Visit the forum instructions to learn how to post to the forum, enable email notifications, subscribe to a category to receive emails when there are new discussions (like a mailing list), bookmark discussions and to see other tips to get the most out of our forum!

Manual CEB Press (Category 1) proposal

-

I'm thinking a much simpler CEB press could be beneficial in the pursuit of a manually operated version. A Category 1 design. Heck it might even be a good idea for the existing one.

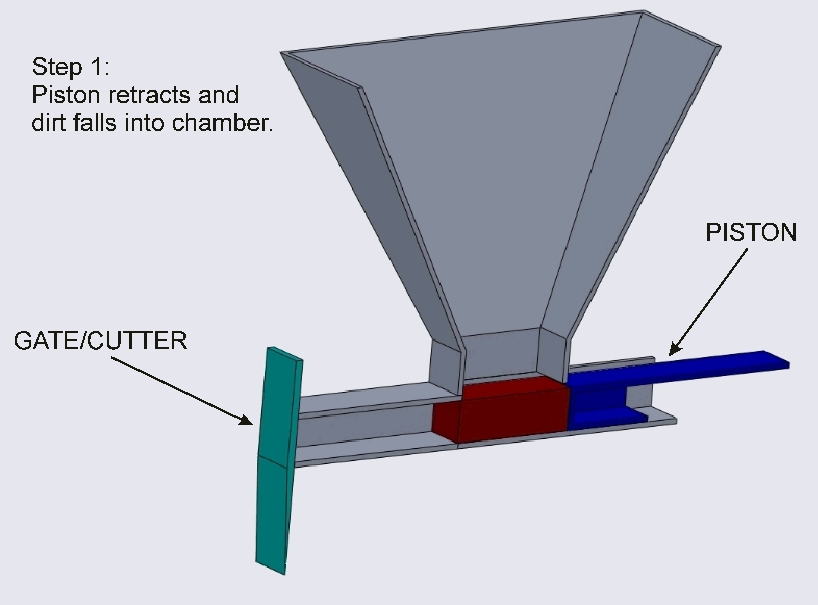

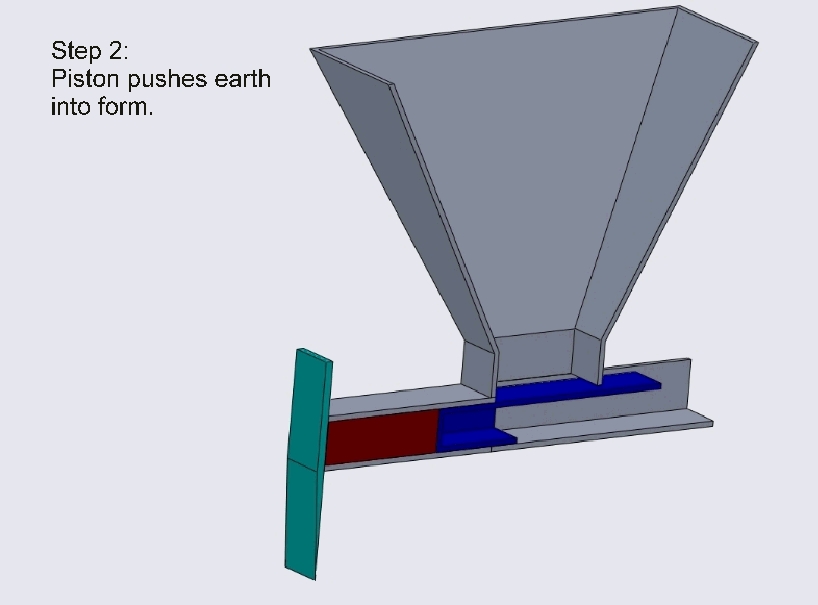

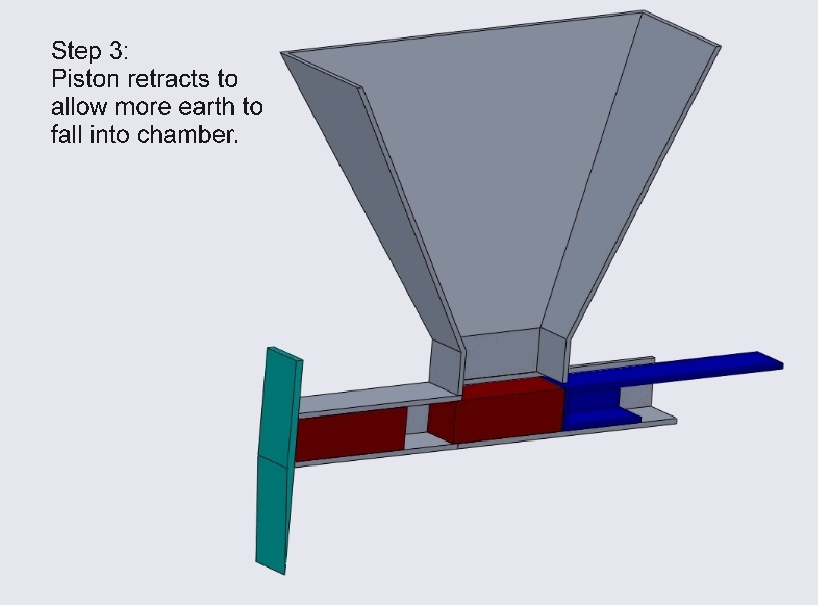

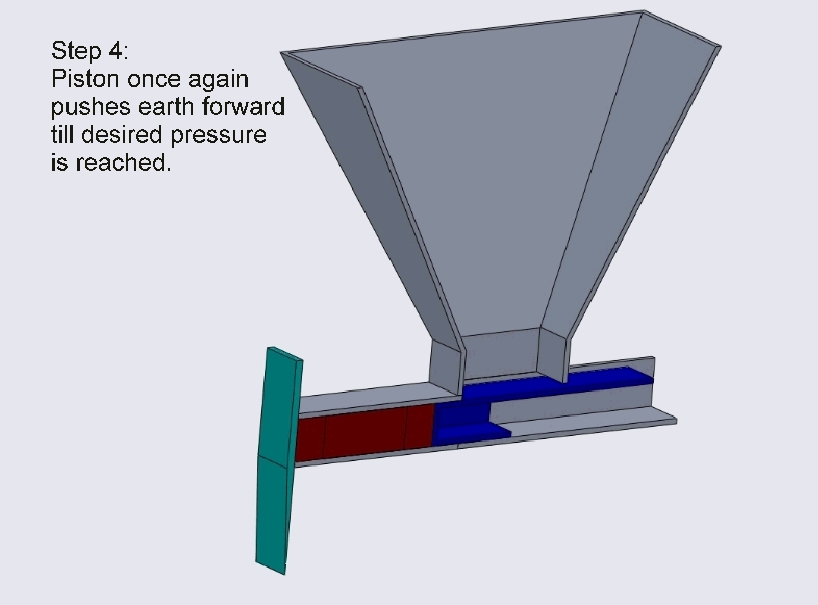

I am proposing a process that uses only one piston. This piston would be horizontal. It would open enough to accept some dirt from above then push that dirt into a form or a tunnel. This tunnel would be shaped in such a way to continuously extrude long thin brick material. The tunnel would be approximately 2 bricks long.

