Visit the forum instructions to learn how to post to the forum, enable email notifications, subscribe to a category to receive emails when there are new discussions (like a mailing list), bookmark discussions and to see other tips to get the most out of our forum!

Biomass Gasifier/hot-water-furnace Plans now Posted

-

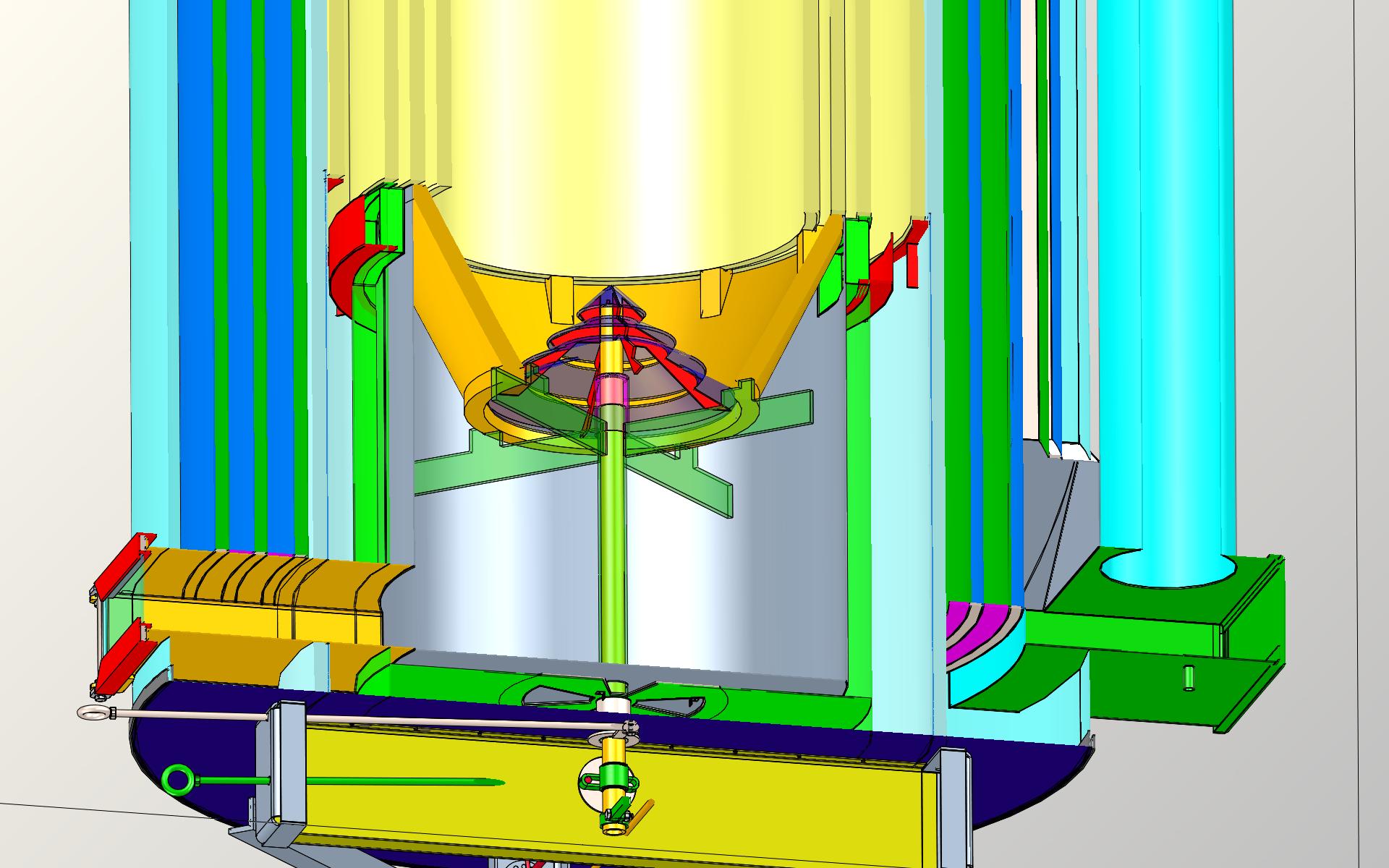

Plans are for a large household size, 110,000Btu/hr, 32kWh, which will heat water for heating needs and generate electricity through a genset fueled from the gasifier, posted here.

This design is the culmination of my 38 years of work in the field, and I think it will solve many of the problems that now plague those modeled after the old WWII Imbert gasifiers. While many recent improvements have been made by dedicated gasifier enthusiasts, it is still an evolving technology, with much scope for new approaches and improvements in the utilization of huge quantities of locally-available waste biomass fuel sources. Biomass- and waste-fueled energy has the potential to contribute much more to global green energy demands. To learn more on this subject, read my Department of Energy report on “Biomass Energy, State of the Technology, Present Obstacles and Future Potential” at

http://www.fundamentalform.com/html/doe_report-1.html

I have finally achieved an optimized gravity flow design that follows more elegant thermodynamics than previous approaches, through a labyrinth of concentric shells and spiral ducts. It thrills me to give the complete set of plans for this new household energy system to you, that you might build and test one and give me feedback in order to improve it, that more local waste products become clean efficient energy.

Actually, since this is a radical take-off from previous prototypes, I don’t know how much energy Roundy will put out in practice……could be substantially more than 32kWe, especially when connected to a powerfully-sucking engine as a gasifier. I expect a very large turn-down ratio, at least 20/1 in combustion mode, with very high efficiencies in condensation mode, perhaps 95% of the High Heat of wet fuels (most furnaces are rated at Low Heat efficiency, since they don’t condense the moisture to get back the heat of vaporization. Since green biomass can often be half water, and half of the dry fuel gets thermally converted to steam, this represents a significant increase in energy available from condensing the woodgas or exhaust).

Since this unit has not been built yet, I don’t know the performance parameters it will exhibit in actual operation, but I expect it to create a high quality gas, clean enough after the condensing heat exchanger (CHX) for the engine without further cyclone separators or filters. There will be an operating range where the gas is the cleanest, and another condensing range where efficiencies of both gas and hot water production are highest. These parameters will have to be tested to know for sure.

If you are interested in the principles behind this design and gasification/combustion/heat-exchangers, I highly recommend reading the introduction, which is in the Gasplans2.zip file located at http://opensourceecology.org/wiki/Gasifier_Burner_with_Heat_Exchanger_Prototype_I#Update_2.8.12 or simply read it on my webpage at http://www.fundamentalform.com/html/biomass_gasifier_breakthrough.html

I hope to get you fired up to build one, as I will be doing here on Whidbey Island, Washington. I will also be posting videos on the details of ongoing fabrication, and will be moderating discussions on this Gasifier Burner Forum ~ Welcome to the Forum!

Attachments

3D section1.jpg 205K

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

Loading