Visit the forum instructions to learn how to post to the forum, enable email notifications, subscribe to a category to receive emails when there are new discussions (like a mailing list), bookmark discussions and to see other tips to get the most out of our forum!

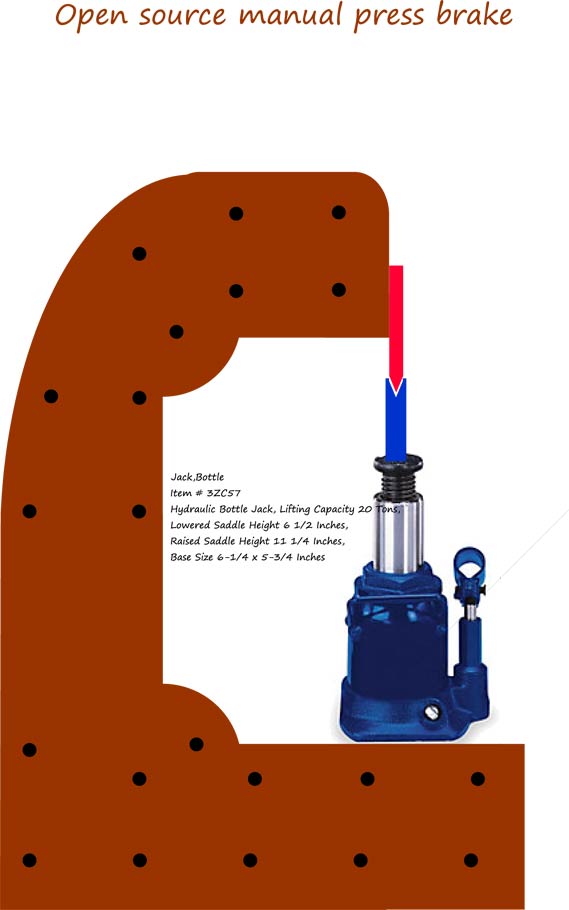

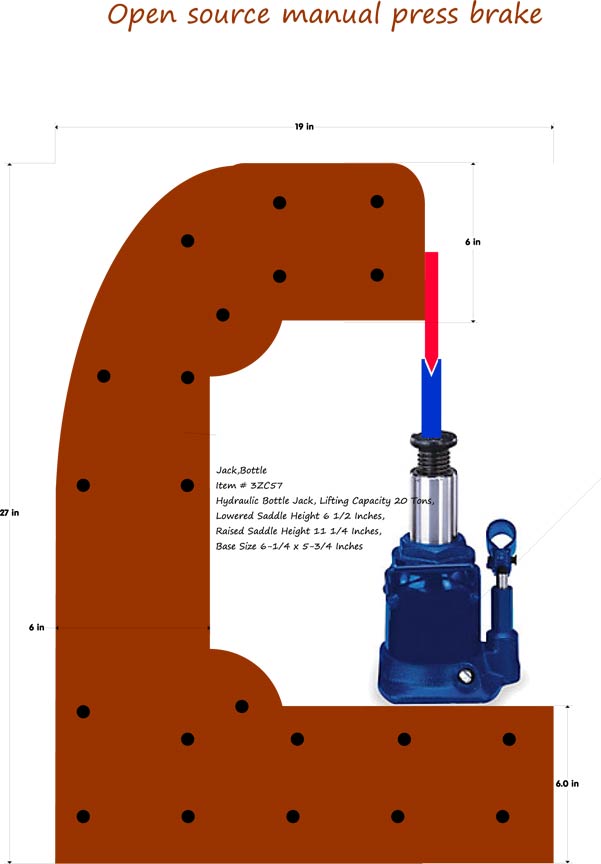

Open source press brake

-

I am in need of a press brake for my stoves so I am working on a design. It is like the large Hyundai press brake next door in that I can bend square tubes and open on the sides unlike the usual shop press conversions.

Specs are 50 ton manual bottle jack, 24 inch length with changeable V blade to make box bends in steel plate.

Target is bending more than 90 degrees with a consistent radius not too sharp but not too round either.

I would like to bend at least 6mm plate with it.

Materials are 2 sheets 5mm plate, high strength bolts, 50 ton bottle jack, hardened steel bending tooling fabricated at the tool and die shop up the street.

The design will be a C clamp shape with 2 arms. I will cut that part on the CNC. Each arm will have 3 layers of 5mm plate with the arms separated 1-.1.5 feet and cross braced.

It will have minimum of total 15mm x 12 inches thick steel plate total to carry the load at all parts of the C clamp shape. Basically it is a giant c clamp with a press brake blade in it.

The projected build cost is about $350-400 dollars including powder coat. -

4 Comments sorted by

-

Here is a side view. the black circles are bolt holes for the laminated steel plate. 3 layers 5mm steel plate bolted together similar to a master lock.

Total of 2 pieces cross braced, cross braces attached at the bolts. No welding in this design.

Attachments

prototype-press-brake.jpg 31K

prototype-press-brake1.jpg 32K -

Here is the specs for the dies. got the cost quote back from my tool and die place. Almost 280USD. I speced it with tool steel. I am wondering if I can get by with case hardened mild steel, or buying a pre-made chinese die.

Attachments

press brake die specs.pdf 618K

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Metz October 2012

Loading