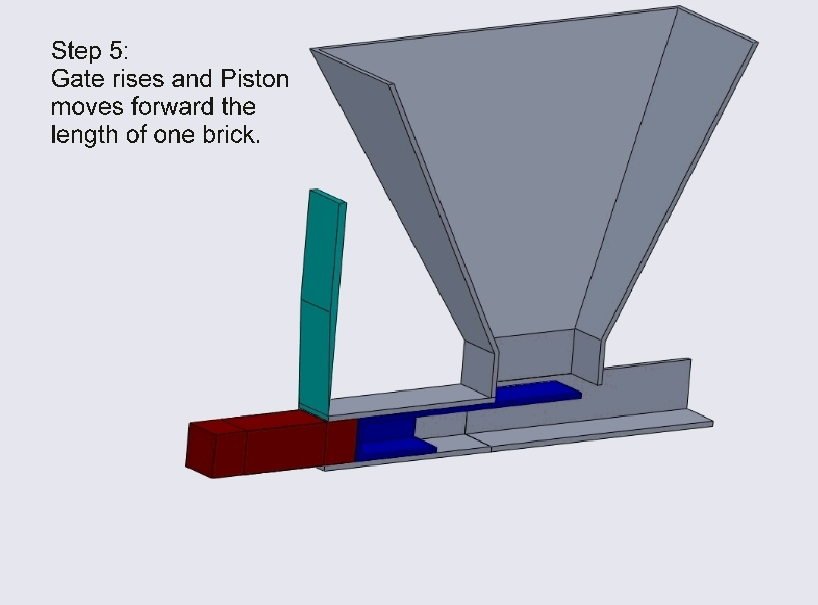

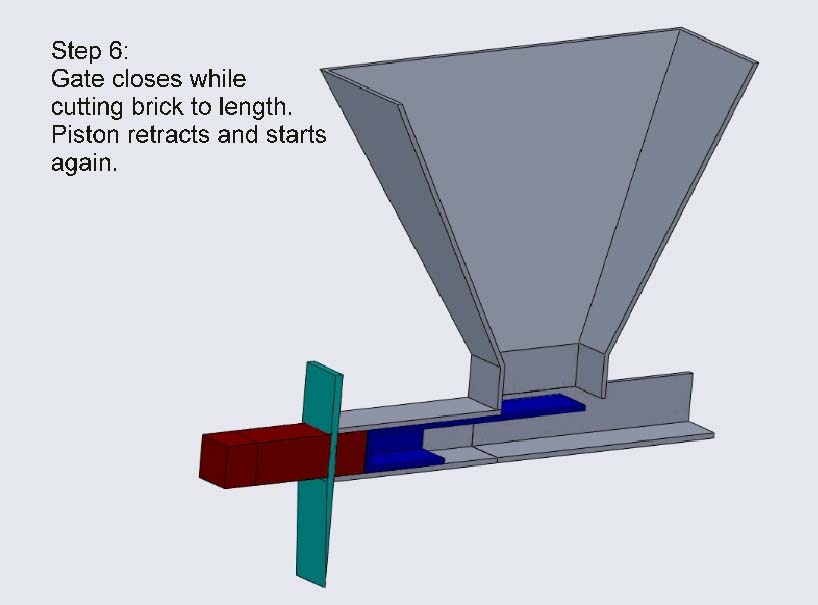

At the beginning of the process the piston would be cycled till a certain amount of pressure had been exerted on the material. This would be done by watching a gauge. Once this was accomplished, the pressure would be released. A gate/cutter would then be opened at the exit. The piston would be advanced one brick length and the gate lowered to cut off a brick. That's it. Simple.

This cycle would then be repeated over and over again.

Other than being much simpler to build than the existing design, it also has other benefits. One is that the pressure exerted on the brick can be altered for different mixtures if need be and the density of the bricks will always be the same because the piston is stopped when a pressure point is reached not after traveling a certain distance. Two, the size of the brick could be adjusted if need be. Neither one of these abilities are present or practical in the existing design.

The existing design puts a certain charge of dirt into the form and stops pushing when the desired shape is reached. If there happens to be some fluctuation in the density of the dirt going in, the bricks will not be consistent.

This design I'm bringing forward is also a good candidate for a non powered, fully manual press (Category 1). One could envision building a unit that is half the size of the existing one that would be easier to carry around. The ram or piston could possibly be lever operated or screw operated via a crank handle.

I'll work on a concept model to make it easier to visualize.

Does this sound interesting? Can anyone think of any shortfalls to my design?

Cheers,

The Dawg

-

22 Comments sorted by

-

A question from a brief skimming. Will the cutter work evenly, or will it risk popping off odd shaped chunks? CEBs tend to need a high proportion of clay, which occasionally behaves oddly.

The ability to vary size and shape would be important depending on the intended uses of the CEBs.

How do you project the modified press would compete with the present in terms of bricks/hour?

Also, how does our design and your proposed design compete with commercial designs like these http://www.adobemachine.com/ ?

If I knew more, I'd've done this research myself, but I lack the ability to look at a machine and understand it, I ned some helping along. -

We might have to play around with different blade types before we find something that works best. A thin straight blade should slice cleanly through a brick. But, if not we could try a slanted knife or even a thin wire.

