, send it to me. I will ask a bunch of questions and then send you something to chew on.

But go through the links I'm going to send you now because I have a message I sent to Marcin a while back that deals with this very topic.

The Dawg

-

@ Jason - Actually I was referring to links to messages on this forum. But if there is any reference material you need on this topic I could try and send it your way. I have access to a lot of downloads.

As far a conversions, it's not like an export filter in Photoshop. I take the vector into a CAM environment and set all sorts of parameters to explain how I want the machine to move in relation to this path. So the vector is really just the very beginning. Also, after I've got a tool path generated in this environment there is yet another layer called post processing. This takes into account any special machine dependent codes that change from one controller to another.

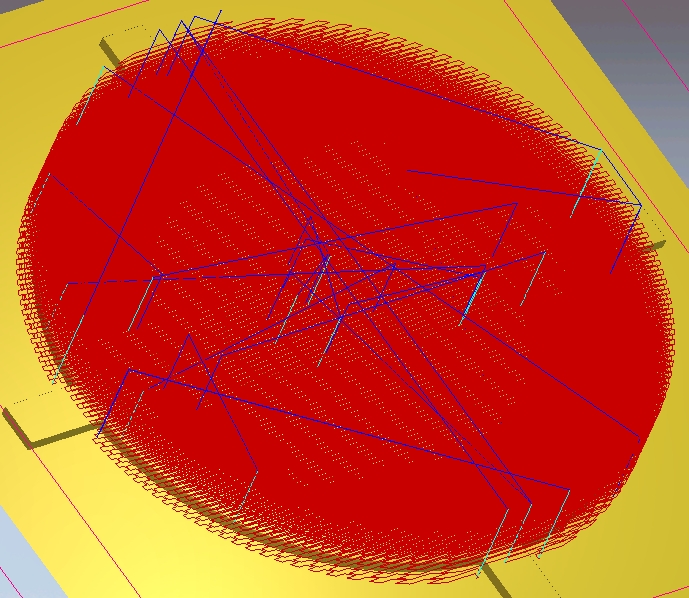

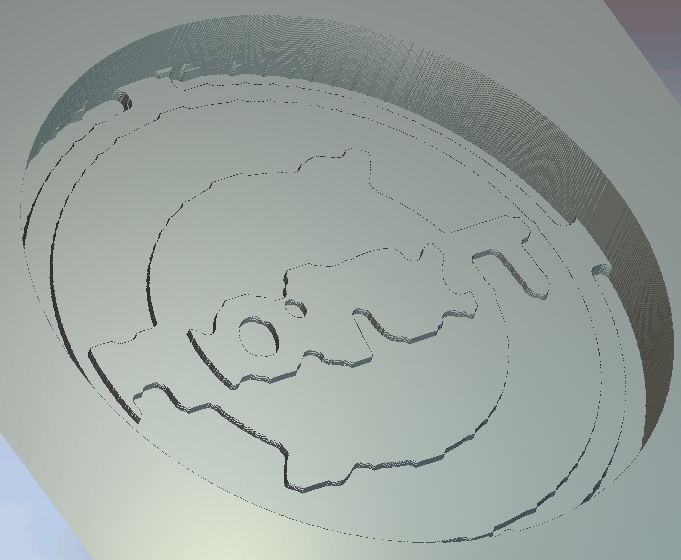

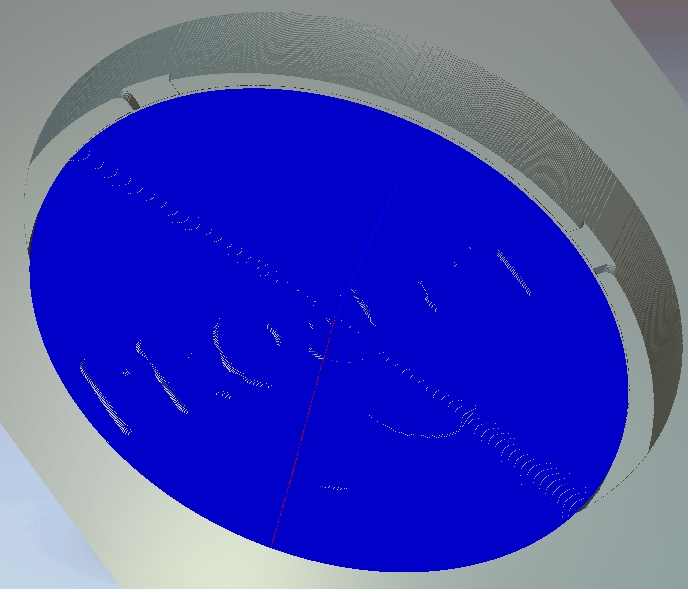

I just went through my old projects and took some screen captures to illustrate what I'm talking about. Hopefully you find this interesting.

I have a series of images below that go from a set of vectors (lines) to a finished cut simulation.

First file is the vectors.

Second is the 3D model

Third is a complex roughing tool path (the red lines)

Forth is a simulation of the path as it would look in the milling machine.

Fifth is the final tool path.

Sixth is the final simulation.

Now this is quite a bit more complex than a torch table tool path. But many of the same considerations come into play.

The Dawg

Attachments

p01.jpg 62K

p02.jpg 136K

p03.jpg 287K

p04.jpg 141K

p05.jpg 129K

p06.jpg 183K -

Jason wrote

I believe the XYZ table is one of the most key components here. I'm not sure what the plans are, but it seems to me that this single xyz table could be:

- * torch table

- * laser cutter table

- * cnc router table

- * 3d printing table

I think it would make a lot of sense to have as single xyz table platform. There could be perhaps two sizes of the same basic design: larger for the big stuff, and small for the precision stuff.

Basically I think its a good idea. A common base could be used for torch, plasma and probably for laser cutting too. As Dawk said, using it for a router or 3d printer might create a lot of problems. Maybe the necessary size of the table makes already the difference. For cutting, laser, torch,plasma, you need a machine large enough to handle commercially available sheet sizes. Don't know the US dimensions, Dawk might help here, but in Europe most sheets range in size from 1,25x2,5 m to 2x4 m. A cutter has to be this size and therefore it doesn't make much sense to use it as a router too.

But combining torch and plasma is already available in commercial machines. Adding a laser as an option will prob pose no big problems, therefore an large XY-Table could be designed for torch, plasma and laser cuts.

Mike

-

Watercutting makes sense, as you cn cut materials that cant or shouldn't be cut thermically. But what about corrosion? Using stainless materials just because of occasionally watercutting, is it worth the cost?

With standard designs of these machines the table is open to the floor, so I woudn't recommend water on them....

Mike

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Bastelmike August 2011

- Dawg May 2011

- FactorChris May 2011

- Jason May 2011

- mjn August 2011