Visit the forum instructions to learn how to post to the forum, enable email notifications, subscribe to a category to receive emails when there are new discussions (like a mailing list), bookmark discussions and to see other tips to get the most out of our forum!

Greeting From Huntsville Ontario, Canada

-

Warmest greetings!

I am so pleased to be a new member of this forum and online community. My name is Danial, Im 27 and have been fascinated with society and the way we operate and build things since I was quite young. It wasn't until the last couple years that I became familiar with the concept of open sourcing and that has ultimately brought me here. I am currently in the initial stages of designing a basic solar glass foundry. The intention behind this is to bring a low cost, low energy, low carbon footprint glassware technology to the community that can be used to produce everyday glass items used in the home and greater community.

I have no formal education and am not the most tech savvy person out there, but I love to build things. Over the past three years I have built a cob meditation building and started a community gardening project to provide fresh produce for the local food bank on unused building lots. I'm very excited to have found this group of enthusiastic individuals and I look forward to getting to know you!

Peace!

~Danial

-

6 Comments sorted by

-

Great that you could join us Danial! Always good seeing fellow Canadian's working on OSE :DCheers,- Mike

-

Hi Mike! Nice to meet a fellow OSE Canuck!

Hi DavidIAM! Cob is amazing to work with! Here is a photo montage of the construction process if you like:

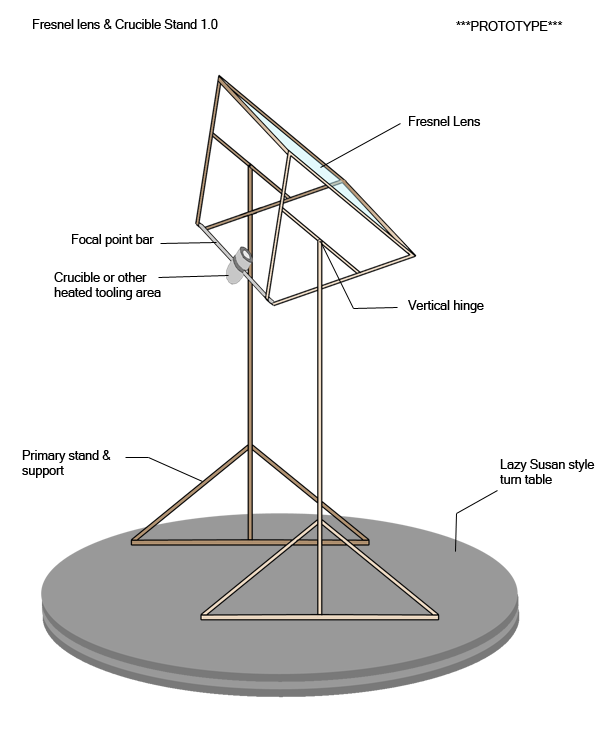

I have several very basic computer drawings done of the solar glass foundry. I rather use the good old pencil and paper for drafting so my technical drawings on the computer suck lol. But below are a few of them. I'll be doing a video of the process soon and I'll post it. Because the winter is not conducive to outdoor testing all I can do is plan, draw, and build right now. The testing will start in the spring. I am working on a scale model now with a 7"x10" fresnel lens to help work out some of the design flaws.

Right now Im designing the frame for a fresnel lens that would have adjustable focal length, making it easier to get the desired temperature. Im also trying to get a modular setup so that the crucible could be changed out for a glory hole, annealing oven and so on. Im just starting the whole process and the attached drawings are also very basic. They will get more detailed soon.

I also have drawings for a set of stacking forms to be used in chunk casting, Ill post a video of them when I get a chance to put it together.

Oh, and a sun tracker will be incorporated, its just not shown on the drawing.

Peace!

AttachmentsFresnel-Crucible stand side profile1.PNG 28K

Fresnel - crucible stand perspective 1.png 69K -

i drew up a quick sketchup if anyone wants to play around

-

Very interesting - on both the cob building, and on the solar melter. Have you done any calculations on the amount of energy intensity required to raise a crucible and material to glass melting temperatures, vs. its ambient heat dissipation rates, vs. the amount of energy available from a mere square meter of sun?

-

@ dorkmo - That model is really neat. Im going to have to learn to use sketchup. It makes it look so much cleaner. Thanks for drawing that up!

@DavidIAM - I know that there is roughly 125 watts/ft2 (1353watts/m2) falling to earth under "ideal" conditions. The conditions Ill be working in will be far from ideal between the latitude here in Huntsville and our generally cloudy weather. I may have to ask around at the local environmental studies university here to get some more accurate numbers, or try to figure it out on my own. I think Im going to have to start pouring over some physics texts to get a grasp on the math needed for a lot of the thermodynamic variables involved with this as I'm pretty illiterate with them.

I am going to be starting my testing with a low melting point glass like soda-lime glass to try work up from there. Ill be starting with recycled glass as well as it will give the best chance for success. I know there are lenses large enough to melt silica sand very quickly, it is a matter of taking that and doing something useful with it, like melting a 5lb crucible full of it for casting.

I have been considering the crucible as well. A traditional crucible would be terribly inefficient to use for this. It is traditionally placed inside a hot place where as in this instance the hot place will be inside of the crucible only. In a way the crucible is the furnace as well and will need to be designed to function as both. I am thinking of an insulated spherical crucible, but that is a ways off yet. I have rough set of drawing for it but I'm not focusing on it until I have the lens stand fleshed out.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Danial December 2011

- DavidIAm December 2011

- dorkmo December 2011

- Mike_Apostol December 2011

Loading