The small cross section would remain the same actually. But you would be able to make the bricks longer if desired.

I think the limiting factor speed wise is the rate at which earth falls from the hopper. But this design eliminates one step so it's quite likely that it will be faster.

As for commercial designs, I'm not sure really. I've watched the odd one running on U-tube and they seem to be comparable the our existing design.

The Dawg -

Hi Dawg,

Please take a look at Auroville's CEB press (see this discussion about alternate CEB press designs). What could we learn from them?

Thanks,

Elifarley -

I had some time tonight to model my idea. Here is a series of diagrams showing the concept. This would be way easier to construct and will make the same bricks our current press is making.

The DawgAttachments

ceb001a.jpg 92K

ceb002a.jpg 74K

ceb003a.jpg 81K

ceb004a.jpg 85K

ceb005a.jpg 89K

ceb006a.jpg 39K -

There are several ways we could run this style of machine. If we did decide to cut the bricks, which has some advantages, I suspect the piston would need to be somewhat pointy. The reason being is we want a good bond between the left over compressed material and the new loose material being added to the form. If the piston was flat, it might cause the brick to crack at the join. We don't want a fracture line so to speak. It's possible that as long as the same pressure is used that they will combine just fine but better safe than sorry I think.

Another way this could be done is to simply calibrate the movements so it makes a finished brick and the gate would simply allow the brick to escape without the need to cut. In this case, perhaps an adjustable gate at the bottom of the hopper could be used to vary the charge going into the chamber. This would probably work best for the human powered version.

The Dawg -

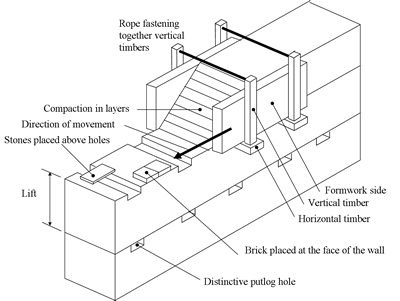

You are still thinking too high tech for a level 1 design. A good part of the world's buildings are "rammed earth", which are monolithic walls (instead of blocks) compressed between movable forms. The modern version uses a concrete mixer to blend the ingredients (including cement if you add it), a front end loader to get the dirt to the top of the wall, and engine powered trench rammers, but it can be done entirely manually. A manual ram can be just a metal rod with a small foot plate welded to one end, and some handles. The mass of the rod does the compression by impact load, rather than steady pressure in the CEB machines.Attachments

formwork_400.png 96K RammedEarth.JPG 29K -

@ Daniel - Now there is a neat concept. I've never seen this before. I wonder what would be the main advantage of this type of construction? There surely are advantages to using bricks. For one, you can make them a head of time and store them for when you have the need. This is a great thing when you have free time to kill and you want to do something useful. I think the bricks would be more versatile in terms of the variety of shapes they can create easily. It doesn't look like that thing would go around corners very well....:)

Category 1 refers to a simple version of a design, not a simple method of building per se. So we can have a category 1 version of the monolithic wall machine and a brick press. I'm aiming for a man powered press although as I mentioned above the same concepts can be used in the more sophisticated version.

Start a new thread and see if you can include some links on actual implemented versions of your great idea. It may prove to be a better choice in some circumstances.

The Dawg -

@ ARGHaynes - Well I don't know. The challenge with that system of building would be to produce a wall with a consistent density. Hand ramming dirt is not going to be as homogeneous as a machine made brick. Plus you will never be able to apply the same high levels of pressure as a machine can. But in the end, so what, as long as there is a way of compensating. Like making the wall wider for instance.

In the end I think the bricks are more versatile. Also, because they are potentially a mass produced item they become a commodity that can be sold easily. Especially if high standards of quality are met. You can stock pile them like money in the bank. Bonus!

The Dawg -

@Dawg - It's not my great idea *smile* rammed earth has been around for 3000 years and accounts for 30% of the homes on the planet. For curves and corners you just need different shaped forms. The main advantages are you can get by with minimal equipment if you go all manual, and a monolithic wall does not have a million cracks to fill like you do with block. It will be slow of course. Modern rammed earth builders can get the walls up in a few days, but that's using power equipment.

