-

GEARTURBINE PROJECT

Atypical InFlow Thermodynamic

Technology Proposal Submission

Novel Fueled Motor Engine Type

*State of the art Innovative concept Top system Higher efficient percent.

Have similar system of the Aeolipile Heron Steam device from Alexandria 10-70 AD. -New Form-Function Motor-Engine Device. Next Step, Epic Design Change, Broken-Seal Revelation. -Desirable Power-Plant InnovationYouTube; * Atypical New • GEARTURBINE / Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Thrust Way Type - Non Waste Looses

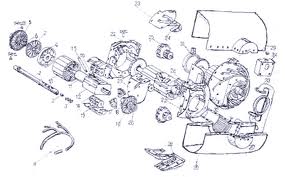

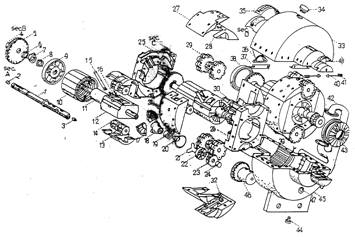

-This innovative concept consists of hull and core where are held all 8 bteps of the work-flow which make the concept functional. The core has several gears and turbines which are responsible for these 8 steps (5 of them are dedicated to the turbo stages). The first step is fuel compression, followed by 2 cold turbo levels. The fourth step is where the fuel starts burning – combustion stage, which creates thrust for the next, 5th step – thrust step, which provides power to the planetary gears and turbines and moves the system. This step is followed by two hot turbo steps and the circle is enclosed by the final 8th step – bigger turbine. All this motion in a retrodynamic circumstance effect, wich is plus higher RPM speed by self motion. The Reaction at front of the action.

*8-X/Y Thermodynamic CYCLE - Way Steps:

1)1-Compression / bigger

2)2-Turbo 1 cold

3)2-Turbo 2 cold

4)2-Combustion - circular motion flames / opposites

5)2-Thrust - single turbo & planetary gears / ying yang

6)2-Turbo 2 hot

7)2-Turbo 1 hot

8)1-Turbine / bigger

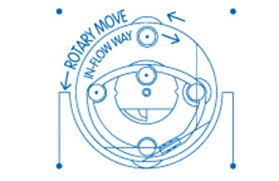

-With Retrodynamic Dextrogiro vs Levogiro Phenomenon Effect. / Rotor-RPM VS InFlow / front to front; "Collision-Interaction Type" - inflow vs blades-gear-move. Technical unique dynamic innovative motion mode. [Retrodynamic Reaction = When the inflow have more velocity the rotor have more RPM Acceleration, with high (XY Position) Momentum] Which the internal flow (and rotor) duplicate its speed, when activated being in a rotor (and inflow) with [inverse] opposite Turns. The Reaction at front of the action. A very strong Novel torque power concept.

-Non waste parasitic looses for; friction, cooling, lubrication & combustion.

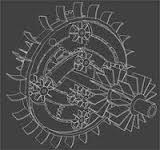

-Shape-Mass + Rotary-Motion = Inertia-Dynamic / Form-Function Wide [Flat] Cylindrical shape + positive dynamic rotary mass = continue Inertia positive tendency motion. Kinetic Rotating Mass.

-Combustion 2Two continue circular [Rockets] flames. [ying yang] opposite one to the other. – With 2TWO very long distance INFLOW [inside propulsion] CONDUITS. -4 TURBOS Rotary Total Thrust-Power Regeneration Power System. -Mechanical direct 2two [Small] Planetary Gears at polar position. -Like the Ying Yang Symbol/Concept. -Wide out the Rotor circumference were have much more lever [HIGH Torque] POWER THRUST. -No blade erosion by sand & very low heat target signature profile. -3 points of power thrust; 1-flow way, 2-gear, 3-turbine. *Patent; Dic. 1991 IMPI Mexico #197187 All Rights Reserved. Carlos Barrera.

-

3 Comments sorted by

-

State of the Art / Novel Rotary-Turbo-InFlow Tech / Featured Development - GEARTURBINE PROJECT Have the similar basic system of the Aeolipile Heron Steam Turbine device from Alexandria 10-70 AD * With Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Way Power Type - Non Waste Looses *8X/Y Thermodynamic CYCLE Way Steps. Higher efficient percent. No blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dic1991 Atypical Motor Engine Type

Attachments

gearturbine draw.jpg 10K

Gearturbine Isometric Patent Draw Hand Made.jpg 19K

gearturbine retrodynamic effect rotary move vs inflow way.jpeg 9K

Gearturbine inside view colores.jpg 4K

Gearturbine Frame Lines Isometrico.jpg 5K

Gearturbine front view.jpg 2K

Gearturbine back view.jpg 3K

Gearturbine Periodico El Norte Newspaper.jpg 14K -

Dear Retrodynamic,

thanks for sharing this info. After reading your post one time it has not become fully clear to me how exactly your turbine works or what its main advantages are.

From the state of the drawings I assume it exists as of now only on paper or in CAD without a working prototype.

To compare the advantage of stationary thermodynamic engines with other existing ones usually the efficiency is given which is the ratio of in-going chemical energy and out-going useful mechanical energy. Sometimes it is given as grams of fuel per kiloWatts of power and per hour of operation.

For mobile application in addition the ratio of the engine mass and maximum constant mechanicel power is useful since here one would like high power with low weight

And then of course the price of such an engine as an absolute value or as cost per kiloWatts is compared as well.

And in today's attention to environmental friendlyness also the portion of damaging exhaust gases is of interest like NOx, COHx, CO, etc. CO2 is not important if biofuels are used.

If these values are given (measured not calculated) then this engine could be compared with the state of the art without understanding all internal details.

The common advantage of gas turbines are their low weight per power output.

The common disadvantage of gas turbines is their relatively low efficiency which is usually significantly lower than turbo-diesel piston engines. The reason for that are mainly friction and leakage losses of the high speed and high pressurized gases.

And usually the price of gas turbines is very high compared to piston engines because the turbine blades need complex shaped surfaces for their aerodynamic efficiency and must be made of creep and heat resistant high performance materials.

And then in this OSE-community another criterion is important which is simplicity of manufacturing such that it can be produced in a village type community and does not require large industries.

Based on these considerations it seems doubtful whether this turbine will be an advantageous proposal for the OSE community. However, I would be pleased to be proven wrong.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

- Jason265 February 2015

- retrodynamic November 2014

- roleic November 2014

Tagged

- energy 15

- design 6

- engineering 5

- mechanical 2

- technology 2