Your initial idea of lower tech solutions is valid though. The full up CEB press can produce 1500 blocks a day in theory. That means it can produce enough blocks for a house and shop in a week or so. So it is vast overkill for a single household, or even a village. It's a town sized machine

@ARGHaynes - both CEB and monolithic are compressed earth, the only difference is the unit size. Both can use cement as a stabilizer if you want higher strength than the basic soil mix gives. -

@Daniel- I will accept that 30% of homes are rammed earth, but what percentage of those homes exist in a society that is technologically modern? I might suggest that the majority of rammed earth homes are just one step above temporary. The fact that bricks can be stockpiled and transported means that they are (as Dawg mentioned) a commodity, meaning that they become more than a process or structure, they become an element of a larger economy. The goal is not to simply provide shelter, but provide the opportunity to plug into the global economy (even if on a small scale) with a productive industry, like brick making. If you begin using cement (or any of the several other common materials) as a stabilizer, the price jumps drastically.

I think the important element of the "CEB vs Rammed Earth pseudo-debate" is that rammed earth is a process whereas the CEB is a tool that produces a product. In terms of the scope of the GVCS, the CEB fits. -

@ Daniel - Well I meant you brought the idea forward....:)

One other thing to consider here is that a brick is something the 1st world understands. What you make it out of is erelevant as long as it has the right characteristics. So if it looks like a duck and quacks like a duck it must be one. This will help in getting building permits and the like. We can't assume we're building in the developing countries. We need to build more economic homes here also.

I must say I totally agree with the overkill aspects of the CEB press as it stands today. This surely isn't meant to put down anything others have done so far. I applaud their efforts if for no other reason than to have the transferable skills when we really do need the automation. But ya, unless someone is going to start a brick making business as their main form of income it's plenty fast just using manual hydraulics. They found it was a challenge just trying to feed the hopper at those speeds. After all, we're not trying to create centralized production here. Quite the opposite, as I understand it.

I would rather see many presses being built close to where they're going to be used rather than one monster press working night and day shipping bricks hundreds of miles. We have that now with all the associated transportation costs in tow. We're trying to shift to local production and in the process shift the power back to the middle class.

Respectfully,

The Dawg -

I'm new-thanks for letting me join.

For Dawg on CEB:

1. to solve the problem of blocks not having the same density or volume could you do a 2-stage compression with your horizontal piston? First stage is a preliminary compression at say 1/3 the final pressure & the block is cut to length at this point, recycling the extra dirt. Hopefully this stage puts a uniform amount of dirt in all blocks and it is easy to cut them off. then the second stage does the final compression to uniform size (& hopefully uniform density).

2. Despite #1, it seems I read somewhere that blocks should be compressed in the same direction that they will be loaded...I'd have to go back and troll through a lot of literature to verify that, though.

3. Since water is a threat to ceb in wet climates there needs to be a way to mix cement or lime or fly ash before pressing. Some commercial units have aded mixers during the time (years) i have been following this. Problem though: inhalation of any of these dusts is health hazard. I tried to buy a small amount of fly ash for experimentation several years ago before the big spill in TN, but the concrete company would not sell it to me. they have to release it directly into the mixer under controlled conditions that do not release any dust. thus , you can't just dump it on the ground or pile and turn it in with a tractor/tiller--trying to mix it wet would really change the nature of the blocks. I recall Marcin has made some stabilized block but didn't let it cure long enough before strength testing--I don't know how he mixed the cement in with the dirt. -

@ARGHaynes - Rammed earth is a wall technology. It has nothing to do with what you put inside the rest of the home. The fact that many old houses were built that way and are still around just shows they last a long time. New homes are being constructed using rammed earth and are fully modern: http://www.earth-auroville.com/maintenance/uploaded_pics/6-Rammed-earth-modern-En.pdf

You cannot transport unstabilized block any significant distance, because the only thing holding it together is the electrostatic charge of the clay particles in the mix. This is why a soil mix with no clay will not work at all. Cement grows a network of crystals as it cures, which does a better job locking the other bits in the mix together. Try driving down the road with unstabilized CEB blocks, and you will find they tend to revert to a pile of soil. So practical CEB unstabilized block production will mean driving the press to the construction site, cranking out a bunch of blocks, and then leaving them for the home builder to assemble into walls on their own schedule. Driving the machine to the construction site is less total mass than transporting the blocks, assuming you have suitable soil on site.

I'm working on a solar furnace concept to make cement out of carbonates (ie limestone). This both will emit less CO2 (cement production account for 7% of global CO2 emission), and lower the cost. Producing cement is a simple process, it just takes a lot of heat, and commercial cement plants use fossil fuels to run their kilns, which drives the cost up. Even CEB walls need a foundation to keep them dry, and that needs to be a building material that doesn't get mushy when wet, and not suck too much water up by capillary action.

@ Ken - the rammed earth projects I have done mixed the cement in dry along with the soil in a concrete mixer, so it is just as dusty and messy as any other concrete work on a small scale. If the soil has enough moisture in it, it will start curing without any added water. If you are not in a very dry climate, moisture from the air will continue the process. Stabilized rammed earth will cure to a reasonable strength in 28 days, but continue to get stronger for years. Traditional concrete gets its initial strength much faster (days to a week). It also continues to gain strength for years, just time shifted to get a higher percentage of strength earlier, because you added enough water to the mix to make the reaction happen faster.

CEB does not *have* be stabilized, but if not you need some combination of roof, foundation, and wall coating to keep the water away. -

@Daniel: we are agreed that it is dusty. I was just suggesting the need for a low-dust mixing device--particularly if using free, recycled, no-extra-embeded-energy fly ash with its heavy metal content. I live in wet East Tennessee where CEB has not gained a footing, so stabilized block would be particularly important.

I'm also interested in your solar carbonate furnace. Given the high mass and temperatures required it seems a long time would be required to do a batch. Of course, if you had some way to actively reduce the pressure of carbon dioxide (vacuum pump?) you might be able to help "pull" the reaction along--but the pump would require energy too so maybe good venting would be best. It should be possible to do an exploratory calculation on the effect of pressure reduction; let me know if you are interested.

An alternative approach I heard about comes from a century or more ago in Texas: mix ground limestone with sour milk (which Texans could get in quantity and which contains lactic acid). Lactic acid + calcium carbonate forms calcium lactate + carbon dioxide. This made a weak mortar that was used in a classic old two-story home in Austin that had about 2-foot thick stone walls--some of which were underground in a French drain. I knew the owner who was rebuilding the house and he was replacing the mortar with portland, but it had held up for at least a hundred years. I believe this old type of mortar "sets" when the calcium lactate absorbs carbon dioxide from the air slowly to re-form calcium carbonate. Other weak acids such as acetic acid (in vinegar) would probably work the same way but I doubt if strong acids like sulfuric, nitric, hydrochloric, etc would reform the carbonate over time.

-

@dawg check out the new block press by Yanmar (google for "714 Dynablock"). compare this to the Fernco Metals block press that is operated off compressed air. You expressed earlier somewhere on the fef site the idea of a trailer that could back up to a pile of dirt and from the trailer load the dirt into the press. I liked that. Also, by using a screw to lift the dirt up to the dirt hopper, you could also admit at the bottom of the screw a measured amount of stabilizer (lime, portland, fly ash) vis a second screw so that stabilizer and dirt would be mixed while being lifted--avoiding the cost of a mixer .

-

here is another manual press video http://youtu.be/LON40kaKFEw

-

I haven't logged in here for a while. Working on my own Open Source site lately. So sorry for no replies gentlemen.

I really feel that a manual press is all one needs to make enough bricks for a neighborhood. Considering the fact that stabilized bricks are the only safe way to build standard wall structures, I figure the time it takes to premix at the front end of the process gives plenty of time for manual pressing at the end.

The only reason you would need a fancy computerized CEB press is if you were going to supply bricks for thousands of homes. That's not supposed to be the goal here. We're trying to DE-centralize industrial processes not recreate the big business world we already have.

So yes, a high quality Open Source CEB press should be a priority I think. If no one else does it, I will eventually design and build one at OSRL.

@Metz - Great links. The more I see of this style of machine, the more I like it.

Cheers,

The Dawg

-

Thanks,

I think it will go well in the Philippines. Although at the present the engineer types don't see the usefulness of using the Brazillian CEB model. The complaint so far is the long cure times.

I am mystified as to the present factor e farm CEB construction method. Using stabilized interlocking bricks that are glued together seems to be a faster, safer method. I grew up in the Midwest, I don't see how unstabilized blocks will survive a wet Midwestern spring very well. I also see them using topsoil instead of subsoil and it has a lot of organic material in it.

I thought that was a no no.

-

@Metz - For better or worse, OSE is totally controlled by one man. This guy knows a little about many things. He is "educated" after all. I'm sure he figures he's brilliant. I'm afraid I no longer agree with that statement.

So....very bad decisions are being made left and right. Lies and more lies around every corner. People are being taken advantage of and even hurt. Hurt emotionally and physically. The working conditions at FeF are appalling and dangerous. Ask ANYONE who has been there.

There is no reason for building in this fashion. OSE had plenty of time to research the alternatives and commit the funds. Of course now they're in a panic because winter is coming. This is the reason given for cutting corners, if you can call what they are doing, that. It's just nutty.

Just to make things clearer for you.....:)

Dawg

-

I can see that by the videos. Im not pulling my financial support. But the guy needs to get out of the shop and make the transition from being a hands on worker to being a leader. He cant be both the Sgt and the Commanding officer. Easier said than done, but he does have a lot of good will, willing volunteers online, and resources that are being squandered. In short the whole thing needs a good organized project manager.

A lot of new tech developments have come up the past couple years. However working in the shop, leaves little time to keep abreast of new developments and one can find themselves making decisions based on old information.

-

@mjn I got blueprints and a instructional manual now. However I contacted the foundation that authored the document and they dont want it reworked and published in a Wiki. They are not distributing the plans themselves however. The letter I got back indicated they were looking to somehow put the info online themselves. I suspect that someone in the organization that took over there thinks they can turn the how to manuals they used to give away for free into money.

I emailed you a copy of the PDF awhile back. Copyright wont be a issue if we rewrite the information. Facts and instructions like recipes cant be copyrighted.

The machine was originally designed in the 1950's so there is prior art which means that patents will not be a issue either.

It prob would take a good long afternoon to combine the sahara press instructions with the other plans I sent to make a good functional wiki. We would need someone to draft a new blueprint to keep the copyright issue at bay.

-

@metz - Well, I've created a wiki project page at OSRL for this. If you would kindly deal with the creation of fresh text, I will commit to generating a full 3D model of it and high quality drawings. Can I put you on the team list for this project?

Dawg

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Categories

- All Discussions1,013

- General Discussion895

- ↳ Introductions145

- ↳ GVCS Development43

- ↳ GVCS Replication14

- ↳ Similar Projects, Partnerships and Open Culture53

- ↳ In the News14

- ↳ Education15

- ↳ Food18

- ↳ Energy42

- ↳ Health2

- ↳ Sustainable Architecture21

- ↳ Transportation10

- ↳ Household6

- ↳ IT, Web Infrastructure110

- ↳ Shared Personal Notes1

- ↳ New Communities10

- ↳ Other Languages34

- Project Management4

- Proposal and Development Status10

- Organizational Development26

- ↳ Team Logs4

- ↳ OSE Core Team1

- ↳ OSE IT - Core Team2

- ↳ OSE Collaboration Platform - Core Team6

- ↳ Resource Development3

- GVCS Technical Development52

- ↳ Open Source Car10

- ↳ Open Source Tractor1

- ↳ Gasifier Burner1

- ↳ CNC Torch Table5

- ↳ Agricultural Microcombine4

- ↳ Dimensional Sawmill1

- ↳ Documentation and Instructionals18

- OSE Dev0

- ↳ Trucktor0

- ↳ Microtrac0

- ↳ CNC Router0

- ↳ CNC Torch Table0

- ↳ Bulldozer0

- ↳ Backhoe0

- ↳ Car0

- ↳ 3D Printer0

- ↳ 3D Printer Laser Diode0

- ↳ Tractor0

- ↳ Powercube0

- ↳ Brick Press Controller0

In this Discussion

Tagged

Loading